Difference between revisions of "Construction: communication, inspection plan, and utilities coordination"

Kyle menken (talk | contribs) |

Kyle menken (talk | contribs) m |

||

| Line 40: | Line 40: | ||

*Material testing requirements and their timelines must be understood by all parties, including who is responsible for testing. | *Material testing requirements and their timelines must be understood by all parties, including who is responsible for testing. | ||

*Material acceptance protocols, with chain of custody, should be understood by all parties, including who is responsible if the material fails. | *Material acceptance protocols, with chain of custody, should be understood by all parties, including who is responsible if the material fails. | ||

*Biomedia manufacturing and testing should start prior to construction, ideally 2 months in advance. | *[[Bioretention: Filter media|Biomedia]] manufacturing and testing should start prior to construction, ideally 2 months in advance. | ||

|- | |- | ||

|'''Access routes and storage areas'''|| | |'''Access routes and storage areas'''|| | ||

| Line 64: | Line 64: | ||

|- | |- | ||

|'''Plant establishment and warranty-period maintenance'''|| | |'''Plant establishment and warranty-period maintenance'''|| | ||

*Discuss planting timelines at the pre-construction meeting. | *Discuss [[Plant selection|planting]] timelines at the pre-construction meeting. | ||

*Avoid planting in the summer months (June, July and August). Fall planting is the ideal scenario. | *Avoid planting in the summer months (June, July and August). Fall planting is the ideal scenario. | ||

*Plants will require regular maintenance (irrigation and weeding) to ensure establishment, especially over the first year. | *Plants will require regular maintenance (irrigation and weeding) to ensure establishment, especially over the first year. | ||

Latest revision as of 14:18, 10 August 2022

After securing a contractor, a pre-construction meeting between the project manager, project engineer, and contractor will facilitate an efficient job site and reduce the potential for miscommunication. These meetings should cover:

- LID design details and construction notes

- material specifications, inspections, and chain-of-custody

- access routes and storage areas

- protection of LID practices: phasing, ESC, and perimeter fencing

- equipment requirements and recommendations

- verification of field changes

- plant establishment and warranty-period maintenance

- ownership and assumption protocols

- project inspection plan

- verification processes for field changes to the design and material substitutions

The table below expands upon the bullets above and provides helpful guidance on communication topics at the pre-construction meeting. Given the lead-up time needed for testing requirements of specified materials, these discussions should occur soon after the contract is awarded, ideally 2 months prior to project construction.

| Communication topic | Guidance |

|---|---|

| LID design details and construction notes |

|

| Material specifications, inspections, and chain-of-custody |

|

| Access routes and storage areas |

|

| Protection of LID practices during construction: phasing, ESC, and perimeter controls |

|

| Equipment requirements and recommendations |

|

| Verification of field changes |

|

| Plant establishment and warranty-period maintenance |

|

| Ownership and assumption protocols |

|

| Project inspection plan |

|

Inspection plan[edit]

The inspection and maintenance page gives detailed guidance on how to conduct construction inspections for LID practices. Generally, construction inspections should be continuous as the work progresses. If this isn’t possible, critical inspection points are:

- site preparation

- excavation

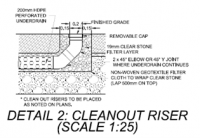

- installation of pipes, granular, and biomedia

- finishing grades

- surface treatment installation: pavers, plants, porous concrete, etc.

- after rain events (see ESC inspection and maintenance)

- whenever sub-contractors or utilities begin work (hand-off points)

The last element—inspection of sub-contractors—requires further comment. For example, if a sub-contractor is installing the curbing, they need to understand the purpose of the curbing and curb cuts, i.e., that they are meant to direct water into the LID facility, not to the closest catch basin. Without this knowledge, the sub-contractor may mistakenly build the curbs as they usually do: to direct water into a catchbasin.

Utilities coordination[edit]

Similarly, if the LID practice is in close proximity to sub-surface utilities, the utility owner may use their own contractors to perform related work. If this is the case, these sub-contractors must also be made aware of the LID practice’s purpose, how compaction affects performance, keeping the LID practice clear of excavated dirt and generally how their work could impede the construction and performance of the LID practice. In general, communication between the contractors, project managers, and project engineers should be frequent and open.