Difference between revisions of "Inspection and Maintenance: Underground Infiltration Systems"

| (5 intermediate revisions by the same user not shown) | |||

| Line 156: | Line 156: | ||

# After every large storm event (e.g., 15 mm rainfall depth or greater) to ensure ESCs and pretreatment or flow diversion devices are functioning and adequately maintained. View the table below, which describes critical points during the construction sequence when inspections should be performed prior to proceeding further. You can also download and print the table [https://wikidev.sustainabletechnologies.ca/images/a/a6/LID-IM-Guide-7.5-Underground-Infiltration-Systems.pdf '''here''']<br> | # After every large storm event (e.g., 15 mm rainfall depth or greater) to ensure ESCs and pretreatment or flow diversion devices are functioning and adequately maintained. View the table below, which describes critical points during the construction sequence when inspections should be performed prior to proceeding further. You can also download and print the table [https://wikidev.sustainabletechnologies.ca/images/a/a6/LID-IM-Guide-7.5-Underground-Infiltration-Systems.pdf '''here''']<br> | ||

</br> | </br> | ||

[[File:Catchbasin isnert underground.PNG|thumb|400px|A [[pretreatment]] device ( | [[File:Catchbasin isnert underground.PNG|thumb|400px|A [[pretreatment]] device (hydrodynamic (i.e., oil and grit) separator) upstream of an underground infiltration system inlet in need of cleaning out. These devices are designed to limit the amount of trash, debris, sediment, oil and grease entering the infiltration system, which helps to prevent clogging and maintain its drainage performance (Source: TRCA, 2018<ref name="example1" />).]] | ||

{| class="wikitable" style="width: 800px;" | {| class="wikitable" style="width: 800px;" | ||

| Line 211: | Line 211: | ||

==Routine Maintenance - Key Components and I&M Tasks== | ==Routine Maintenance - Key Components and I&M Tasks== | ||

Regular inspections (twice annually, at a minimum) done as part of routine maintenance tasks over the operating phase of the BMP life cycle to determine if maintenance task frequencies are adequate and determine when rehabilitation or further investigations into BMP function are warranted. | Regular inspections (twice annually, at a minimum) done as part of routine maintenance tasks over the operating phase of the BMP life cycle to determine if maintenance task frequencies are adequate and determine when rehabilitation or further investigations into BMP function are warranted. | ||

Periodic inspections done every 5 years (maintenance verifications) and every 15 years (performance verifications) post-construction over the operating life cycle of the BMP to ensure compliance with the maintenance agreement (e.g., [https://www.ontario.ca/page/environmental-compliance-approval Environmental Compliance Approval permit]) conditions, evaluate functional performance and determine when rehabilitation or replacement is necessary. | |||

Requirements of the Ontario Occupational Health and Safety Act regulation for individuals working in confined spaces ([https://www.ontario.ca/laws/regulation/050632 O.Reg. 632/05]) must be adhered to during any inspection or | |||

maintenance work on underground infiltration systems that involves entry into confined spaces (e.g., catchbasins, manholes, access hatches). Individuals working in such environments should be adequately trained on the use and maintenance of the necessary safety equipment and review hazards and safety plans regularly. Further information about Ontario’s Confined Spaces Regulation and Guideline can be accessed here: [https://www.ontario.ca/document/guideline-working-confined-spaces Confined Spaces Guideline - Ministry of Labour, Immigration, Training and Skills Development]. | |||

Table below describes routine maintenance tasks for underground infiltration systems ([[infiltration chambers]], [[infiltration trenches]], [[bioswales]], etc.) organized by BMP component, along with recommended minimum frequencies. It also suggests higher frequencies for certain tasks that may be warranted for BMPs located in highly visible locations or those receiving flow from high traffic (vehicle or pedestrian) areas. Tasks involving removal of trash, debris and sediment and weeding/trimming of vegetation for BMPs in such contexts may need to be done more frequently (i.e., higher standards may be warranted). | Table below describes routine maintenance tasks for underground infiltration systems ([[infiltration chambers]], [[infiltration trenches]], [[bioswales]], etc.) organized by BMP component, along with recommended minimum frequencies. It also suggests higher frequencies for certain tasks that may be warranted for BMPs located in highly visible locations or those receiving flow from high traffic (vehicle or pedestrian) areas. Tasks involving removal of trash, debris and sediment and weeding/trimming of vegetation for BMPs in such contexts may need to be done more frequently (i.e., higher standards may be warranted). | ||

| Line 229: | Line 234: | ||

*Remove trash, debris and sediment from pavements (biannually to quarterly) and eavestroughs (annually); | *Remove trash, debris and sediment from pavements (biannually to quarterly) and eavestroughs (annually); | ||

*Replant or seed bare soil areas as needed. | *Replant or seed bare soil areas as needed. | ||

|[[File:CDA | |[[File:CDA pass underground.PNG|300px|thumb|center|CDA has not changed in size or land cover. Sediment, trash or debris is not accumulating and point sources of contaminants are not visible.]] | ||

|[[File:CDA | |[[File:CDA fail underground.PNG|280px|thumb|center|Point sources of contamination are present (i.e. accumulated sediment and debris from melted snow piles)]] | ||

|- | |- | ||

|'''[[Pretreatment]]''' | |'''[[Pretreatment]]''' | ||

| | | | ||

Devices or features that retain trash, debris and sediment, oil and grease; help to prevent obstructions and [[clogging]] of the infiltration area. Examples are eavestrough screens, [[Pretreatment|catch basin]] inserts (screens, baffles, | Devices or features that retain trash, debris and sediment, oil and grease; help to prevent obstructions and [[clogging]] of the infiltration area. Examples are eavestrough screens, [[Pretreatment|catch basin]] inserts (screens, baffles, filters) and sumps, [[oil and grit separators]], [[inlets|geotextile-lined inlets]], filters, isolator rows, and water quality [[forebay]] units. | ||

| | | | ||

*Remove trash, debris and sediment annually to biannually or when the device sump is half full; | *Remove trash, debris and sediment annually to biannually or when the device sump is half full; | ||

*Measure sediment depth or volume during each cleaning, or annually to estimate accumulation rate and optimize frequency of maintenance. | *Measure sediment depth or volume during each cleaning, or annually to estimate accumulation rate and optimize frequency of maintenance. | ||

|[[File: | |[[File:Pretreatment inlet pass underground.PNG|280px|thumb|center|[[Geotextile]]-lined stone inlet is free of sediment, trash and debris. Stones to slow down and spread out inflowing water remain in place.]] | ||

|[[File: | |[[File:Pretreatment inlet Fail underground.PNG|300px|thumb|center|Accumulated sediment, trash and debris in the hydrodynamic (i.e., oil and grit) separator is occupying greater than 50% of its storage capacity. (Photo Source: SWC Canada, 2020)<ref>Storm Water Compliance (SWC) Canada Inc. 2020. OIL GRIT SEPARATORS/WATER QUALITY STRUCTURES. Accessed 02 August 2022. https://www.swccanada.com/system-types/oil-grit-separators</ref>]] | ||

|- | |- | ||

|'''[[Inlets]]''' | |'''[[Inlets]]''' | ||

| Line 248: | Line 253: | ||

*Remove trash, sediment and debris biannually (spring and late fall) to quarterly (spring, summer, early fall, late fall/early winter); | *Remove trash, sediment and debris biannually (spring and late fall) to quarterly (spring, summer, early fall, late fall/early winter); | ||

*Make note of sediment depth or volume during each cleaning or annually to estimate accumulation rate and optimize frequency of maintenance. | *Make note of sediment depth or volume during each cleaning or annually to estimate accumulation rate and optimize frequency of maintenance. | ||

|[[File: | |[[File:Inlets pass underground.PNG|285px|thumb|center|There are no obstructions at the inlet and stormwater can freely flow into the BMP.]] | ||

|[[File: | |[[File:Inlets fail underground.PNG|300px|thumb|center|Sediment has accumulated in the inlet pipe to the infiltration trench and is fully obstructing flow of stormwater into the BMP.]] | ||

|- | |- | ||

|'''[[Overflow|Overflow Outlet]]''' | |'''[[Overflow|Overflow Outlet]]''' | ||

| Line 257: | Line 262: | ||

*Keep free of obstructions; | *Keep free of obstructions; | ||

*Remove trash, sediment, debris, oil and grease biannually (spring and late fall) to quarterly (spring, summer, early fall, late fall/early winter). | *Remove trash, sediment, debris, oil and grease biannually (spring and late fall) to quarterly (spring, summer, early fall, late fall/early winter). | ||

|[[File: | |[[File:Outlet & overflow pass underground.PNG|320px|thumb|center|The overflow outlet weir wall and storm sewer pipe in the control manhole of this infiltration chamber system is free of damage and obstruction and functions as designed to safely convey excess water from the BMP.]] | ||

|[[File:Overflow Fail p.p.JPG|280px|thumb|center| | |[[File:Overflow Fail p.p.JPG|280px|thumb|center|Sediment and debris has accumulated in the overflow outlet pipe which impairs its function to convey excess water from the BMP.]] | ||

|- | |- | ||

|'''[[Underdrain|Sub-drain]]''' | |'''[[Underdrain|Sub-drain]]''' | ||

| Line 265: | Line 270: | ||

| | | | ||

*Keep perforated pipes and flow restrictors free of obstructions; | *Keep perforated pipes and flow restrictors free of obstructions; | ||

*Inspect flow restrictor and flush with a garden hose or pressure washer regularly (biannually to quarterly) | *Inspect flow restrictor and flush with a garden hose or pressure washer regularly (biannually to quarterly). | ||

|[[File:Underdrain | |[[File:Underdrain pass underground.PNG|310px|thumb|center|The sub-drain outlet pipe from the infiltration chamber system is not obstructed by sediment, debris or roots and shows no signs of damage.]] | ||

|[[File:Underdrain | |[[File:Underdrain fail underground.PNG|300px|thumb|center|A perforated pipe in an exfiltration storm sewer system is clogged by sediment and debris which inhibits its drainage function.]] | ||

|- | |- | ||

|'''[[Monitoring well]]''' | |'''[[Monitoring well]]''' | ||

| Line 274: | Line 279: | ||

| | | | ||

*[[Wells|Standpipes]] should be securely capped on both ends and protected from damage by vehicular traffic or foot traffic by a lockable casing. | *[[Wells|Standpipes]] should be securely capped on both ends and protected from damage by vehicular traffic or foot traffic by a lockable casing. | ||

|[[File: | |[[File:Monitoring well pass underground.PNG|340px|thumb|center|The well is undamaged and accessible and the cap is in place and secured to prevent unauthorized access]] | ||

|[[File: | |[[File:Monitoring well fail underground.PNG|300px|thumb|center|The well was buried during landscaping and found covered only by filter cloth (i.e. cap missing).]] | ||

|- | |||

|} | |||

==Tips to Preserve Basic BMP Function== | |||

*Prohibit stockpiling of [[Soil groups|soil]], [[sand]], [[compost]] or unwashed [[gravel]] within the [[Infiltration: Sizing and modeling|CDA]] and [[inlets]] to prevent [[clogging]] with sediment. | |||

*For BMPs with [[underdrains|sub-drains/underdrains]] and flow restrictors, [[Pretreatment|pretreatment devices]] that prevent floating trash and debris from entering the practice should be used to prevent obstruction of the sub-drain pipe/flow restrictor. | |||

*For BMPs equipped with [[pretreatment]] that detains floating contaminants (e.g., oil and grease, trash and debris), such as [[oil and grit separators|hydrodynamic separators/oil and grit separators]] or [[forebays]] with baffle walls, remove trash and debris first using a bucket strainer. Floating oils and grease should then be removed off the top of the water using a vacuum truck. | |||

*Provide a means of draining [[infiltration chambers]] by gravity (e.g., pipe and valve through the control structure weir wall) to make [[inspection and maintenance]] work that requires drainage of the BMP (e.g., filter bed and control structure inspection and sediment removal, repairs to control structure) easier to perform. | |||

*To remove accumulated sediment from [[underdrain]] pipes and chamber system units, a hydrovac truck equipped with a JetVac nozzle should be employed that uses pressured jets of water to propel itself through the structure while scouring and directing suspending sediments to a collection point. As the nozzle is retrieved, the sediment is flushed into the manhole or catchbasin sump for removal by vacuuming. Selecting an appropriate JetVac nozzle will depend on the structure being cleaned. For chamber system units, fixed nozzles designed for culverts or large diameter pipe cleaning with rear-facing jets are preferable (consult product manufacturer for further guidance). | |||

==Rehabilitation & Repair== | |||

Table below provides guidance on rehabilitation and repair work specific to underground infiltration systems organized according to BMP component.<br> | |||

</br> | |||

[[File:Underdrain clogded underground.PNG|thumb|340px|The manhole sump is becoming filled with sediment, trash and excess and debris, which is beginning to impair flow of stormwater into the [[perforated pipe]] of the [[exfiltration trench|exfiltration storm sewer system.]]]] | |||

{|{| class="wikitable" style="width: 900px;" | |||

|+'''Underground Infiltration Systems: Key Components, Typical Issues and Rehabilitation Requirements''' | |||

|- | |||

!Component | |||

!Problem | |||

!Rehabilitation Tasks | |||

|- | |||

| rowspan="2"|'''[[Underdrains|Sub-drain/Underdrain]]''' | |||

|Sub-drain perforated pipe is obstructed by trash, debris, sediment or roots | |||

| | |||

*Schedule hydro-vac truck or drain-snaking service to remove the obstruction. | |||

|- | |||

|Perforated pipe caps are missing or damaged | |||

| | |||

*Replace missing or damaged caps. | |||

|- | |||

|'''[[Forebays|Isolator Row or Water Quality Forebay Unit]]''' | |||

| | |||

Sump is ≥ half full or average sediment depth is ≥ 8 cm | |||

| | |||

*Schedule maintenance work; First remove floating trash and debris by bucket strainer, then oil and grease by petroleum absorbing sponge. Then fully drain the row or unit by gravity, pumping or vacuuming, and remove accumulated sediment through use of a hydro-vac truck equipped with JetVac nozzle. | |||

|- | |- | ||

|'''Manhole control structure''' | |||

| | |||

Structure or pipe connection is leaking and impairing the water storage capacity or function of the BMP | |||

| | |||

*Schedule work to repair cracks or seal leaking components. The BMP may need to be fully drained to make such repairs. | |||

|} | |} | ||

==Inspection Time Commitments and Costs== | |||

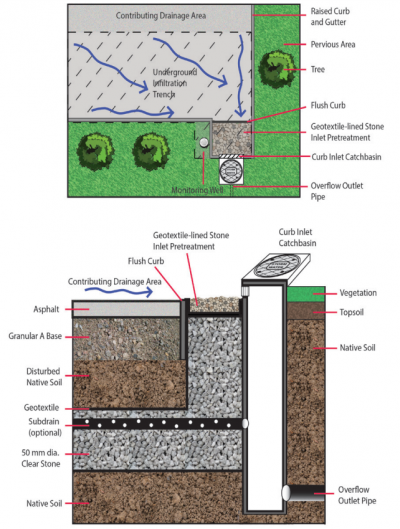

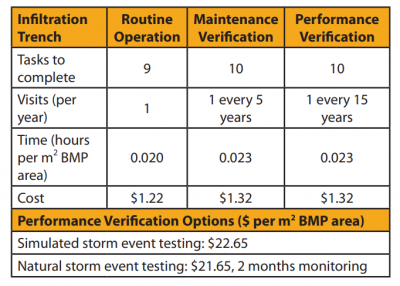

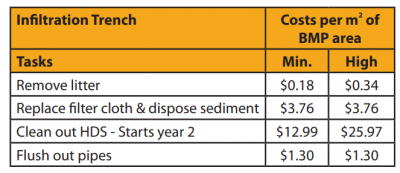

Estimates are based on a typical [[infiltration trench]] design that receives roof and road runoff and includes a [[oil and grit separators|hydrodynamic separator]] as pretreatment; estimates for [[infiltration trenches]] that receive roof runoff only are described in the [https://sustainabletechnologies.ca/app/uploads/2016/08/LID-IM-Guide-7.5-Underground-Infiltration-Systems.pdf Low Impact Development (LID) Stormwater Management Practice Inspection and Maintenance Guide]<br> | |||

</br> | |||

[[File:Time & cost estimates underground.PNG|thumb|left|400px|General time commitments and costs for inspection of underground infiltration systems designed to receive roof and road runoff and includes a [[Oil and grit separators|hydrodynamic separator]] as pretreatment (in 2016 $ figures)<ref name="example2">TRCA. 2018. Inspection and Maintenance of Stormwater Best Management Practices. Underground Infiltration Systems - Fact Sheet. https://sustainabletechnologies.ca/app/uploads/2018/02/Underground-Infiltration-Systems-Fact-Sheet.pdf</ref>.]] | |||

[[File:Task cost underground.PNG|thumb|400px|Per-task cost estimates for maintenance and rehabilitation of underground infiltration systems designed to receive roof and road runoff and includes a [[Oil and grit separators|hydrodynamic separator]] as pretreatment (in 2016 $ figures)<ref name="example2" />.]] | |||

[[File:Construction & life cycle underground.PNG|thumb|center|400px|Construction and life cycle cost estimates for underground infiltration systems designed to receive roof and road runoff and includes a [[Oil and grit separators|hydrodynamic separator]] as pretreatment (in 2016 $ figures)<ref name="example2" />.]]<br> | |||

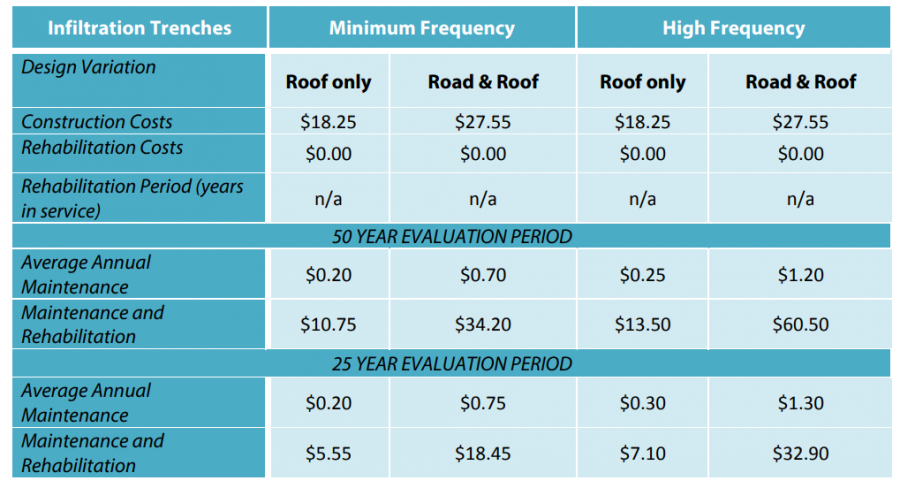

Estimates of the life cycle costs of inspection and maintenance have been produced using the latest version of the [[Cost analysis resources|LID Life Cycle Costing Tool]] for two types of underground infiltration systems: | |||

[[infiltration trenches]] and [[infiltration chambers|infiltration chamber systems]] to assist stormwater infrastructure planners, designers and asset managers with planning and preparing budgets for potential LID features. | |||

Assumptions for the above costs and the following table below are based on the following: | |||

*For underground infiltration systems it is assumed that no rehabilitation work will be needed to maintain drainage performance at an acceptable level over a 50 year period of operation, given that [[pretreatment]] devices are in place upstream and are being adequately maintained. The annual average maintenance cost value represents an average of routine maintenance tasks, as outlined in table, Underground Infiltration Systems: Key Components, Descriptions and Routine I&M Requirements, above. All cost value estimates represent the Net Present Value (NPV) as the calculation takes into account average annual interest (2%) and discount (3%) rates over the evaluation time periods. | |||

*For each type, two design variations have been examined: BMPs designed to receive roof runoff only; and BMPs designed to receive a combination of roof and road runoff. For each system type and design variation, life cycle cost estimates have been calculated for two level-of-service scenarios: the minimum recommended frequency of inspection and maintenance tasks (i.e., Table Visual Indicators Framework - Underground Infiltration Systems and table, Underground Infiltration Systems: Key Components, Descriptions and Routine I&M Requirements, above), and a high frequency scenario to provide an indication of the potential range. | |||

*For all design variations, the CDA is assumed to be composed of a 2,000 m<sup>2</sup> roof for the roof runoff only design variation, and a 500 m<sup>2</sup> roof and 1,500 m<sup>2</sup> impermeable pavement area for the roof and road runoff design. All are sized to retain runoff from a 34 mm rain event and assumed to have a native sub-soil infiltration rate of 34 mm/h. An impervious drainage area to pervious area ratio (I:P ratio) of 20:1 is used to size the BMP footprint area, in accordance with the LID SWM Planning and Design Guide recommendations [https://sustainabletechnologies.ca/app/uploads/2013/01/LID-SWM-Guide-v1.0_2010_1_no-appendices.pdf LID SWM Planning and Design Guide (CVC & TRCA, 2010)]. The infiltration trench is assumed to be 1.630 m deep, 2.0 m wide and 50.0 m long. The infiltration chamber system is assumed to be 1.067 m deep, 8.0 m wide and 12.5 m long. | |||

*For all design variations, the invert of the overflow outlet pipe is located 1.2 m below the surface to protect against frost. Monitoring wells are provided to facilitate inspections. In the roof runoff only design, there is no pretreatment other than a sump in the control manhole which allows for some settling of coarse sediment and debris. In the roof and road runoff design, pretreatment is provided by a hydrodynamic (i.e., oil and grit) separator for the impermeable pavement portion of the CDA. | |||

*Estimates of the life cycle costs of infiltration trenches and chamber systems in Canadian dollars per unit CDA ($/m<sup>2</sup>) are presented above. The LID Life Cycle Costing Tool allows users to select what BMP type and design variation applies, and to use the default assumptions to generate planning level cost estimates. Users can also input their own values relating to a site or area, design, unit costs, and inspection and maintenance task frequencies to generate customized cost estimates, specific to a certain project, context or stormwater infrastructure program. | |||

<br> | |||

</br> | |||

[[File:Minimum high fre cost underground.PNG|thumb|center|900px|Life cycle cost estimates for [[infiltration trenches]] under minimum and high frequency scenarios (in 2016 $ figures).<ref>TRCA. 2016. Low Impact Development Stormwater Management Practice Inspection and Maintenance Guide. Prepared by the Sustainable Technologies Evaluation Program. Vaughan, Ontario. https://sustainabletechnologies.ca/app/uploads/2016/08/LID-IM-Guide-7.5-Underground-Infiltration-Systems.pdf</ref>]] | |||

'''Notes:''' | |||

<small> | |||

#Estimated life cycle costs represent NPV of associated costs in Canadian dollars per square metre of CDA ($/m<sup>2</sup>). | |||

#Average annual maintenance cost estimates represent NPV of all costs incurred over the time period and do not include rehabilitation costs. | |||

#Life cycle costs are higher for BMPs designed to receive roof and road runoff due to additional costs associated with the [[Oil and grit separators|hydrodynamic (i.e., oil and grit) separator]] and associated inspection and routine maintenance. | |||

#Life cycle cost estimates are similar between [[infiltration trench]] and [[infiltration chambers]] system designs, and predicted to be slightly higher for infiltration trenches compared to chamber systems (construction and maintenance costs). | |||

#Maintenance costs over a 25 year time period for roof runoff only infiltration trenches are estimated to be 30.4% of the original construction cost for the Minimum Recommended Frequency maintenance scenario, and 38.9% for the High Frequency maintenance scenario. | |||

#Maintenance costs over a 25 year time period for roof and road runoff [[infiltration trenches]] are estimated to be 67.0% of the original construction cost for the Minimum Recommended Frequency maintenance scenario, and 1.19 times the original construction cost for the High Frequency maintenance scenario. | |||

#Maintenance costs over a 50 year time period for roof runoff only [[infiltration trenches]] are estimated to be 58.9% of the original construction cost for the Minimum Recommended Frequency maintenance scenario, and 74.0% for the High Frequency maintenance scenario. | |||

#Maintenance costs over a 50 year time period for roof and road runoff infiltration trenches are estimated to be 1.24 times the original construction cost for the Minimum Recommended Frequency maintenance scenario, and 2.20 times for the High Frequency maintenance scenario. | |||

</small> | |||

==Inspection Field Data Sheet== | |||

Feel free to '''download''' (downward facing arrow on the top righthand side) and '''print''' (Pinter emoticon on top right hand side) the following Underground Infiltration Systems Inspection Field Data Form developed by TRCA, STEP and its partners for the [https://sustainabletechnologies.ca/app/uploads/2016/08/LID-IM-Guide-2016-1.pdf Low Impact Development Stormwater Management Practice Inspection and Maintenance Guide]<ref>STEP. 2016. Low Impact Development Stormwater Management Practice Inspection and Maintenance Guide. https://sustainabletechnologies.ca/app/uploads/2016/08/LID-IM-Guide-2016-1.pdf</ref>. | |||

The 4 page document prompts users to fill out details previously mentioned above on this page in other sections about various zones associated with [[Infiltration Trenches]], [[Infiltration chambers]], [[Exfiltration trench]], [[Soakaways]], and other associated features (i.e. inlets, CDA, filter bed, outlets, etc.) and describe why each area is a pass or fail, and if remediate action is required and under what timeframe it would be completed by. Furthermore, the forms prompt the reviewer to determine what type of inspection is being conducted for the feature in question: Construction (C), Routine Operation (RO), Maintenance Verification (MV), or Performance Verification (PV). <br> | |||

<br> | |||

[[File:Infiltration chamber underground.PNG|thumb|340px|An [[infiltration trench]] under construction. (Photo Source: TRCA).]] | |||

<pdf width="900" height="800">File:Inspection field data sheet underground.pdf</pdf> | |||

==References== | |||

Latest revision as of 21:31, 4 August 2022

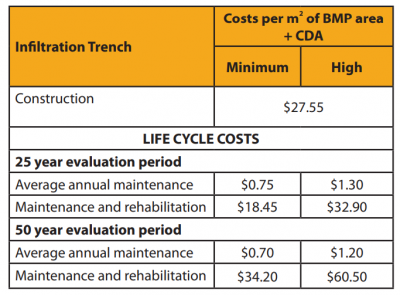

Overview[edit]

Underground infiltration systems is a general term that refers to best management practices (BMPs) that capture and temporarily store stormwater from hard surfaces. These systems treat stormwater by detaining it to allow suspended sediments to settle out and soaking it into the ground where it is filtered and cleansed by interaction with soil. Runoff water is delivered to the practice through pipes connected to catchbasins, hydrodynamic (i.e., oil and grit) separators, filters, manholes, sub-drains of other features or roof downspouts. They are installed below the local maximum frost penetration depth to ensure they continue to drain year-round. Water that is in excess of the storage capacity overflows to an adjacent drainage system (e.g., municipal storm sewer or other BMP), typically via pipe or manhole containing a control structure (e.g., weir wall), to safely convey flows during flood events. Depending on the permeability of the underlying soil, such practices may be designed without a sub-drain for full infiltration or with a sub-drain for partial infiltration. The sub-drain pipe may feature a flow restrictor (e.g., orifice cap, valve) for gradually releasing detained water and optimizing the amount drained by infiltration.

Key components of Underground Infiltration Systems to pay close attention to are the:

Trash, debris and sediment builds up at these locations and can prevent water from flowing into or out of the practice.

Associated Practices[edit]

- Soakaways: Typically service individual lots and receive only roof and walkway runoff but can also be designed to receive overflows from other BMPs (e.g., rain barrels or cisterns, rain gardens, green roofs. Also known as infiltration galleries, French drains, dry wells or soakaway pits.

- Infiltration trenches: Linear oriented soakaways designed to fit into narrow strips of land between structures or properties, or along road rights-of-way; can also receive road runoff with adequate pretreatment devices upstream of inlets.

- Infiltration chambers: Include a range of proprietary modular structures installed underground that create large void spaces for temporary storage of stormwater while providing sufficient load bearing capacity to allow construction of structures on top of them. Applications are similar to infiltration trenches. Also known as infiltration tanks or vaults.

- Perforated pipe storm sewer systems or Exfiltration trenches: Linear-oriented infiltration trenches installed parallel with conventional storm sewer pipes and catchbasins that receive stormwater from them. May include manholes with perforated risers. Also known as exfiltration storm sewer, percolation drainage, or clean water collector systems.

Inspection and Testing Framework[edit]

Component |

Indicators |

Construction Inspection |

Assumption Inspection |

Routine Operation Inspection |

Verification Inspection |

|---|---|---|---|---|---|

| Contributing Drainage Area | |||||

| CDA condition | x | x | x | x | |

| Inlet | |||||

| Inlet/Flow Spreader Structural Integrity | x | x | x | ||

| Inlet/Flow Spreader Structural Integrity | x | x | x | x | |

| Perimeter | |||||

| BMP dimensions | x | x | x | ||

| Filter Bed | |||||

| Filter bed sediment accumulation | x | x | x | ||

| Underdrain & Monitoring Well | |||||

| Monitoring well condition | x | x | x | x | |

| Sub-drain/Perforated pipe obstruction | x | x | |||

| Outlets | |||||

| Overflow outlet obstruction | x | x | x | x | |

| Control Structure | |||||

| Control structure condition | x | x | x | x | |

| Control structure sediment accumulation | x | x | x | x |

Component |

Indicators |

Construction Inspection |

Assumption Inspection |

Routine Operation Inspection |

Verification Inspection | |

|---|---|---|---|---|---|---|

| Testing Indicators | ||||||

| Sediment accumulation testing | x | x | x | x | ||

| Natural or simulated storm event testing | x | (x) | ||||

| Continuous monitoring | x | (x) | ||||

| Note: (x) denotes indicators to be used for Performance Verification inspections only (i.e., not for Maintenance Verification inspections) | ||||||

Construction Inspection Tasks[edit]

Construction inspections take place during several points in the construction sequence, specific to the type of LID BMP, but at a minimum should be done weekly and include the following:

- During site preparation, prior to BMP excavation and grading to ensure the CDA is stabilized and/or flow diversion devices are in place and confirm that construction materials meet design specifications

- At completion of excavation and grading, prior to backfilling and installation of pipes to ensure depths, slopes and elevations are acceptable

- At completion of installation of geotextile/pipes, prior to completion of backfilling to ensure slopes and elevations are acceptable

- After final grading, prior to surface course installation to ensure depths, slopes and elevations are acceptable

- Prior to hand-off points in the construction sequence when the contractor responsible for the work changes (i.e., hand-offs between the storm sewer servicing, paving, building and landscaping contractors)

- After every large storm event (e.g., 15 mm rainfall depth or greater) to ensure ESCs and pretreatment or flow diversion devices are functioning and adequately maintained. View the table below, which describes critical points during the construction sequence when inspections should be performed prior to proceeding further. You can also download and print the table here

Construction Sequence Step & Timing |

Inspection Item |

Observations* |

|---|---|---|

| Site Preparation - after site clearing and grading, prior to BMP excavation and grading, prior to BMP excavation and grading | Natural heritage system and tree protection areas remain fenced off | |

| ESCs protecting BMP layout area are installed properly | ||

| CDA is stabilized or runoff is diverted around BMP layout area | ||

| BMP layout area has been cleared and is staked/delineated | ||

| Benchmark elevation(s) are established nearby | ||

| Construction materials have been confirmed to meet design specifications | ||

| BMP Excavation and Grading - prior to backfilling and installation of geotextile/pipes | Excavated soil is stockpiled outside the CDA | |

| Excavation location, footprint, depth and slope are acceptable | ||

| Compaction of subsoil where load-bearing portions of the system will be installed is acceptable | ||

| Excavation bottom and sides roughened to reduce smearing and compaction | ||

| BMP Installation – after installation of geotextile/ pipes/structures, prior to completion of backfilling | Installation of structural components (e.g., control manhole, maintenance hatches) is acceptable | |

| Sub-drain trench dams installed correctly (location, elevation) | ||

| Installations of sub-drain pipes (e.g., locations, elevations, slopes) & maintenance access hatches are acceptable |

Routine Maintenance - Key Components and I&M Tasks[edit]

Regular inspections (twice annually, at a minimum) done as part of routine maintenance tasks over the operating phase of the BMP life cycle to determine if maintenance task frequencies are adequate and determine when rehabilitation or further investigations into BMP function are warranted.

Periodic inspections done every 5 years (maintenance verifications) and every 15 years (performance verifications) post-construction over the operating life cycle of the BMP to ensure compliance with the maintenance agreement (e.g., Environmental Compliance Approval permit) conditions, evaluate functional performance and determine when rehabilitation or replacement is necessary.

Requirements of the Ontario Occupational Health and Safety Act regulation for individuals working in confined spaces (O.Reg. 632/05) must be adhered to during any inspection or maintenance work on underground infiltration systems that involves entry into confined spaces (e.g., catchbasins, manholes, access hatches). Individuals working in such environments should be adequately trained on the use and maintenance of the necessary safety equipment and review hazards and safety plans regularly. Further information about Ontario’s Confined Spaces Regulation and Guideline can be accessed here: Confined Spaces Guideline - Ministry of Labour, Immigration, Training and Skills Development.

Table below describes routine maintenance tasks for underground infiltration systems (infiltration chambers, infiltration trenches, bioswales, etc.) organized by BMP component, along with recommended minimum frequencies. It also suggests higher frequencies for certain tasks that may be warranted for BMPs located in highly visible locations or those receiving flow from high traffic (vehicle or pedestrian) areas. Tasks involving removal of trash, debris and sediment and weeding/trimming of vegetation for BMPs in such contexts may need to be done more frequently (i.e., higher standards may be warranted).

| Component | Description | Inspection & Maintenance Tasks | (Pass) Photo Example | (Fail) Photo Example |

|---|---|---|---|---|

| Contributing Drainage Area (CDA) |

Area(s) from which runoff directed to the BMP originates; includes both impervious (i.e., roofs and pavements) and pervious (i.e., landscaped) areas. |

|

||

| Pretreatment |

Devices or features that retain trash, debris and sediment, oil and grease; help to prevent obstructions and clogging of the infiltration area. Examples are eavestrough screens, catch basin inserts (screens, baffles, filters) and sumps, oil and grit separators, geotextile-lined inlets, filters, isolator rows, and water quality forebay units. |

|

Geotextile-lined stone inlet is free of sediment, trash and debris. Stones to slow down and spread out inflowing water remain in place. |

Accumulated sediment, trash and debris in the hydrodynamic (i.e., oil and grit) separator is occupying greater than 50% of its storage capacity. (Photo Source: SWC Canada, 2020)[2] |

| Inlets |

Structures that deliver water to the BMP such as curb-cuts and geotextile-lined inlets or pipes connected to catchbasins, hydrodynamic (oil and grit) separators (HDS), filters, manholes, sub-drains of other features or roof downspouts. |

|

||

| Overflow Outlet |

Structures (e.g., sub-drain/underdrain pipe connected to a manhole, conventional storm sewer pipe, or control manhole with weir wall) that convey flow exceeding the storage capacity to another drainage system or BMP. |

|

||

| Sub-drain |

Comprised of perforated pipe(s) surrounded by gravel and may be wrapped in geotextile filter fabric; installed in the gravel water storage layer or chamber unit openings to collect and convey treated water to an adjacent drainage system or other BMP; may also include a flow restrictor. |

|

||

| Monitoring well |

Perforated standpipe that extends from the bottom of the excavation to just below the pavement surface and contains perforations or slots to allow measurement of subsurface water level; used to track drainage performance over the operating life cycle of the BMP. |

|

Tips to Preserve Basic BMP Function[edit]

- Prohibit stockpiling of soil, sand, compost or unwashed gravel within the CDA and inlets to prevent clogging with sediment.

- For BMPs with sub-drains/underdrains and flow restrictors, pretreatment devices that prevent floating trash and debris from entering the practice should be used to prevent obstruction of the sub-drain pipe/flow restrictor.

- For BMPs equipped with pretreatment that detains floating contaminants (e.g., oil and grease, trash and debris), such as hydrodynamic separators/oil and grit separators or forebays with baffle walls, remove trash and debris first using a bucket strainer. Floating oils and grease should then be removed off the top of the water using a vacuum truck.

- Provide a means of draining infiltration chambers by gravity (e.g., pipe and valve through the control structure weir wall) to make inspection and maintenance work that requires drainage of the BMP (e.g., filter bed and control structure inspection and sediment removal, repairs to control structure) easier to perform.

- To remove accumulated sediment from underdrain pipes and chamber system units, a hydrovac truck equipped with a JetVac nozzle should be employed that uses pressured jets of water to propel itself through the structure while scouring and directing suspending sediments to a collection point. As the nozzle is retrieved, the sediment is flushed into the manhole or catchbasin sump for removal by vacuuming. Selecting an appropriate JetVac nozzle will depend on the structure being cleaned. For chamber system units, fixed nozzles designed for culverts or large diameter pipe cleaning with rear-facing jets are preferable (consult product manufacturer for further guidance).

Rehabilitation & Repair[edit]

Table below provides guidance on rehabilitation and repair work specific to underground infiltration systems organized according to BMP component.

| Component | Problem | Rehabilitation Tasks |

|---|---|---|

| Sub-drain/Underdrain | Sub-drain perforated pipe is obstructed by trash, debris, sediment or roots |

|

| Perforated pipe caps are missing or damaged |

| |

| Isolator Row or Water Quality Forebay Unit |

Sump is ≥ half full or average sediment depth is ≥ 8 cm |

|

| Manhole control structure |

Structure or pipe connection is leaking and impairing the water storage capacity or function of the BMP |

|

Inspection Time Commitments and Costs[edit]

Estimates are based on a typical infiltration trench design that receives roof and road runoff and includes a hydrodynamic separator as pretreatment; estimates for infiltration trenches that receive roof runoff only are described in the Low Impact Development (LID) Stormwater Management Practice Inspection and Maintenance Guide

Estimates of the life cycle costs of inspection and maintenance have been produced using the latest version of the LID Life Cycle Costing Tool for two types of underground infiltration systems: infiltration trenches and infiltration chamber systems to assist stormwater infrastructure planners, designers and asset managers with planning and preparing budgets for potential LID features.

Assumptions for the above costs and the following table below are based on the following:

- For underground infiltration systems it is assumed that no rehabilitation work will be needed to maintain drainage performance at an acceptable level over a 50 year period of operation, given that pretreatment devices are in place upstream and are being adequately maintained. The annual average maintenance cost value represents an average of routine maintenance tasks, as outlined in table, Underground Infiltration Systems: Key Components, Descriptions and Routine I&M Requirements, above. All cost value estimates represent the Net Present Value (NPV) as the calculation takes into account average annual interest (2%) and discount (3%) rates over the evaluation time periods.

- For each type, two design variations have been examined: BMPs designed to receive roof runoff only; and BMPs designed to receive a combination of roof and road runoff. For each system type and design variation, life cycle cost estimates have been calculated for two level-of-service scenarios: the minimum recommended frequency of inspection and maintenance tasks (i.e., Table Visual Indicators Framework - Underground Infiltration Systems and table, Underground Infiltration Systems: Key Components, Descriptions and Routine I&M Requirements, above), and a high frequency scenario to provide an indication of the potential range.

- For all design variations, the CDA is assumed to be composed of a 2,000 m2 roof for the roof runoff only design variation, and a 500 m2 roof and 1,500 m2 impermeable pavement area for the roof and road runoff design. All are sized to retain runoff from a 34 mm rain event and assumed to have a native sub-soil infiltration rate of 34 mm/h. An impervious drainage area to pervious area ratio (I:P ratio) of 20:1 is used to size the BMP footprint area, in accordance with the LID SWM Planning and Design Guide recommendations LID SWM Planning and Design Guide (CVC & TRCA, 2010). The infiltration trench is assumed to be 1.630 m deep, 2.0 m wide and 50.0 m long. The infiltration chamber system is assumed to be 1.067 m deep, 8.0 m wide and 12.5 m long.

- For all design variations, the invert of the overflow outlet pipe is located 1.2 m below the surface to protect against frost. Monitoring wells are provided to facilitate inspections. In the roof runoff only design, there is no pretreatment other than a sump in the control manhole which allows for some settling of coarse sediment and debris. In the roof and road runoff design, pretreatment is provided by a hydrodynamic (i.e., oil and grit) separator for the impermeable pavement portion of the CDA.

- Estimates of the life cycle costs of infiltration trenches and chamber systems in Canadian dollars per unit CDA ($/m2) are presented above. The LID Life Cycle Costing Tool allows users to select what BMP type and design variation applies, and to use the default assumptions to generate planning level cost estimates. Users can also input their own values relating to a site or area, design, unit costs, and inspection and maintenance task frequencies to generate customized cost estimates, specific to a certain project, context or stormwater infrastructure program.

Notes:

- Estimated life cycle costs represent NPV of associated costs in Canadian dollars per square metre of CDA ($/m2).

- Average annual maintenance cost estimates represent NPV of all costs incurred over the time period and do not include rehabilitation costs.

- Life cycle costs are higher for BMPs designed to receive roof and road runoff due to additional costs associated with the hydrodynamic (i.e., oil and grit) separator and associated inspection and routine maintenance.

- Life cycle cost estimates are similar between infiltration trench and infiltration chambers system designs, and predicted to be slightly higher for infiltration trenches compared to chamber systems (construction and maintenance costs).

- Maintenance costs over a 25 year time period for roof runoff only infiltration trenches are estimated to be 30.4% of the original construction cost for the Minimum Recommended Frequency maintenance scenario, and 38.9% for the High Frequency maintenance scenario.

- Maintenance costs over a 25 year time period for roof and road runoff infiltration trenches are estimated to be 67.0% of the original construction cost for the Minimum Recommended Frequency maintenance scenario, and 1.19 times the original construction cost for the High Frequency maintenance scenario.

- Maintenance costs over a 50 year time period for roof runoff only infiltration trenches are estimated to be 58.9% of the original construction cost for the Minimum Recommended Frequency maintenance scenario, and 74.0% for the High Frequency maintenance scenario.

- Maintenance costs over a 50 year time period for roof and road runoff infiltration trenches are estimated to be 1.24 times the original construction cost for the Minimum Recommended Frequency maintenance scenario, and 2.20 times for the High Frequency maintenance scenario.

Inspection Field Data Sheet[edit]

Feel free to download (downward facing arrow on the top righthand side) and print (Pinter emoticon on top right hand side) the following Underground Infiltration Systems Inspection Field Data Form developed by TRCA, STEP and its partners for the Low Impact Development Stormwater Management Practice Inspection and Maintenance Guide[5].

The 4 page document prompts users to fill out details previously mentioned above on this page in other sections about various zones associated with Infiltration Trenches, Infiltration chambers, Exfiltration trench, Soakaways, and other associated features (i.e. inlets, CDA, filter bed, outlets, etc.) and describe why each area is a pass or fail, and if remediate action is required and under what timeframe it would be completed by. Furthermore, the forms prompt the reviewer to determine what type of inspection is being conducted for the feature in question: Construction (C), Routine Operation (RO), Maintenance Verification (MV), or Performance Verification (PV).

References[edit]

- ↑ 1.0 1.1 1.2 1.3 TRCA. 2018. Fact Sheet - Inspection and Maintenance of Stormwater Best Management Practices: Underground Infiltration Systems. https://sustainabletechnologies.ca/app/uploads/2018/02/Underground-Infiltration-Systems-Fact-Sheet.pdf

- ↑ Storm Water Compliance (SWC) Canada Inc. 2020. OIL GRIT SEPARATORS/WATER QUALITY STRUCTURES. Accessed 02 August 2022. https://www.swccanada.com/system-types/oil-grit-separators

- ↑ 3.0 3.1 3.2 TRCA. 2018. Inspection and Maintenance of Stormwater Best Management Practices. Underground Infiltration Systems - Fact Sheet. https://sustainabletechnologies.ca/app/uploads/2018/02/Underground-Infiltration-Systems-Fact-Sheet.pdf

- ↑ TRCA. 2016. Low Impact Development Stormwater Management Practice Inspection and Maintenance Guide. Prepared by the Sustainable Technologies Evaluation Program. Vaughan, Ontario. https://sustainabletechnologies.ca/app/uploads/2016/08/LID-IM-Guide-7.5-Underground-Infiltration-Systems.pdf

- ↑ STEP. 2016. Low Impact Development Stormwater Management Practice Inspection and Maintenance Guide. https://sustainabletechnologies.ca/app/uploads/2016/08/LID-IM-Guide-2016-1.pdf