Inspection and Maintenance: Rainwater Harvesting

Overview[edit]

Rainwater harvesting/cisterns uses storage structures that can be installed either:

- Below-ground;

- Indoors that provide a year-round water source; or,

- Aboveground tanks and rain barrels that can only be used seasonally and must be taken out of service for the winter.

Rainwater cisterns can range in size from about 750 to 40,000 litres+ and may be constructed from fiberglass, plastic, metal or concrete.

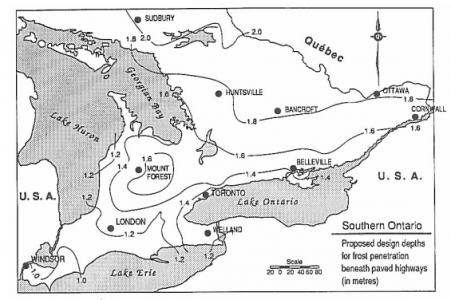

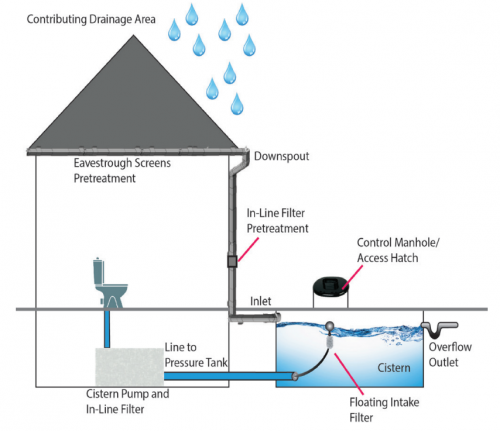

Underground cisterns are most often installed to a depth below the maximum frost penetration depth (generally 1.2 m in Southern Ontario) (Armstrong and Csathy, 1963; Ministry of Transportation, 2013)[2][3] to ensure they can be used year-round. A pump is used to deliver the stored water to the hose bibs or fixtures where it is utilized. Water that is in excess of the storage capacity of the cistern overflows to an adjacent drainage system (e.g., other BMP or municipal storm sewer) via an overflow outlet structure and pipe. Cisterns that are drawn upon for indoor water uses (e.g., toilet flushing) will also feature water level sensors and the means of adding municipal water during extended periods of dry weather or winter when stormwater does not meet the demand (i.e., make-up water supply system). They may also include in-line devices to filter stored cistern water prior to delivery at hose bibs or fixtures.

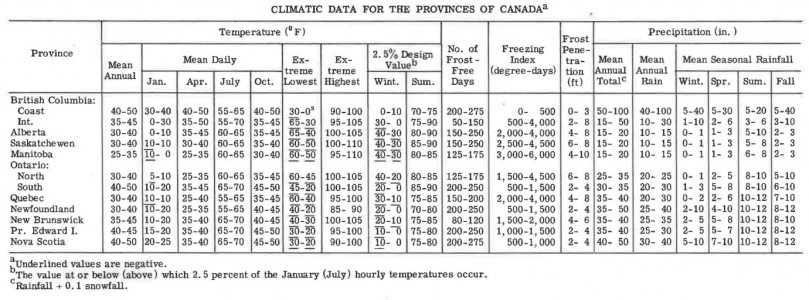

Frost penetration in southern Ontario shown to be 2 - 4 ft. deep (Armstrong and Csathy, 1963)[4].

Design depth showing further detailed frost penetration contour lines for southern Ontario ranging from 1.0 - 2.0m deep (Ministry of Transportation, 2013)[5]

Some of the benefits of green roofs include:

- The ability to reduce the quantity of pollutants and runoff being discharged to municipal storm sewers and receiving waters (i.e., rivers, lakes and wetlands);

- Underground and indoor cisterns can be used year-round and located below parking lots, roads, plazas, parkland, landscaped areas or within buildings themselves.

- Can reduce a large commercial building or residential home's water usage significantly if used for non-potable needs

Key components of Underground Infiltration Systems to pay close attention to are the:

Associated Practices[edit]

- Rain Barrels Rain barrels are an above ground form of rainwater harvesting, typically used in residential settings. The precipitation flows from the roof, to the guttering and down the downspout before being diverted to the rain barrel for storage.

- Downspout disconnection Downspout disconnections are common in many older urban centers. They require that residents retroactively disconnect their downspouts from the municipal sewer system. This is due to older sewer systems being undersized for the combined flow of sanitary waste and stormwater.

- Blue roofs are systems that temporarily capture rainwater using the roof as storage and allow it to evaporate and/or to be used for non-potable requirements (i.e. irrigation, toilet flushing, truck washing) and ultimately offset potable water demands.

Inspection and Testing Framework[edit]

Component |

Indicators |

Construction Inspection |

Assumption Inspection |

Routine Operation Inspection |

Verification Inspection |

|---|---|---|---|---|---|

| Contributing Drainage Area | |||||

| CDA Condition | x | x | x | x | |

| Inlet | |||||

| Inlet/Flow spreader structural integrity | x | x | x | ||

| Inlet/Flow spreader obstruction | x | x | x | x | |

| Pretreatment sediment accumulation | x | x | x | ||

| Perimeter | |||||

| BMP dimensions | x | x | x | ||

| Overflow outlets | |||||

| Overflow outlet obstruction | x | x | x | x | |

| Control structure condition | x | x | x | x | |

| Cistern | |||||

| Cistern structural integrity | x | x | x | x | |

| Cistern sediment accumulation | x | x | x | x |

Component |

Indicators |

Construction Inspection |

Assumption Inspection |

Routine Operation Inspection |

Verification Inspection | |

|---|---|---|---|---|---|---|

| Testing Indicators | ||||||

| Sediment accumulation testing | x | x | x | x | ||

| Cistern pump testing | x | x | (x) | |||

| Note: (x) denotes indicators to be used for Performance Verification inspections only (i.e., not for Maintenance Verification inspections) | ||||||

Construction Inspection Tasks[edit]

Construction inspections take place during several points in the construction sequence, specific to the type of LID BMP, but at a minimum should be done weekly and include the following:

- During site preparation, prior to BMP excavation and grading to ensure that adequate ESCs and flow diversion devices are in place and confirm that construction materials meet design specifications

- At completion of excavation and grading, prior to backfilling and installation of cistern and pipes to ensure depths, slopes and elevations are acceptable

- At completion of installation of cistern and pipes, prior to completion of backfilling to ensure slopes and elevations are acceptable

- Prior to hand-off points in the construction sequence when the contractor responsible for the work changes (i.e., hand-offs between the storm sewer servicing, paving, building and landscaping contractors)

- After every large storm event (e.g., 15 mm rainfall depth or greater) to ensure Erosion Sediment Controls (ESCs) and pretreatment or flow diversion devices are functioning and adequately maintained. View the table below, which describes critical points during the construction sequence when inspections should be performed prior to proceeding further. You can also download and print the table here

Construction Sequence Step & Timing |

Inspection Item |

Observations* |

|---|---|---|

| Site Preparation - after site clearing and grading, prior to BMP excavation and grading | Natural heritage system and tree protection areas remain fenced off | |

| ESCs protecting BMP layout area are installed properly | ||

| CDA is stabilized or runoff is diverted around BMP layout area | ||

| BMP layout area has been cleared and is staked/delineated | ||

| Benchmark elevation(s) are established nearby | ||

| Construction materials have been confirmed to meet design specifications | ||

| BMP Excavation and Grading - prior to backfilling and installation of cistern and conveyance pipes | Excavation location, footprint, depth and slopes are acceptable | |

| Installations of underdrains/sub-drain pipes (location, elevation, slope) are acceptable | ||

| BMP Installation – after installation of pipes/sewers, prior to backfilling | Installation of structural components (i.e., pretreatment devices, inlets, cistern, overflow outlet, pump, make-up water supply and backflow preventer valve, control manhole/ access hatch) are acceptable and functioning |

- ↑ 1.0 1.1 1.2 TRCA. 2018. Fact Sheet - Inspection and Maintenance of Stormwater Best Management Practices: Rainwater Cisterns. https://sustainabletechnologies.ca/app/uploads/2018/02/Rainwater-Cisterns-Fact-Sheet.pdf

- ↑ Armstrong, M. D., & Csathy, T. I. 1963. Frost design practice in Canada-and discussion. Ontario Department of Highways. https://onlinepubs.trb.org/Onlinepubs/hrr/1963/33/33-008.pdf

- ↑ Ministry of Transportation. 2013. Pavement Design and Rehabilitation Manual. Second Edition. IBSN: 978-1-4435-2873-3. Published: March 2013. http://www.bv.transports.gouv.qc.ca/mono/1165561.pdf

- ↑ Armstrong, M. D., & Csathy, T. I. 1963. Frost design practice in Canada-and discussion. Ontario Department of Highways. https://onlinepubs.trb.org/Onlinepubs/hrr/1963/33/33-008.pdf

- ↑ Ministry of Transportation. 2013. Pavement Design and Rehabilitation Manual. Second Edition. IBSN: 978-1-4435-2873-3. Published: March 2013. http://www.bv.transports.gouv.qc.ca/mono/1165561.pdf

- ↑ TRCA. 2019. Low Impact Development Stormwater Inspection and Maintenance Guide. https://sustainabletechnologies.ca/home/urban-runoff-green-infrastructure/low-impact-development/low-impact-development-stormwater-practice-inspection-and-maintenance-guide/