Inspection and Maintenance: Green Roofs

Overview[edit]

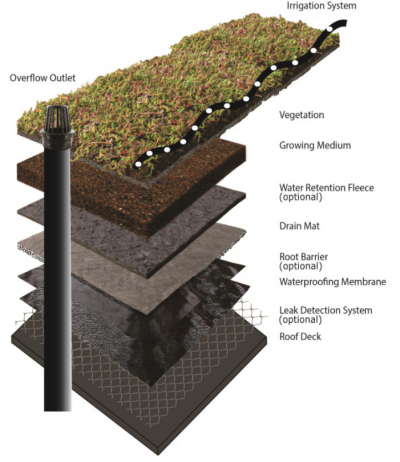

Green roofs are engineered rooftop design features that allow the growth of vegetation on rooftops and have numerous benefits. These LID BMPs can also be referred to as vegetated roofs, rooftop gardens or eco-roofs. A green roof acts like a lawn, meadow or garden by intercepting and absorbing a portion of the rainwater or snowmelt that falls on it. The typical layers of a green roof (in ascending order from the roof surface) include a water-proofing membrane, drainage layer, lightweight growing media layer and the vegetation. Excess water that is not absorbed by the growing media or vegetation is collected by the underlying drainage layer, directed to outlet structures and conveyed via the roof drainage system to another BMP or the municipal storm sewer system. A portion of the water absorbed by green roofs is returned to the atmosphere by evaporation and transpiration by plants. Green roofs are typically designed to retain precipitation from small to medium-sized (e.g., 5 to 25 mm rainfall depth) storm events. Overflow outlets are necessary to safely convey flows from major storm events.

Some of the benefits of green roofs include:

- The ability to reduce the quantity of pollutants and runoff being discharged to municipal storm sewers and receiving waters (i.e., rivers, lakes and wetlands);

- Growing media and plants retain pollutants deposited from the atmosphere and reduce metals and other pollutants from conventional roof materials transported by runoff;

- Improve the energy efficiency of the building due to their insulating properties;

- Reduce the urban heat island effect;

- Can provide food and shelter for pollinators;

- Can provide aesthetic value as attractive landscaped features.

Key components of Underground Infiltration Systems to pay close attention to are the:

Associated Practices[edit]

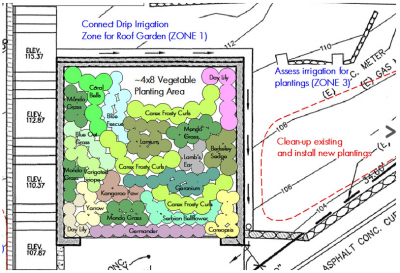

- Intensive green roofs contain greater than 15 cm depth of growing media, can be planted with deeply rooted plants (e.g., shrubs and trees) and can be designed to handle pedestrian traffic.

- Extensive green roofs consist of a thinner growing media layer (15 cm depth or less) and are typically planted with.

- Blue roofs are systems that temporarily capture rainwater using the roof as storage and allow it to evaporate and/or to be used for non-potable requirements (i.e. irrigation, toilet flushing, truck washing) and ultimately offset potable water demands.

Inspection and Testing Framework[edit]

Component |

Indicators |

Construction Inspection |

Assumption Inspection |

Routine Operation Inspection |

Verification Inspection |

|---|---|---|---|---|---|

| Perimeter | |||||

| BMP dimensions | x | x | x | ||

| Growing medium/filter bed | |||||

| Green roof structural integrity | x | x | x | ||

| Standing water | x | x | x | ||

| Filter bed erosion | x | x | |||

| Vegetation | |||||

| Vegetation cover | x | x | x | x | |

| Vegetation condition | x | x | |||

| Vegetation composition | x | x | x | ||

| Overflow outlets | |||||

| Overflow outlet obstruction | x | x | x | x |

Component |

Indicators |

Construction Inspection |

Assumption Inspection |

Routine Operation Inspection |

Verification Inspection | |

|---|---|---|---|---|---|---|

| Testing Indicators | ||||||

| Soil characterization testing | x | x | (x) | |||

| Green roof irrigation system testing | x | x | x | |||

| Green roof leak detection testing | x | x | ||||

| Note: (x) denotes indicators to be used for Performance Verification inspections only (i.e., not for Maintenance Verification inspections) | ||||||

Construction Inspection Tasks[edit]

Construction inspections take place during several points in the construction sequence, specific to the type of LID BMP, but at a minimum should be done weekly and include the following:

- During site preparation, prior to BMP installation to ensure the roof structure is ready for green roof construction work and confirm that BMP layout area matches approved design drawings and that construction materials meet design specifications

- After installation of leak detection system (if applicable) to ensure it was done properly

- At installation of water-proofing membrane, prior to installation of root barrier, drainage layer and overflow outlets to ensure it was done properly and to confirm that slopes are acceptable

- After installation of root barrier, drainage layer (including filter fabric/layer) and overflow outlets, prior to installation of growing medium and plants to ensure it was done properly and confirm that depth and slopes are acceptable

- After installation of growing medium layer and plants to ensure it was done properly and to confirm depth, slopes and elevations at overflow outlets are acceptable; After installation of irrigation system to confirm system is functioning

- Prior to hand-off points in the construction sequence when the contractor responsible for the work changes (i.e., hand-offs between the building and green roof installation contractors)

- After every large storm event (e.g., 15 mm rainfall depth or greater) to ensure roof drainage or flow diversion devices are functioning and adequately maintained. You can also download and print the table here

Construction Sequence Step & Timing |

Inspection Item |

Observations* |

|---|---|---|

| Site Preparation - During site preparation, prior to BMP installation | Ensure the roof structure is ready for green roof construction work | |

| BMP layout area and dimensions match approved design drawings | ||

| CDA is stabilized or runoff is diverted around BMP layout area | ||

| Construction materials have been confirmed to meet design specifications | ||

| Leak detection System - After installation of leak detection system (if applicable), prior to installation of water-proofing membrane | Quality control check leak detection system installation | |

| Water Proofing Membrane – After installation of waterproofing membrane, prior to installation of root barrier, drainage layer and overflow outlets | Quality control check membrane installation | |

| Confirm that slopes conform with approved design drawings | ||

| Root barrier / Drainage layer and Overflow outlets – After installation of root barrier, drainage layer (including filter fabric) and overflow outlets, prior to installation of growing medium layer and plants | Quality control check root barrier and drainage layer installations | |

| Installation of drainage layer (e.g., depth and slope) is acceptable | ||

| Installations of overflow outlets (e.g., elevation and slope) are acceptable | ||

| Filter bed – After installation of filter bed (growing medium layer and plants) | Quality control check installation of any structural components of growing medium layer (if applicable) | |

| Installation of growing medium (e.g., depth, elevations at overflow outlets) is acceptable | ||

| Growing medium is free of ruts, local depressions | ||

| Planting material meets approved planting plan specifications (plant types and quantities) | ||

| Quality control check installation of erosion matting/protection (if applicable) | ||

| Irrigation System - After installation of irrigation system | Confirm installation is acceptable and system is functioning (through testing) |

Routine Maintenance - Key Components and I&M Tasks[edit]

Regular inspections (twice annually, at a minimum) done as part of routine maintenance tasks over the operating phase of the BMP life cycle to determine if maintenance task frequencies are adequate and determine when rehabilitation or further investigations into BMP function are warranted.

The table below describes routine maintenance tasks for green roofs, organized by BMP component, along with recommended minimum frequencies. It also suggests higher frequencies for certain tasks that may be warranted for BMPs located in highly visible or high pedestrian traffic locations or intensive green roofs featuring shrubs, trees and a wider variety of vegetation types. Tasks involving removal of trash, debris and weeding/trimming or replacement of dead plants may need to be done more frequently in such contexts. For further guidance on maintenance of vegetation cover on green roofs, refer to ASTM D2400/E2400M-06 Standard Guide for Selection, Installation and Maintenance of Plants for Green Roof Systems (ASTM International, 2015)[4]

Individuals conducting vegetation maintenance and in particular, weeding (i.e., removal of undesirable vegetation), should be familiar with the species of plants specified in the planting plan and experienced in plant identification and methods of removing/controlling noxious weeds. Key resources on these topics are provided below at the links provided:

- Agriculture and Agri-food Canada’s Weed Info database

- Ontario Ministry of Agriculture, Food and Rural Affairs’ Ontario Weed Gallery

- Ontario Ministry of Agriculture, Food and Rural Affairs’ Noxious Weeds In Ontario list

- Ontario Invasive Plant Council’s Quick Reference Guide to Invasive Plant Species

- Oregon State University Stormwater Solutions, 2013, Field Guide: Maintaining Rain Gardens, Swales and Stormwater Planters, Corvallis, OR.

- Plants of Southern Ontario (book), 2014, by Richard Dickinson and France Royer, Lone Pine Publishing, 528 pgs.

- Weeds of North America (book), 2014, by Richard Dickinson and France Royer, University of Chicago Press, 656 pgs.

| Comnponent | Description | Inspection & Maintenance Tasks | (Pass) Photo Example | (Fail) Photo Example |

|---|---|---|---|---|

| Perimeter |

Separates the green roof from the roof edges and other structures; kept clear of vegetation and natural debris as a fire prevention measure. Parapets or other wind break structures may also be present around the perimeter to help prevent wind scour of growing media. |

annually to biannually. |

||

| Growing medium/filter bed |

Devices or features that retain trash, debris and sediment; help to extend the operating life cycle; examples are eavestrough screens, catch basin inserts and sumps, oil and grit separators, geotextile-lined inlets, gravel trenches, grass filter strips and forebays. |

|

Although permeable pavers are generally considered pretreatment for other BMPs in a treatment train system, using eavestrough screens can act as pretreatment as they don't add to sediment build up and accumulation on the paver surface. (Photo Source: Guertin, 2010)[5] |

Build up of leads, sediment and leaf detritus in an eavestrough downspout disconnection leading to a permeable pavement surface. If not cleaned regularly this can lead to clogged pores between the pavers reducing the infiltration rate where the downspout deposits water onto the feature. (Photo Source: My Gutter Pro, 2021)[6] |

| Inlets |

Structures that deliver water to the BMP (e.g., impermeable pavement edges, pipes from roof downspouts or catchbasins). |

|

Impermeable pavement edges along the edge of the pervious concrete and impermeable asphalt graded so excess sheet flow is infiltrated down through the pores of the infiltration BMP. (Photo Source: Fairfax County, 2014)[7] |

Accumulated sediment, poor grading and vegetation is preventing stormwater from entering the swale. Sediment on the curb cut surface behind of the inlet indicates ponding is also occurring and is depositing water towards the permeable paver surface. |

| Pavement Surface |

The surface of the pavement, including pavers/pavement, joints and edge restraints (e.g., curbs, edging); should not allow water to pond on the surface so any observation or evidence of surface ponding (e.g., sediment caking on the pavement) indicates a drainage problem. |

|

||

| Vegetation |

Applies to grid paver systems only; a mixture of deep rooting perennial grasses or low growing ground covers, tolerant to both wet and dry conditions and salt (if receiving impermeable pavement runoff); roots uptake water and return it to the atmosphere, provide habitat for soil organisms that break down pollutants trapped in the soil and help maintain soil structure and permeability. |

|

||

| Overflow Outlet |

Structures (e.g., catchbasin, curb-cut, swale) that convey flow that exceeds the storage capacity of the BMP to another drainage system (e.g., municipal storm sewer or other BMP). |

|

||

| Sub-drain |

Optional component; perforated pipe(s) surrounded by gravel and may be wrapped in geotextile filter fabric; installed in the base or sub-base gravel layer to collect and convey treated water to an adjacent drainage system or other BMP; may also include a flow restrictor. |

|

||

| Monitoring well |

Perforated standpipe that extends from the bottom of the excavation to just below the pavement surface and contains perforations or slots to allow measurement of subsurface water level; used to track drainage performance over the operating life cycle of the BMP. |

|

||

| Control Structure |

Manhole or catchbasin to which the subdrain outlets that provides access to the underdrain and flow restrictor. Inspect for accessibility, damage and sediment. |

|

- ↑ 1.0 1.1 1.2 TRCA. 2018. Fact Sheet - Inspection and Maintenance of Stormwater Best Management Practices: Green Roofs. https://sustainabletechnologies.ca/app/uploads/2018/02/Green-Roofs-Fact-Sheet.pdf

- ↑ Construction Canada. 2012. Waterproofing considerations for green roofs. Photo source: Detec Systems. 1 March 2012. Accessed August 8 2022. https://www.constructioncanada.net/waterproofing-considerations-for-green-roofs/2/

- ↑ O’Connell Landscape. 2010. FROM THE DRAWING BOARD: MILL VALLEY & CORTE MADERA PLANTINGS. Authored 13 January 2010. Accessed 08 August 2022. https://oclandscape.com/ocblog/from-the-drawing-board-mill-valley-corte-madera-plantings/

- ↑ ASTM International. 2015. Standard Guide for Selection, Installation, and Maintenance of Plants for Green Roof Systems. Designation: E 2400 – 06. http://hydro.engr.scu.edu/files/green_roof/ASTM_E2400-06.pdf

- ↑ Guertin, M. 2010. Simple Screen Gutter Guards Better Than Pro-Installed Systems (and way cheaper). Fine Homebuilding - The Daily Fix. Accessed July 17 2022. https://www.finehomebuilding.com/2010/08/17/simple-screen-gutter-guards-better-than-pro-installed-systems-and-way-cheaper

- ↑ My Gutter Pro. 2021. Clogged Downspout : Causes and Solutions. 10 April 2021. Accessed July 19 2022. https://mygutterpro.com/downspout-clog/

- ↑ Fairfax County. 2014. Protecting our Environment, one Stormwater Practice at a Time - Permeable Pavements. April 2014. Accessed: July 20 2022. https://www.fairfaxcounty.gov/publicworks/sites/publicworks/files/assets/documents/pdf/factsheets/permeable-pavement.pdf