Difference between revisions of "Inspection and Maintenance: Bioretention & Bioswales"

Tag: Manual revert |

|||

| (69 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

[[File:Cover Photo.PNG|thumb|750px|Inspection & Maintenance Guidance of vegetated stormwater best management practices that | [[File:Cover Photo.PNG|thumb|750px|link=https://sustainabletechnologies.ca/app/uploads/2018/02/Bioretention-and-Dry-Swales-Fact-Sheet.pdf|Inspection & Maintenance Guidance of vegetated stormwater best management practices that temporarily store rainwater and snowmelt from roofs, pavement, parking lots, etc. in depressed planting beds, concrete planters or swales (TRCA, 2016)<ref> TRCA. 2016. Fact Sheet - Inspection and Maintenance of Stormwater Best Management Practices: Bioretention. https://sustainabletechnologies.ca/app/uploads/2018/02/Bioretention-and-Dry-Swales-Fact-Sheet.pdf</ref>]] | ||

{{TOClimit|2}} | {{TOClimit|2}} | ||

==Overview== | ==Overview== | ||

[[Bioretention]] treats stormwater by slowing it down, filtering it through soil and plant roots, soaking it into the ground and evaporating it back to the atmosphere. Runoff water is delivered to the practice through [[inlet]]s such as [[curb cuts]], [[Curb cuts: Gallery|spillways]] or other concrete structures, sheet flow from pavement edges, or [[pipes]] connected to [[Pretreatment|catchbasins]] or [[Downspout disconnection|roof downspouts]]. The planting bed and side slopes are typically covered with a mixture of [[plants]], [[mulch]] and [[stone]]. Water in excess of its storage capacity overflows to another BMP or the municipal storm sewer. Filtered water is either infiltrated into the underlying soil to replenish groundwater, or collected by a [[Underdrain|sub-drain]] (i.e., underground perforated pipe) and discharged to the storm sewer system or another BMP. Depending on the permeability of the underlying soil or other constraints, it may be designed with no sub-drain for [[Bioretention: Full infiltration|full infiltration]], with a sub-drain for [[Bioretention: Partial infiltration|partial infiltration]], or with an impermeable liner and sub-drain for a [[Stormwater | [[Bioretention]] treats stormwater by slowing it down, filtering it through soil and plant roots, soaking it into the ground and evaporating it back to the atmosphere. Runoff water is delivered to the practice through [[inlet]]s such as [[curb cuts]], [[Curb cuts: Gallery|spillways]] or other concrete structures, sheet flow from pavement edges, or [[pipes]] connected to [[Pretreatment|catchbasins]] or [[Downspout disconnection|roof downspouts]]. The planting bed and side slopes are typically covered with a mixture of [[plants]], [[mulch]] and [[stone]]. Water in excess of its storage capacity overflows to another BMP or the municipal storm sewer. Filtered water is either infiltrated into the underlying soil to replenish groundwater, or collected by a [[Underdrain|sub-drain]] (i.e., underground perforated pipe) and discharged to the storm sewer system or another BMP. Depending on the permeability of the underlying soil or other constraints, it may be designed with no sub-drain for [[Bioretention: Full infiltration|full infiltration]], with a sub-drain for [[Bioretention: Partial infiltration|partial infiltration]], or with an impermeable liner and sub-drain for a [[Stormwater planters|no infiltration practice]]. The sub-drain pipe may feature a flow restrictor (e.g., orifice cap or valve) for gradually releasing detained water and optimizing the amount drained by infiltration. Key components of bioretention practices for inspection and maintenance described further below. <br> | ||

</br> | |||

==Associated | {{textbox|Key components of [[bioretention]]/[[bioswales]] to pay close attention to are the: | ||

*[[Inlets]] | |||

*[[Filter media|Filter bed surface]] | |||

*[[Overflow|Overflow outlets]]}} | |||

Trash, debris and sediment builds up at these locations and can prevent water from flowing into or out of the practice. | |||

==Associated Practices== | |||

*'''[[Bioretention|Bioretention cell]]''': A flat-bottomed, depressed planting bed containing filter media soil, a gravel water storage layer and optional sub-drain pipe(s); Also known as a rain garden. | *'''[[Bioretention|Bioretention cell]]''': A flat-bottomed, depressed planting bed containing filter media soil, a gravel water storage layer and optional sub-drain pipe(s); Also known as a rain garden. | ||

*'''[[Stormwater planters]]''': A bioretention cell contained within an engineered (e.g., concrete) structure. | *'''[[Stormwater planters]]''': A bioretention cell contained within an engineered (e.g., concrete) structure. | ||

*'''[[Stormwater | *'''[[Stormwater planters|Biofilter]]''': Bioretention cell or swale with an impermeable liner or containment structure and sub-drain. | ||

*'''[[Dry swale]] or [[Bioswale|Bioretention swale]]''': A gently sloping, linear oriented bioretention practice designed to be capable of conveying water across an elevation gradient. Also known as a bioswale or dry swale. | *'''[[Bioswale]] / [[Dry swale]] or [[Bioswale|Bioretention swale]]''': A gently sloping, linear oriented bioretention practice designed to be capable of conveying water across an elevation gradient. Also known as a bioswale or dry swale. | ||

*'''[[Stormwater Tree Trenches]]''': Linear tree planting structures that feature supported impermeable or permeable pavements that promote healthy tree growth while also helping to manage runoff. Consist of subsurface trenches filled with modular structures and growing medium, or structurally engineered soil medium, supporting the overlying sidewalk. | |||

== | ==Inspection and Testing Framework== | ||

[[File:Visual indicator bioretention.PNG|thumb|300px|Example of a visual indicator to be used when assessing the condition of a given LID feature. Here we see excessive sediment accumulation at the [[inlet]]/[[curb cut]] of a bioretention cell. Source: (TRCA, 2016).<ref>STEP. 2016. Low Impact Development Stormwater Management Practice Inspection and Maintenance Guide. https://sustainabletechnologies.ca/app/uploads/2016/08/LID-IM-Guide-2016-1.pdf</ref>.]] | |||

{| class="wikitable" style="width: 900px;" | |||

|+'''Visual Indicators Framework - Bioretention/Swales''' | |||

|- | |||

!<br>'''Component''' | |||

!<br>'''Indicators''' | |||

!<br>'''Construction Inspection''' | |||

!<br>'''Assumption Inspection''' | |||

!<br>'''Routine Operation Inspection''' | |||

!<br>'''Verification Inspection''' | |||

|- | |||

|rowspan="2"|'''[[Bioretention: Sizing|Contributing Drainage Area]]''' | |||

|- | |||

|CDA condition | |||

|x | |||

|x | |||

|x | |||

|x | |||

|- | |||

|rowspan="5"|'''[[Inlets|Inlet]]''' | |||

|- | |||

|Inlet/Flow Spreader Structural Integrity | |||

| | |||

|x | |||

|x | |||

|x | |||

|- | |||

|Inlet/Flow Spreader Structural Integrity | |||

|x | |||

|x | |||

|x | |||

|x | |||

|- | |||

|Pretreatment sediment accumulation | |||

|x | |||

|x | |||

|x | |||

| | |||

|- | |||

|Inlet erosion | |||

| | |||

|x | |||

|x | |||

| | |||

|- | |||

|rowspan="4"|'''Perimeter''' | |||

|- | |||

|BMP dimensions | |||

|x | |||

|x | |||

| | |||

|x | |||

|- | |||

|Side slope erosion | |||

| | |||

|x | |||

|x | |||

| | |||

|- | |||

|Surface ponding area | |||

|x | |||

|x | |||

| | |||

|x | |||

|- | |||

|rowspan="9"|'''[[Bioretention: Filter media|Filter Bed]]''' | |||

|- | |||

|Standing water | |||

| | |||

|x | |||

|x | |||

|x | |||

|- | |||

|Trash | |||

| | |||

|x | |||

|x | |||

| | |||

|- | |||

|Filter bed erosion | |||

| | |||

|x | |||

|x | |||

| | |||

|- | |||

|Mulch depth | |||

|x | |||

|x | |||

|x | |||

|x | |||

|- | |||

|Filter bed sediment accumulation | |||

| | |||

|x | |||

|x | |||

|x | |||

|- | |||

|Surface ponding depth | |||

|x | |||

|x | |||

| | |||

|x | |||

|- | |||

|Filter bed surface sinking | |||

| | |||

|x | |||

|x | |||

|x | |||

|- | |||

|Check dams | |||

|x | |||

|x | |||

|x | |||

|x | |||

|- | |||

|rowspan="4"|'''[[Vegetation|Planting Area]]''' | |||

|- | |||

|Vegetation cover | |||

|x | |||

|x | |||

|x | |||

|x | |||

|- | |||

|Vegetation condition | |||

| | |||

|x | |||

|x | |||

| | |||

|- | |||

|Vegetation composition | |||

|x | |||

|x | |||

|x | |||

| | |||

|- | |||

|rowspan="4"|'''[[Overflow|Outlet]]''' | |||

|- | |||

|Monitoring well condition | |||

|x | |||

|x | |||

|x | |||

|x | |||

|- | |||

|Sub-drain/Perforated pipe obstruction | |||

| | |||

|x | |||

| | |||

|x | |||

|- | |||

|Overflow outlet obstruction | |||

|x | |||

|x | |||

|x | |||

|x | |||

|- | |||

|}<br> | |||

</br> | |||

[[File:Soil testing indicators.PNG|thumb|300px|The image above shows a manual soil corer, a split soil core sampler kit which preserves the soil sample for further testing (i.e., bulk density) and acrylic core sample tubes. All examples of tools to be use for soil characterization testing. Source: (TRCA, 2016).<ref>STEP. 2016. Low Impact Development Stormwater Management Practice Inspection and Maintenance Guide. https://sustainabletechnologies.ca/app/uploads/2016/08/LID-IM-Guide-2016-1.pdf</ref>.]] | |||

{| class="wikitable" style="width: 900px;" | |||

|+'''Testing Indicators Framework - Bioretention/Swales''' | |||

|- | |||

!<br>'''Component''' | |||

!<br>'''Indicators''' | |||

!<br>'''Construction Inspection''' | |||

!<br>'''Assumption Inspection''' | |||

!<br>'''Routine Operation Inspection''' | |||

!<br>'''Verification Inspection''' | |||

|- | |||

|rowspan="6"|'''Testing Indicators''' | |||

|- | |||

|Soil characterization testing | |||

|x | |||

|x | |||

| | |||

|(x) | |||

|- | |||

|Sediment accumulation testing | |||

|x | |||

|x | |||

|x | |||

|x | |||

|- | |||

|Surface infiltration rate testing | |||

| | |||

|x | |||

| | |||

|(x) | |||

|- | |||

|Natural or simulated storm event testing | |||

| | |||

|x | |||

| | |||

|(x) | |||

|- | |||

|Continuous monitoring | |||

| | |||

|x | |||

| | |||

|(x) | |||

|- | |||

|colspan="7" style="text-align: center;" |'''<u><span title=>Note:''' (x) denotes indicators to be used for Performance Verification inspections only (i.e., not for Maintenance Verification inspections) </span></u> | |||

|- | |||

|} | |||

==Construction Inspection Tasks== | ==Construction Inspection Tasks== | ||

[[File:LID-IM small.jpg|thumb|400px|Performance Inspection of a Rain garden. [https://sustainabletechnologies.ca/home/urban-runoff-green-infrastructure/low-impact-development/low-impact-development-stormwater-practice-inspection-and-maintenance-guide/ Photo source: TRCA].<ref>TRCA. 2019. Low Impact Development Stormwater Inspection and Maintenance Guide. https://sustainabletechnologies.ca/home/urban-runoff-green-infrastructure/low-impact-development/low-impact-development-stormwater-practice-inspection-and-maintenance-guide/</ref>]] | |||

Construction inspections take place during several points in the construction sequence, specific to the type of LID BMP, but at a minimum should be done '''weekly''' and include the following: | Construction inspections take place during several points in the construction sequence, specific to the type of LID BMP, but at a minimum should be done '''weekly''' and include the following: | ||

# During site preparation, prior to BMP excavation and grading to ensure the CDA is stabilized or that adequate ESCs or flow diversion devices are in place and confirm that construction materials meet design specifications | # During site preparation, prior to BMP excavation and grading to ensure the CDA is stabilized or that adequate ESCs or flow diversion devices are in place and confirm that construction materials meet design specifications | ||

| Line 26: | Line 234: | ||

# After final grading, prior to planting to ensure depths, slopes and elevations are acceptable; | # After final grading, prior to planting to ensure depths, slopes and elevations are acceptable; | ||

# Prior to hand-off points in the construction sequence when the contractor responsible for the work changes (i.e., hand-offs between the storm sewer servicing, paving, building and landscaping contractors) | # Prior to hand-off points in the construction sequence when the contractor responsible for the work changes (i.e., hand-offs between the storm sewer servicing, paving, building and landscaping contractors) | ||

# After every large storm event (e.g., 15 mm rainfall depth or greater) to ensure [https://sustainabletechnologies.ca/app/uploads/2020/01/ESC-Guide-for-Urban-Construction_FINAL.pdf Erosion Sediment Controls (ESCs)] and pretreatment or flow diversion devices are functioning and adequately maintained. View the table below, which describes critical points during the construction sequence when inspections should be performed prior to proceeding further. | # After every large storm event (e.g., 15 mm rainfall depth or greater) to ensure [https://sustainabletechnologies.ca/app/uploads/2020/01/ESC-Guide-for-Urban-Construction_FINAL.pdf Erosion Sediment Controls (ESCs)] and pretreatment or flow diversion devices are functioning and adequately maintained. View the table below, which describes critical points during the construction sequence when inspections should be performed prior to proceeding further. You can also download and print the table [https://wikidev.sustainabletechnologies.ca/images/7/7f/Construction_Inspection.pdf '''here''']<br> | ||

{| class="wikitable" style="width: 1000px;" | |||

{|class="wikitable" | |||

|+'''Bioretention/Swales: Construction Inspections''' | |+'''Bioretention/Swales: Construction Inspections''' | ||

|- | |- | ||

!'''Construction Sequence Step & Timing''' | !<br>'''Construction Sequence Step & Timing''' | ||

!'''Inspection Item''' | !<br>'''Inspection Item'''<br> | ||

!'''Observations*''' | !<br>'''<u><span title="Note for Observation Column: S = Satisfactory; U= Unsatisfactory; NA = Not Applicable ">Observations*</u>'''<br> | ||

|- | |- | ||

|'''Site Preparation''' - after site clearing and grading, prior to BMP excavation and grading | |rowspan="6"|'''Site Preparation''' - after site clearing and grading, prior to BMP excavation and grading | ||

|Natural heritage system and tree protection areas remain fenced off | |||

| | | | ||

|- | |- | ||

ESCs protecting BMP layout area are installed properly | |ESCs protecting BMP layout area are installed properly | ||

| | |||

|- | |- | ||

CDA is stabilized or runoff is diverted around BMP layout area | |CDA is stabilized or runoff is diverted around BMP layout area | ||

| | |||

|- | |- | ||

BMP layout area has been cleared and is staked/delineated | |BMP layout area has been cleared and is staked/delineated | ||

| | |||

|- | |- | ||

Benchmark elevation(s) are established nearby | |Benchmark elevation(s) are established nearby | ||

| | |||

|- | |- | ||

Construction materials have been confirmed to meet design specifications | |Construction materials have been confirmed to meet design specifications | ||

| | |||

|- | |||

|rowspan="4"|'''BMP Excavation and Grading''' - prior to installation of pipes/sewers and backfilling | |||

|Excavation location, footprint, depth and slopes are acceptable | |||

| | |||

|- | |||

|Excavated soil is stockpiled outside the CDA | |||

| | |||

|- | |||

|Embankments/berms (elevations, slopes, compaction) are acceptable | |||

| | |||

|- | |||

|Excavation bottom and sides roughened to reduce smearing and compaction | |||

| | |||

|- | |||

|rowspan="4"|'''BMP Installation''' – after installation of pipes/sewers, prior to backfilling | |||

|Structural components (e.g., foundation, walls) installed according to plans, if applicable | |||

| | |||

|- | |||

|Impermeable liner installed correctly, if applicable | |||

| | | | ||

|- | |- | ||

| | |Installations of sub-drain pipes (e.g., locations, elevations, slopes), standpipes/monitoring wells are acceptable | ||

| | | | ||

|- | |- | ||

| | |Sub-drain trench dams installed correctly (location, elevation) | ||

| | | | ||

|- | |||

|rowspan="4"|'''Landscaping''' – after final grading, prior to planting | |||

|Filter bed depth and surface elevations at inlets are acceptable | |||

| | | | ||

|- | |- | ||

| | |Maximum surface ponding depth is acceptable | ||

| | | | ||

|- | |||

|Filter bed is free of ruts, local depressions and not overly compacted | |||

| | | | ||

* | |- | ||

|Planting material meets approved planting plan specifications (plant types and quantities) | |||

|- | |||

|colspan="3" style="text-align: center;" |'''<u><span title=>Note:''' for Observation Column: S = Satisfactory; U = Unsatisfactory; NA = Not Applicable*</span></u> | |||

|- | |||

|} | |} | ||

==Routine Maintenance - Key Components and I&M Tasks== | ==Routine Maintenance - Key Components and I&M Tasks== | ||

{|class="wikitable" | Regular inspections (twice annually, at a minimum) done as part of routine maintenance tasks over the operating phase of the BMP life cycle to determine if maintenance task frequencies are adequate and determine when rehabilitation or further investigations into BMP function are warranted. | ||

|+'''Bioretention/Swales: Key Components, Descriptions and Routine I&M | |||

Table below describes routine maintenance tasks for [[bioretention]] practices, organized by BMP component, along with recommended minimum frequencies. It also suggests higher frequencies for certain tasks that may be warranted for BMPs located in highly visible locations or those receiving flow from high traffic areas (vehicle or pedestrian). Tasks involving removal of trash, debris and sediment and weeding/trimming of [[vegetation]] for BMPs in such contexts may need to be done more frequently (i.e., higher standards may be warranted). | |||

Individuals conducting [[vegetation]] maintenance and in particular, weeding (i.e., removal of undesirable vegetation), should be familiar with the species of [[Plant lists|plants]] specified in the planting plan and experienced in plant identification and methods of removing/controlling noxious weeds. Key resources on these topics are provided below at the links provided: | |||

*[http://www.weedinfo.ca/en/ Agriculture and Agri-food Canada’s Weed Info database] | |||

*[http://www.omafra.gov.on.ca/english/crops/facts/ontweeds/weedgal.htm Ontario Ministry of Agriculture, Food and Rural Affairs’ Ontario Weed Gallery] | |||

*[http://www.omafra.gov.on.ca/english/crops/facts/noxious_weeds.htm Ontario Ministry of Agriculture, Food and Rural Affairs’ Noxious Weeds In Ontario list] | |||

*[https://www.ontarioinvasiveplants.ca/wp-content/uploads/2016/07/QRG_FINAL.pdf Ontario Invasive Plant Council’s Quick Reference Guide to Invasive Plant Species] | |||

*[https://wrrc.arizona.edu/sites/wrrc.arizona.edu/files/OSU_Field%20Guide%20-%20Maintaining%20Rain%20Gardens%2C%20Swales%2C%20and%20Stormwater%20Planters.pdf Oregon State University Stormwater Solutions, 2013, Field Guide: Maintaining Rain Gardens, Swales and Stormwater Planters, Corvallis, OR.] | |||

*[https://lonepinebooks.com/product/plants-of-southern-ontario-2/ Plants of Southern Ontario (book), 2014, by Richard Dickinson and France Royer, Lone Pine Publishing, 528 pgs.] | |||

*[http://www.agrifs.ir/sites/default/files/Weeds%20of%20North%20America%20%7BRichard%20Dickinson%7D%20%5B9780226076447%5D%20%282014%29_2.pdf Weeds of North America (book), 2014, by Richard Dickinson and France Royer, University of Chicago Press, 656 pgs.] | |||

{|class="wikitable" style="width: 1280px" | |||

|+'''Bioretention/Swales: Key Components, Descriptions and Routine I&M Requirements''' | |||

|- | |- | ||

! | !style="width: 500px"|Comnponent | ||

!Description | !style="width: 1500px"|Description | ||

!Inspection & Maintenance Tasks | !style="width: 1500px"|Inspection & Maintenance Tasks | ||

!style="width: 500px"|<span style="color:green">('''Pass''')</span> Photo Example | |||

!style="width: 550px"|<span style="color:red">('''Fail''')</span> Photo Example | |||

|- | |- | ||

|'''[[Bioretention: Sizing|Contributing Drainage Area (CDA)]]''' | |'''[[Bioretention: Sizing|Contributing Drainage Area (CDA)]]''' | ||

| Line 82: | Line 332: | ||

*Remove trash, debris and sediment from pavements (biannually to quarterly) and eavestroughs (annually); | *Remove trash, debris and sediment from pavements (biannually to quarterly) and eavestroughs (annually); | ||

*Replant or seed bare soil areas as needed. | *Replant or seed bare soil areas as needed. | ||

|[[File:Pass.PNG|300px|thumb|center|CDA has not changed in size or land cover. Sediment, trash or debris is not accumulating and point sources of contaminants are not visible.]] | |||

|[[File:Fail bio.PNG|280px|thumb|center|Size of the CDA has changed from design assumptions. A point source for contaminants is visible (i.e. lack of sediment controls on adjacent construction site). (Photo Source: North Carolina Cooperative Extension)]] | |||

|- | |- | ||

|'''[[Pretreatment]]''' | |'''[[Pretreatment]]''' | ||

| Line 89: | Line 341: | ||

*Remove trash, debris and sediment annually to biannually or when the device sump is half full; | *Remove trash, debris and sediment annually to biannually or when the device sump is half full; | ||

*Measure sediment depth or volume during each cleaning, or annually to estimate accumulation rate and optimize frequency of maintenance | *Measure sediment depth or volume during each cleaning, or annually to estimate accumulation rate and optimize frequency of maintenance | ||

|[[File:Pretreatment pass bio.PNG|310px|thumb|center|[[Forebay]] is free of sediment, trash and debris and recently maintained. The large stones in the feature are used to slow down and spread out inflowing water into the feature and they remain well arranged and in place.]] | |||

|[[File:Pretreatment fail bio.PNG|290px|thumb|center|An erosion gully occurring where bare soil is starting to become visible on the [[Vegetated filter strips|grass filter strip]] pretreatment feature at the inlet, thus indicating it is not effectively slowing and spreading out the inflow of stormwater to the BMP.]] | |||

|- | |- | ||

|'''[[Inlets]]''' | |'''[[Inlets]]''' | ||

| Line 98: | Line 352: | ||

*Measure sediment depth or volume during each cleaning or annually to estimate accumulation rate and optimize frequency of maintenance; | *Measure sediment depth or volume during each cleaning or annually to estimate accumulation rate and optimize frequency of maintenance; | ||

*Remove woody [[vegetation]] from filter bed at [[inlets]] annually. | *Remove woody [[vegetation]] from filter bed at [[inlets]] annually. | ||

|[[File:Inlets bio pass.PNG|285px|thumb|center|There is no evidence of damage or displacement of the inlet structure that would prevent runoff from freely entering the BMP.]] | |||

|[[File:Inlets bio fail.PNG|300px|thumb|center|Accumulated sediment and vegetation is preventing stormwater from entering the BMP. Sediment on the pavement surface in front of the inlet indicates ponding is also occurring]] | |||

|- | |- | ||

|'''Perimeter''' | |'''Perimeter''' | ||

| Line 105: | Line 361: | ||

*Confirm the surface ponding footprint area dimensions are within ±10% of the design and that maximum surface ponding depth meets design specifications; | *Confirm the surface ponding footprint area dimensions are within ±10% of the design and that maximum surface ponding depth meets design specifications; | ||

*Check for side slope erosion or damage that compromises water storage capacity | *Check for side slope erosion or damage that compromises water storage capacity | ||

|[[File:Perimeter bio pass.PNG|305px|thumb|center|The footprint area of the bioretention cell does not significantly deviate from the final design and should not negatively affect its stormwater management treatment performance.]] | |||

|[[File:Perimeter bio fail.PNG|300px|thumb|center|The footprint area of the BMP is significantly smaller than what was specified in the final design of this example and differ greater than the recommended SWM criteria requirements (>10%).]] | |||

|- | |- | ||

|'''[[Bioretention: Construction checklist|Filter Bed]]''' | |'''[[Bioretention: Construction checklist|Filter Bed]]''' | ||

| Line 116: | Line 374: | ||

*Repair sunken areas when ≥ 10 cm deep and barren/eroded areas when ≥ 30 cm long; | *Repair sunken areas when ≥ 10 cm deep and barren/eroded areas when ≥ 30 cm long; | ||

*Remove sediment when > 5 cm deep or time to drain water ponded on the surface exceeds 48 hours. | *Remove sediment when > 5 cm deep or time to drain water ponded on the surface exceeds 48 hours. | ||

|[[File:Filter bed bio pass.PNG|295px|thumb|center|There are no erosion gullies or bare soil areas on the filter bed surface and mulch cover remains in place.]] | |||

|[[File:Filter bed bio fail.PNG|300px|thumb|center|Erosion gullies and bare soil areas are present on the filter bed surface, indicating that concentrated flow occurs regularly into the BMP feature. (Photo Source: CVC).]] | |||

|- | |- | ||

|'''[[Vegetation]]''' | |'''[[Vegetation]]''' | ||

| Line 126: | Line 386: | ||

*Replace dead plantings annually to achieve 80% cover by the third growing season; | *Replace dead plantings annually to achieve 80% cover by the third growing season; | ||

*Do not apply chemical fertilizers. | *Do not apply chemical fertilizers. | ||

|[[File:Vegetation bio pass.PNG|315px|thumb|center|The planted portion of the bioretention cell is completely covered with dense, attractive vegetation which helps to maintain its stormwater treatment function and aesthetic value.]] | |||

|[[File:Vegetation bio fail .PNG|290px|thumb|center|A larger portion of the bioretention cell has no vegetation cover which reduces its aesthetic value and could be negatively affecting its stormwater treatment function. Much less than 80% of the planting area is covered by living vegetation requiring immediate maintenance and reseeding.]] | |||

|- | |- | ||

|'''[[Overflow|Overflow Outlet]]''' | |'''[[Overflow|Overflow Outlet]]''' | ||

| Line 133: | Line 395: | ||

*Keep free of obstructions; | *Keep free of obstructions; | ||

*Remove trash, debris and sediment biannually to quarterly. | *Remove trash, debris and sediment biannually to quarterly. | ||

|[[File:Overflow bio pass.PNG|320px|thumb|center|The overflow outlet is free of damage and obstruction and functions as originally designed.]] | |||

|[[File:Overflow bio fail.PNG|280px|thumb|center|The overflow outlet is partially obstructed with trash and debris which reduces its capacity to safely convey excess water from the BMP, likely due to excess ponding thus obstructing outflow and impairing overall drainage function of the BMP.]] | |||

|- | |- | ||

|'''[[Underdrain|Sub-drain]]''' | |'''[[Underdrain|Sub-drain]]''' | ||

| Line 141: | Line 405: | ||

*Keep pipe and flow restrictor free of obstructions by flushing annually; | *Keep pipe and flow restrictor free of obstructions by flushing annually; | ||

*Inspect flow restrictor frequently (e.g., biannually to quarterly). | *Inspect flow restrictor frequently (e.g., biannually to quarterly). | ||

|[[File:Underdrain bio pass.PNG|310px|thumb|center|The perforated sub-drain pipe is not obstructed by sediment, debris or roots and shows no signs of damage.]] | |||

|[[File:Underdrain bio fail.PNG|300px|thumb|center|Roots have penetrated the underdrain/sub-drain pipe and are substantially reducing its conveyance capacity. Structural damage, sediment/debris clogs or vegetation roots are visible and are reducing the conveyance capacity of the pipe by one third (33%) or more. (Photo Source: Pipelining Denver)]] | |||

|- | |- | ||

|'''[[Monitoring well]]''' | |'''[[Monitoring well]]''' | ||

| Line 147: | Line 413: | ||

| | | | ||

*[[Wells|Standpipes]] should be securely capped on both ends and remain undamaged. | *[[Wells|Standpipes]] should be securely capped on both ends and remain undamaged. | ||

|[[File:MonitoringWell bio pass.PNG|340px|thumb|center|The well is undamaged and accessible and the cap is in place and secured to prevent unauthorized access.]] | |||

|[[File:MonitoringWell bio fail.PNG|300px|thumb|center|The well standpipe has been damaged by snow plowing, which impairs its use for monitoring and is a safety hazard. With the cap unable to be secured unauthorized access can also occur.]] | |||

|} | |} | ||

==Tips to Preserve Basic BMP Function== | |||

*Maintain grading of the filter bed (or [[Vegetated filter strips|grass filter strip]] if present) at [[curb cut]] [[inlets]] so at least 5 cm of the back of the curb is visible through regular sediment removal and regrading. | |||

*To avoid over-compaction of the [[Bioretention: Filter media|filter media soil]], any maintenance tasks involving vehicle or foot traffic on the filter bed should not be performed during wet weather. | |||

*For bioretention with sod (i.e., [[Turf|turf grass]]) as [[vegetation]] cover, maintain with a push mower or the lightest mulching ride mower available and core aerate and dethatch annually in the spring to help maintain permeability. | |||

*Pruning of mature [[trees]] should be performed under the guidance of a Certified Arborist. | |||

*Woody [[vegetation]] should not be planted or allowed to become established where snow will be piled/stored during [[Winter]]. | |||

*Removal of sediment from the filter bed surface should be done with rake and shovel, or vacuum equipment to minimize plant disturbance. If a small excavator is to be used, keep it off the BMP footprint to avoid damage to side slopes/embankments and over-compaction of the [[filter media]]. | |||

==Rehabilitation & Repair== | ==Rehabilitation & Repair== | ||

{|class="wikitable" | |||

Table below provides guidance on rehabilitation and repair work specific to bioretention and dry swales organized according to BMP component. | |||

{|{| class="wikitable" style="width: 1000px;" | |||

|+'''Bioretention/Swales: Key Components, Typical Issues and Rehabilitation Requirements''' | |+'''Bioretention/Swales: Key Components, Typical Issues and Rehabilitation Requirements''' | ||

|- | |- | ||

| Line 188: | Line 467: | ||

*Schedule hydro-vac truck or drain-snaking service to clear the obstruction. | *Schedule hydro-vac truck or drain-snaking service to clear the obstruction. | ||

|} | |} | ||

[[File:Sediment removal.PNG|500px]] | |||

<br> | |||

Technician conducting sediment removal to ensure infiltration rates for the<br> | |||

practice are able to maintain > 25 mm/h. [https://sustainabletechnologies.ca/app/uploads/2018/02/Bioretention-and-Dry-Swales-Fact-Sheet.pdf Photo Source: TRCA, 2018]<ref>TRCA. 2018. Inspection and Maintenance of Stormwater Best Management Practices - Bioretention. Fact Sheet. https://sustainabletechnologies.ca/app/uploads/2018/02/Bioretention-and-Dry-Swales-Fact-Sheet.pdf</ref> | |||

==Inspection Time Commitments and Costs== | |||

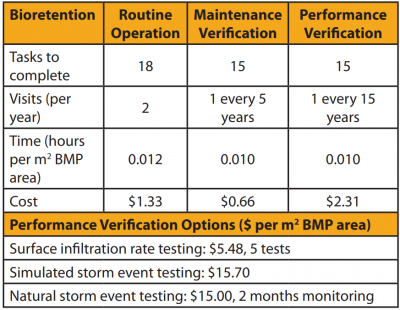

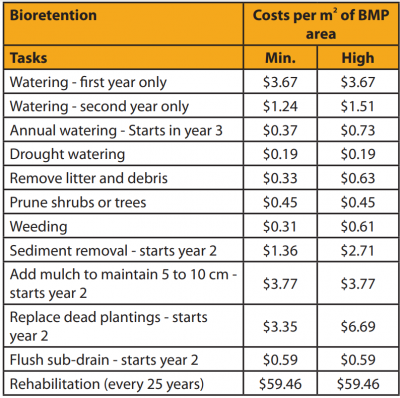

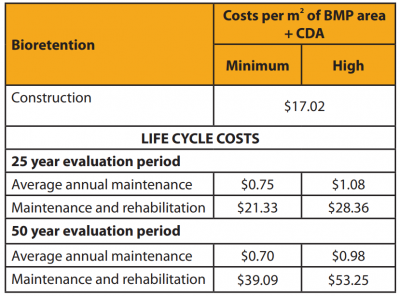

Estimates are based on a typical partial infiltration bioretention design (i.e., includes a sub-drain); estimates for other designs (i.e., full infiltration and no-infiltration) can be found in the [https://sustainabletechnologies.ca/app/uploads/2016/08/LID-IM-Guide-7.1-Bioretention-and-Dry-Swales.pdf Low Impact Development (LID) Stormwater Management Practice Inspection and Maintenance Guide]<br> | |||

</br> | |||

[[File:Time commit cost.PNG|thumb|left|400px|General time commitments and costs for inspection of bioretention and dry swale features with partial infiltration (in 2016 $ figures).<ref>TRCA. 2018. Inspection and Maintenance of Stormwater Best Management Practices. Bioretention - Fact Sheet. https://sustainabletechnologies.ca/app/uploads/2018/02/Bioretention-and-Dry-Swales-Fact-Sheet.pdf</ref>]] | |||

[[File:Cost per maintenance task.PNG|thumb|400px|Per-task cost estimates for maintenance and rehabilitation of a partial infiltration bioretention feature (in 2016 $ figures).<ref>TRCA. 2018. Inspection and Maintenance of Stormwater Best Management Practices. Bioretention - Fact Sheet. https://sustainabletechnologies.ca/app/uploads/2018/02/Bioretention-and-Dry-Swales-Fact-Sheet.pdf</ref>]] | |||

[[File:Life cycle costs.PNG|thumb|center|400px|Construction and life cycle cost estimates for bioretention and dry swale features with partial infiltration (in 2016 $ figures).<ref>TRCA. 2018. Inspection and Maintenance of Stormwater Best Management Practices. Bioretention - Fact Sheet. https://sustainabletechnologies.ca/app/uploads/2018/02/Bioretention-and-Dry-Swales-Fact-Sheet.pdf</ref>]]<br> | |||

</br> | |||

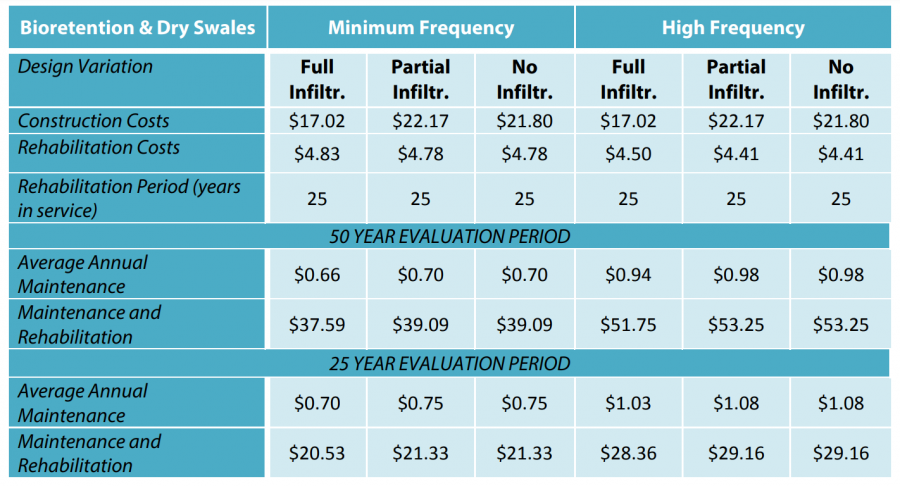

Estimates of the life cycle costs of inspection and maintenance have been produced using the latest version of the [[Cost analysis resources|LID Life Cycle Costing Tool]] for three design variations (full infiltration, partial infiltration and no infiltration) to assist stormwater infrastructure planners, designers and asset managers with planning and preparing budgets for potential LID features. | |||

Assumptions for the above costs and the following table below are based on the following: | |||

*Capital costs included within the category of construction include those related to site assessment, and conceptual and detailed design related tasks such as borehole analysis and soil testing. All material, delivery, labour, equipment (rental, operation, operator), hauling and disposal costs are accounted for within the construction costs of the facility. Standard union costs were derived from the RSMeans database in 2010 and have been adjusted for 5 year inflation of 8.79% (2010 to June, 2015). | |||

**Costs include overhead and inflation to represent contractor pricing. It was assumed the practice is part of a new development (i.e., not a retrofit), thereby excluding (de)mobilization costs unless a particular piece of equipment would not normally have been present at the site. Additionally, it was assumed that excavated soil associated with construction of the BMP would be reused elsewhere on site. Overhead costs were presumed to consist of construction management (4.5%), design (2.5%), small tools (0.5%), clean up (0.3%) and other (2.2%). | |||

*For maintenance frequencies and requirements and the life span of each practice are based on both literature and practical experience. Life cycle and associated maintenance costs are evaluated over a 50 year timeframe, which is the typical period over which infrastructure decisions are made. | |||

*For [[bioretention]], it is assumed that some rehabilitation (e.g., rehabilitative maintenance) work will be needed on the filter bed surface once the BMP reaches 25 and 50 years of age in order to maintain functional drainage performance at an acceptable level. Included in the rehabilitation costs are (de)mobilization costs, as equipment would not have been present on site. Design costs were not included in the rehabilitation as it was assumed that the original LID practice design would be used to inform this work. The annual average maintenance cost does not include rehabilitation costs and therefore represents an average of routine maintenance tasks, as outlined in the Table under section, [[Inspection and Maintenance: Bioretention & Dry Swales#Routine Maintenance - Key Components and I&M Tasks|Routine Maintenance - Key Components and I&M Tasks]] above. All cost value estimates represent the net present value (NPV) as the calculation takes into account average annual interest (2%) and discount (3%) rates over the evaluation time periods. | |||

*For all bioretention design variations, the CDA has been defined as a 2,000 m2 impervious pavement area plus the footprint area of a bioretention cell that is 133 m2 in size, as per design recommendations. The impervious area to pervious area ratio (I:P ratio) used to size the BMP footprint is 15:1, which is the maximum ratio recommended in the LID SWM Planning and Design Guide (CVC & TRCA, 2010)<ref>CVC and TRCA. 2010. Low Impact Development Stormwater Management Planning and Design Guide. Version 1.0. https://cvc.ca/wp-content/uploads/2014/04/LID-SWM-Guide-v1.0_2010_1_no-appendices.pdf</ref>. It is assumed that water drains to the cell through curb inlets spaced 6 m apart with | |||

stone cover on the filter bed at the inlets to dissipate the energy of the flowing water. | |||

*While orientation (i.e., cell versus swale) and choice of components (e.g., inlet/outlet structures etc.) can vary widely, design variations for bioretention practices can be broken down into three main categories. They can be designed to drain through infiltration into the underlying subsoil alone (i.e., Full Infiltration design, no sub-drain), through the combination of a sub-drain and infiltration into the underlying subsoil (i.e., Partial Infiltration design, with a sub-drain), or through a sub-drain alone (i.e., No Infiltration or “filtration only” design, with a sub-drain and impermeable liner). For Full Infiltration systems, an overflow is provided for storms up to 37 mm based on a subsoil infiltration rate of 20 mm/hour. Two standpipe wells are part of the design (one subdrain inspection/flushing port at the upstream end and one sub-surface water storage reservoir monitoring well at the downstream end). Partial Infiltration systems have a sub-surface water storage reservoir with a perforated pipe sub-drain within it. The depth of the reservoir is sized to store flow from a 25 mm rain event over the CDA based on native soil infiltration rate of 10 mm/hour. The No Infiltration system includes an impermeable liner between the base and sides of the BMP and surrounding native sub-soil, to prevent infiltration. | |||

*Estimates of the life cycle costs of bioretention and dry swales in Canadian dollars per unit CDA ($/m2) are presented in the table below. [[Cost analysis resources|LID Life Cycle Costing Tool]] allows users to select what BMP type and design variation applies, and to use the default assumptions to generate planning level cost estimates. | |||

**Users can also input their own values relating to a site or area, design, unit costs, and inspection and maintenance task frequencies to generate customized cost estimates, specific to a certain project, context or stormwater infrastructure program. | |||

**For all BMP design variations and maintenance scenarios, it is assumed that rehabilitation of part or all of the filter bed surface will be necessary once the BMP reaches 25 and 50 years of age to maintain acceptable surface drainage performance (e.g., surface ponding drainage time). Filter bed rehabilitation for bioretention and dry swales is assumed to typically involve the tasks outlined under section, [[Inspection and Maintenance: Bioretention & Dry Swales#Routine Maintenance - Key Components and I&M Tasks|Routine Maintenance - Key Components and I&M Tasks]] above.<br> | |||

</br> | |||

[[File:Life cycle cost for all variations.PNG|thumb|center|900px|Life cycle cost estimates for all variation types of [[bioretention]] and [[Dry swale|dry swales]] under minimum and high frequency scenarios (in 2016 $ figures).<ref>TRCA. 2018. Inspection and Maintenance of Stormwater Best Management Practices. Bioretention - Fact Sheet. https://sustainabletechnologies.ca/app/uploads/2018/02/Bioretention-and-Dry-Swales-Fact-Sheet.pdf</ref>]] | |||

'''Notes:''' | |||

#Estimated life cycle costs represent NPV of associated costs in Canadian dollars per squaremetre of CDA ($/m2). | |||

#Average annual maintenance cost estimates represent NPV of all costs incurred over the time period and do not include rehabilitation costs. | |||

#Rehabilitation cost estimates represent NPV of all costs related to repair work assumed to occur every 25 years, including those associated with inspection and maintenance over a two (2) year establishment period for the plantings. | |||

#Full Infiltration design life cycle costs are lower than Partial and No Infiltration designs due to the absence of a sub-drain to construct, inspect and routinely flush. | |||

#Rehabilitation costs for Full Infiltration designs are estimated to be 26.4 to 28.4% of the original construction costs for High and Minimum Recommended Frequency maintenance program scenarios, respectively. | |||

#Rehabilitation costs for Partial Infiltration designs are estimated to be 19.9 to 21.6% of the original construction costs for High and Minimum Recommended Frequency maintenance program scenarios, respectively. | |||

#Rehabilitation costs for No Infiltration designs are estimated to be 20.2 to 21.9% of the original construction costs for High and Minimum Recommended Frequency maintenance program scenarios, respectively. | |||

#Maintenance and rehabilitation costs over a 25 year time period for the Minimum Recommended maintenance scenario are estimated to be roughly equivalent to the original construction cost for Partial Infiltration and No Infiltration designs (96.2% and 97.8%, respectively), and 1.21 times the original construction cost for Full Infiltration design. | |||

#Maintenance and rehabilitation costs over a 25 year time period for the High Frequency maintenance scenario are estimated to be 1.32 times the original construction costs for Partial Infiltration, 1.34 times for No Infiltration designs, and 1.67 times for Full Infiltration designs. | |||

#Maintenance and rehabilitation costs over a 50 year time period for the Minimum Recommended Frequency maintenance scenario are estimated to be approximately 1.76 times the original construction cost for Partial Infiltration designs, 1.79 times the original construction cost for No Infiltration designs, and 2.21 times the original construction cost for Full Infiltration designs. | |||

#Maintenance and rehabilitation costs over a 50 year time period for the High Frequency maintenance scenario are estimated to be approximately 2.40 times the original construction cost for Partial Infiltration designs, 2.44 times the original construction cost for No Infiltration designs, and 3.04 times the original construction cost for Full Infiltration designs. | |||

==Inspection Field Data Sheet== | ==Inspection Field Data Sheet== | ||

Feel free to '''download''' (downward facing arrow on the top righthand side) and '''print''' (Pinter emoticon on top right hand side) the following [[Bioretention]] and [[Dry swale]] Inspection Field Data Form developed by TRCA, STEP and its partners for the [https://sustainabletechnologies.ca/app/uploads/2016/08/LID-IM-Guide-2016-1.pdf Low Impact Development Stormwater Management Practice Inspection and Maintenance Guide]<ref>STEP. 2016. Low Impact Development Stormwater Management Practice Inspection and Maintenance Guide. https://sustainabletechnologies.ca/app/uploads/2016/08/LID-IM-Guide-2016-1.pdf</ref>. | Feel free to '''download''' (downward facing arrow on the top righthand side) and '''print''' (Pinter emoticon on top right hand side) the following [[Bioretention]] and [[Dry swale]] Inspection Field Data Form developed by TRCA, STEP and its partners for the [https://sustainabletechnologies.ca/app/uploads/2016/08/LID-IM-Guide-2016-1.pdf Low Impact Development Stormwater Management Practice Inspection and Maintenance Guide]<ref>STEP. 2016. Low Impact Development Stormwater Management Practice Inspection and Maintenance Guide. https://sustainabletechnologies.ca/app/uploads/2016/08/LID-IM-Guide-2016-1.pdf</ref>. | ||

The 8 page document prompts users to fill out details previously mentioned above on this page in other sections about various zones associated with [[Bioretention]] and [[Dry swale]] features (i.e. inlets, perimeter of the feature, filter bed, outlets, etc.) and describe why each area is a pass or fail, and if remediate action is required and under what timeframe it would be completed by. Furthermore, the forms prompt the reviewer to determine what type of inspection is being conducted for the feature in question: Construction (C), Routine Operation (RO), Maintenance Verification (MV), or Performance Verification (PV). <br> | The 8 page document prompts users to fill out details previously mentioned above on this page in other sections about various zones associated with [[Bioretention]] and [[Dry swale]] features (i.e. inlets, perimeter of the feature, filter bed, outlets, etc.) and describe why each area is a pass or fail, and if remediate action is required and under what timeframe it would be completed by. Furthermore, the forms prompt the reviewer to determine what type of inspection is being conducted for the feature in question: Construction (C), Routine Operation (RO), Maintenance Verification (MV), or Performance Verification (PV). <br> | ||

<br> | <br> | ||

[[File:Continuous monitoring.PNG|thumb|300px|Staff conducting monitoring of bioretention's water level with the use of a [[Digital technologies|continuous water level data logger]] located in the feature's[[Wells|monitoring well]]. [https://sustainabletechnologies.ca/app/uploads/2018/02/Bioretention-and-Dry-Swales-Fact-Sheet.pdf Photo Source: TRCA, 2018]<ref>TRCA. 2018. Inspection and Maintenance of Stormwater Best Management Practices - Bioretention. Fact Sheet. https://sustainabletechnologies.ca/app/uploads/2018/02/Bioretention-and-Dry-Swales-Fact-Sheet.pdf</ref>]] | |||

<pdf width="900" height="800">File:Bio Swale Inspection Sheet.pdf</pdf> | <pdf width="900" height="800">File:Bio Swale Inspection Sheet.pdf</pdf> | ||

==References== | ==References== | ||

Latest revision as of 15:59, 12 August 2022

Overview[edit]

Bioretention treats stormwater by slowing it down, filtering it through soil and plant roots, soaking it into the ground and evaporating it back to the atmosphere. Runoff water is delivered to the practice through inlets such as curb cuts, spillways or other concrete structures, sheet flow from pavement edges, or pipes connected to catchbasins or roof downspouts. The planting bed and side slopes are typically covered with a mixture of plants, mulch and stone. Water in excess of its storage capacity overflows to another BMP or the municipal storm sewer. Filtered water is either infiltrated into the underlying soil to replenish groundwater, or collected by a sub-drain (i.e., underground perforated pipe) and discharged to the storm sewer system or another BMP. Depending on the permeability of the underlying soil or other constraints, it may be designed with no sub-drain for full infiltration, with a sub-drain for partial infiltration, or with an impermeable liner and sub-drain for a no infiltration practice. The sub-drain pipe may feature a flow restrictor (e.g., orifice cap or valve) for gradually releasing detained water and optimizing the amount drained by infiltration. Key components of bioretention practices for inspection and maintenance described further below.

Key components of bioretention/bioswales to pay close attention to are the:

Trash, debris and sediment builds up at these locations and can prevent water from flowing into or out of the practice.

Associated Practices[edit]

- Bioretention cell: A flat-bottomed, depressed planting bed containing filter media soil, a gravel water storage layer and optional sub-drain pipe(s); Also known as a rain garden.

- Stormwater planters: A bioretention cell contained within an engineered (e.g., concrete) structure.

- Biofilter: Bioretention cell or swale with an impermeable liner or containment structure and sub-drain.

- Bioswale / Dry swale or Bioretention swale: A gently sloping, linear oriented bioretention practice designed to be capable of conveying water across an elevation gradient. Also known as a bioswale or dry swale.

- Stormwater Tree Trenches: Linear tree planting structures that feature supported impermeable or permeable pavements that promote healthy tree growth while also helping to manage runoff. Consist of subsurface trenches filled with modular structures and growing medium, or structurally engineered soil medium, supporting the overlying sidewalk.

Inspection and Testing Framework[edit]

Component |

Indicators |

Construction Inspection |

Assumption Inspection |

Routine Operation Inspection |

Verification Inspection |

|---|---|---|---|---|---|

| Contributing Drainage Area | |||||

| CDA condition | x | x | x | x | |

| Inlet | |||||

| Inlet/Flow Spreader Structural Integrity | x | x | x | ||

| Inlet/Flow Spreader Structural Integrity | x | x | x | x | |

| Pretreatment sediment accumulation | x | x | x | ||

| Inlet erosion | x | x | |||

| Perimeter | |||||

| BMP dimensions | x | x | x | ||

| Side slope erosion | x | x | |||

| Surface ponding area | x | x | x | ||

| Filter Bed | |||||

| Standing water | x | x | x | ||

| Trash | x | x | |||

| Filter bed erosion | x | x | |||

| Mulch depth | x | x | x | x | |

| Filter bed sediment accumulation | x | x | x | ||

| Surface ponding depth | x | x | x | ||

| Filter bed surface sinking | x | x | x | ||

| Check dams | x | x | x | x | |

| Planting Area | |||||

| Vegetation cover | x | x | x | x | |

| Vegetation condition | x | x | |||

| Vegetation composition | x | x | x | ||

| Outlet | |||||

| Monitoring well condition | x | x | x | x | |

| Sub-drain/Perforated pipe obstruction | x | x | |||

| Overflow outlet obstruction | x | x | x | x |

Component |

Indicators |

Construction Inspection |

Assumption Inspection |

Routine Operation Inspection |

Verification Inspection | |

|---|---|---|---|---|---|---|

| Testing Indicators | ||||||

| Soil characterization testing | x | x | (x) | |||

| Sediment accumulation testing | x | x | x | x | ||

| Surface infiltration rate testing | x | (x) | ||||

| Natural or simulated storm event testing | x | (x) | ||||

| Continuous monitoring | x | (x) | ||||

| Note: (x) denotes indicators to be used for Performance Verification inspections only (i.e., not for Maintenance Verification inspections) | ||||||

Construction Inspection Tasks[edit]

Construction inspections take place during several points in the construction sequence, specific to the type of LID BMP, but at a minimum should be done weekly and include the following:

- During site preparation, prior to BMP excavation and grading to ensure the CDA is stabilized or that adequate ESCs or flow diversion devices are in place and confirm that construction materials meet design specifications

- At completion of excavation and grading, prior to installation of pipes/sewers and backfilling to ensure depths, slopes and elevations are acceptable

- At completion of installation of pipes/sewers, prior to backfilling to ensure slopes and elevations are acceptable

- After final grading, prior to planting to ensure depths, slopes and elevations are acceptable;

- Prior to hand-off points in the construction sequence when the contractor responsible for the work changes (i.e., hand-offs between the storm sewer servicing, paving, building and landscaping contractors)

- After every large storm event (e.g., 15 mm rainfall depth or greater) to ensure Erosion Sediment Controls (ESCs) and pretreatment or flow diversion devices are functioning and adequately maintained. View the table below, which describes critical points during the construction sequence when inspections should be performed prior to proceeding further. You can also download and print the table here

Construction Sequence Step & Timing |

Inspection Item |

Observations* |

|---|---|---|

| Site Preparation - after site clearing and grading, prior to BMP excavation and grading | Natural heritage system and tree protection areas remain fenced off | |

| ESCs protecting BMP layout area are installed properly | ||

| CDA is stabilized or runoff is diverted around BMP layout area | ||

| BMP layout area has been cleared and is staked/delineated | ||

| Benchmark elevation(s) are established nearby | ||

| Construction materials have been confirmed to meet design specifications | ||

| BMP Excavation and Grading - prior to installation of pipes/sewers and backfilling | Excavation location, footprint, depth and slopes are acceptable | |

| Excavated soil is stockpiled outside the CDA | ||

| Embankments/berms (elevations, slopes, compaction) are acceptable | ||

| Excavation bottom and sides roughened to reduce smearing and compaction | ||

| BMP Installation – after installation of pipes/sewers, prior to backfilling | Structural components (e.g., foundation, walls) installed according to plans, if applicable | |

| Impermeable liner installed correctly, if applicable | ||

| Installations of sub-drain pipes (e.g., locations, elevations, slopes), standpipes/monitoring wells are acceptable | ||

| Sub-drain trench dams installed correctly (location, elevation) | ||

| Landscaping – after final grading, prior to planting | Filter bed depth and surface elevations at inlets are acceptable | |

| Maximum surface ponding depth is acceptable | ||

| Filter bed is free of ruts, local depressions and not overly compacted | ||

| Planting material meets approved planting plan specifications (plant types and quantities) | ||

| Note: for Observation Column: S = Satisfactory; U = Unsatisfactory; NA = Not Applicable* | ||

Routine Maintenance - Key Components and I&M Tasks[edit]

Regular inspections (twice annually, at a minimum) done as part of routine maintenance tasks over the operating phase of the BMP life cycle to determine if maintenance task frequencies are adequate and determine when rehabilitation or further investigations into BMP function are warranted.

Table below describes routine maintenance tasks for bioretention practices, organized by BMP component, along with recommended minimum frequencies. It also suggests higher frequencies for certain tasks that may be warranted for BMPs located in highly visible locations or those receiving flow from high traffic areas (vehicle or pedestrian). Tasks involving removal of trash, debris and sediment and weeding/trimming of vegetation for BMPs in such contexts may need to be done more frequently (i.e., higher standards may be warranted).

Individuals conducting vegetation maintenance and in particular, weeding (i.e., removal of undesirable vegetation), should be familiar with the species of plants specified in the planting plan and experienced in plant identification and methods of removing/controlling noxious weeds. Key resources on these topics are provided below at the links provided:

- Agriculture and Agri-food Canada’s Weed Info database

- Ontario Ministry of Agriculture, Food and Rural Affairs’ Ontario Weed Gallery

- Ontario Ministry of Agriculture, Food and Rural Affairs’ Noxious Weeds In Ontario list

- Ontario Invasive Plant Council’s Quick Reference Guide to Invasive Plant Species

- Oregon State University Stormwater Solutions, 2013, Field Guide: Maintaining Rain Gardens, Swales and Stormwater Planters, Corvallis, OR.

- Plants of Southern Ontario (book), 2014, by Richard Dickinson and France Royer, Lone Pine Publishing, 528 pgs.

- Weeds of North America (book), 2014, by Richard Dickinson and France Royer, University of Chicago Press, 656 pgs.

| Comnponent | Description | Inspection & Maintenance Tasks | (Pass) Photo Example | (Fail) Photo Example |

|---|---|---|---|---|

| Contributing Drainage Area (CDA) |

Area(s) from which runoff directed to the BMP originates; includes both impervious and pervious areas. |

|

||

| Pretreatment |

Devices or features that retain trash, debris and sediment; help to extend the operating life cycle; examples are eavestrough screens, catch basin inserts and sumps, oil and grit separators, geotextile-lined inlets, gravel trenches, grass filter strips and forebays. |

|

Forebay is free of sediment, trash and debris and recently maintained. The large stones in the feature are used to slow down and spread out inflowing water into the feature and they remain well arranged and in place. |

An erosion gully occurring where bare soil is starting to become visible on the grass filter strip pretreatment feature at the inlet, thus indicating it is not effectively slowing and spreading out the inflow of stormwater to the BMP. |

| Inlets |

Structures that deliver water to the BMP (e.g., Curb cuts, spillways, pavement edges, catch basins, pipes). |

|

||

| Perimeter |

Side slopes or structures that define the BMP footprint; may be covered by a mixture of vegetation, mulch and stone with slopes up to 2:1 (H:V), or concrete or masonry structures with vertical walls. |

|

||

| Filter Bed |

Flat or gently sloping area composed of a 0.5 to 1 m deep layer of filter media soil covered by a mixture of vegetation, mulch and stone where surface ponding and filtration of runoff occurs. |

|

||

| Vegetation |

A mixture of deep rooting perennial plants, tolerant to both wet and dry conditions and salt (if receiving pavement runoff); can include grasses, flowers, shrubs and trees; roots uptake water and return it to the atmosphere; provide habitat for organisms that break down trapped pollutants and help maintain soil structure and permeability. |

|

||

| Overflow Outlet |

Structures that convey overflows to another BMP or municipal storm sewer. |

|

||

| Sub-drain |

Optional component; perforated pipe(s) surrounded by gravel and may be wrapped in geotextile filter fabric; installed below the filter media soil layer to collect and convey treated water to an adjacent drainage system; may also include a flow restrictor. |

|

||

| Monitoring well |

Perforated standpipe that extends from the bottom of the BMP to above the invert of the overflow outlet. Allows measurement of subsurface water level to track drainage performance over time. |

|

Tips to Preserve Basic BMP Function[edit]

- Maintain grading of the filter bed (or grass filter strip if present) at curb cut inlets so at least 5 cm of the back of the curb is visible through regular sediment removal and regrading.

- To avoid over-compaction of the filter media soil, any maintenance tasks involving vehicle or foot traffic on the filter bed should not be performed during wet weather.

- For bioretention with sod (i.e., turf grass) as vegetation cover, maintain with a push mower or the lightest mulching ride mower available and core aerate and dethatch annually in the spring to help maintain permeability.

- Pruning of mature trees should be performed under the guidance of a Certified Arborist.

- Woody vegetation should not be planted or allowed to become established where snow will be piled/stored during Winter.

- Removal of sediment from the filter bed surface should be done with rake and shovel, or vacuum equipment to minimize plant disturbance. If a small excavator is to be used, keep it off the BMP footprint to avoid damage to side slopes/embankments and over-compaction of the filter media.

Rehabilitation & Repair[edit]

Table below provides guidance on rehabilitation and repair work specific to bioretention and dry swales organized according to BMP component.

| Component | Problem | Rehabilitation Tasks |

|---|---|---|

| Inlets |

Inlet is producing concentrated flow and causing filter bed erosion. |

|

| Filter Bed | Local or average sediment accumulation ≥ 5 cm in depth. |

|

| Surface ponding remains for >48 hours or surface infiltration rate is <25 mm/h. |

| |

| Damage to filter bed or slide slope is present (e.g., erosion rills, animal burrows, sink holes, ruts) |

| |

| Vegetation |

Vegetation is not thriving and filter media is low in organic matter (<3%) or extractable phosphorus (<10 mg/kg) |

|

| Sub-drain |

Sub-drain perforated pipe is obstructed by sediment or roots. |

|

Technician conducting sediment removal to ensure infiltration rates for the

practice are able to maintain > 25 mm/h. Photo Source: TRCA, 2018[5]

Inspection Time Commitments and Costs[edit]

Estimates are based on a typical partial infiltration bioretention design (i.e., includes a sub-drain); estimates for other designs (i.e., full infiltration and no-infiltration) can be found in the Low Impact Development (LID) Stormwater Management Practice Inspection and Maintenance Guide

Estimates of the life cycle costs of inspection and maintenance have been produced using the latest version of the LID Life Cycle Costing Tool for three design variations (full infiltration, partial infiltration and no infiltration) to assist stormwater infrastructure planners, designers and asset managers with planning and preparing budgets for potential LID features.

Assumptions for the above costs and the following table below are based on the following:

- Capital costs included within the category of construction include those related to site assessment, and conceptual and detailed design related tasks such as borehole analysis and soil testing. All material, delivery, labour, equipment (rental, operation, operator), hauling and disposal costs are accounted for within the construction costs of the facility. Standard union costs were derived from the RSMeans database in 2010 and have been adjusted for 5 year inflation of 8.79% (2010 to June, 2015).

- Costs include overhead and inflation to represent contractor pricing. It was assumed the practice is part of a new development (i.e., not a retrofit), thereby excluding (de)mobilization costs unless a particular piece of equipment would not normally have been present at the site. Additionally, it was assumed that excavated soil associated with construction of the BMP would be reused elsewhere on site. Overhead costs were presumed to consist of construction management (4.5%), design (2.5%), small tools (0.5%), clean up (0.3%) and other (2.2%).

- For maintenance frequencies and requirements and the life span of each practice are based on both literature and practical experience. Life cycle and associated maintenance costs are evaluated over a 50 year timeframe, which is the typical period over which infrastructure decisions are made.

- For bioretention, it is assumed that some rehabilitation (e.g., rehabilitative maintenance) work will be needed on the filter bed surface once the BMP reaches 25 and 50 years of age in order to maintain functional drainage performance at an acceptable level. Included in the rehabilitation costs are (de)mobilization costs, as equipment would not have been present on site. Design costs were not included in the rehabilitation as it was assumed that the original LID practice design would be used to inform this work. The annual average maintenance cost does not include rehabilitation costs and therefore represents an average of routine maintenance tasks, as outlined in the Table under section, Routine Maintenance - Key Components and I&M Tasks above. All cost value estimates represent the net present value (NPV) as the calculation takes into account average annual interest (2%) and discount (3%) rates over the evaluation time periods.

- For all bioretention design variations, the CDA has been defined as a 2,000 m2 impervious pavement area plus the footprint area of a bioretention cell that is 133 m2 in size, as per design recommendations. The impervious area to pervious area ratio (I:P ratio) used to size the BMP footprint is 15:1, which is the maximum ratio recommended in the LID SWM Planning and Design Guide (CVC & TRCA, 2010)[9]. It is assumed that water drains to the cell through curb inlets spaced 6 m apart with

stone cover on the filter bed at the inlets to dissipate the energy of the flowing water.

- While orientation (i.e., cell versus swale) and choice of components (e.g., inlet/outlet structures etc.) can vary widely, design variations for bioretention practices can be broken down into three main categories. They can be designed to drain through infiltration into the underlying subsoil alone (i.e., Full Infiltration design, no sub-drain), through the combination of a sub-drain and infiltration into the underlying subsoil (i.e., Partial Infiltration design, with a sub-drain), or through a sub-drain alone (i.e., No Infiltration or “filtration only” design, with a sub-drain and impermeable liner). For Full Infiltration systems, an overflow is provided for storms up to 37 mm based on a subsoil infiltration rate of 20 mm/hour. Two standpipe wells are part of the design (one subdrain inspection/flushing port at the upstream end and one sub-surface water storage reservoir monitoring well at the downstream end). Partial Infiltration systems have a sub-surface water storage reservoir with a perforated pipe sub-drain within it. The depth of the reservoir is sized to store flow from a 25 mm rain event over the CDA based on native soil infiltration rate of 10 mm/hour. The No Infiltration system includes an impermeable liner between the base and sides of the BMP and surrounding native sub-soil, to prevent infiltration.

- Estimates of the life cycle costs of bioretention and dry swales in Canadian dollars per unit CDA ($/m2) are presented in the table below. LID Life Cycle Costing Tool allows users to select what BMP type and design variation applies, and to use the default assumptions to generate planning level cost estimates.

- Users can also input their own values relating to a site or area, design, unit costs, and inspection and maintenance task frequencies to generate customized cost estimates, specific to a certain project, context or stormwater infrastructure program.

- For all BMP design variations and maintenance scenarios, it is assumed that rehabilitation of part or all of the filter bed surface will be necessary once the BMP reaches 25 and 50 years of age to maintain acceptable surface drainage performance (e.g., surface ponding drainage time). Filter bed rehabilitation for bioretention and dry swales is assumed to typically involve the tasks outlined under section, Routine Maintenance - Key Components and I&M Tasks above.

Notes:

- Estimated life cycle costs represent NPV of associated costs in Canadian dollars per squaremetre of CDA ($/m2).

- Average annual maintenance cost estimates represent NPV of all costs incurred over the time period and do not include rehabilitation costs.

- Rehabilitation cost estimates represent NPV of all costs related to repair work assumed to occur every 25 years, including those associated with inspection and maintenance over a two (2) year establishment period for the plantings.

- Full Infiltration design life cycle costs are lower than Partial and No Infiltration designs due to the absence of a sub-drain to construct, inspect and routinely flush.

- Rehabilitation costs for Full Infiltration designs are estimated to be 26.4 to 28.4% of the original construction costs for High and Minimum Recommended Frequency maintenance program scenarios, respectively.

- Rehabilitation costs for Partial Infiltration designs are estimated to be 19.9 to 21.6% of the original construction costs for High and Minimum Recommended Frequency maintenance program scenarios, respectively.

- Rehabilitation costs for No Infiltration designs are estimated to be 20.2 to 21.9% of the original construction costs for High and Minimum Recommended Frequency maintenance program scenarios, respectively.

- Maintenance and rehabilitation costs over a 25 year time period for the Minimum Recommended maintenance scenario are estimated to be roughly equivalent to the original construction cost for Partial Infiltration and No Infiltration designs (96.2% and 97.8%, respectively), and 1.21 times the original construction cost for Full Infiltration design.

- Maintenance and rehabilitation costs over a 25 year time period for the High Frequency maintenance scenario are estimated to be 1.32 times the original construction costs for Partial Infiltration, 1.34 times for No Infiltration designs, and 1.67 times for Full Infiltration designs.

- Maintenance and rehabilitation costs over a 50 year time period for the Minimum Recommended Frequency maintenance scenario are estimated to be approximately 1.76 times the original construction cost for Partial Infiltration designs, 1.79 times the original construction cost for No Infiltration designs, and 2.21 times the original construction cost for Full Infiltration designs.

- Maintenance and rehabilitation costs over a 50 year time period for the High Frequency maintenance scenario are estimated to be approximately 2.40 times the original construction cost for Partial Infiltration designs, 2.44 times the original construction cost for No Infiltration designs, and 3.04 times the original construction cost for Full Infiltration designs.

Inspection Field Data Sheet[edit]

Feel free to download (downward facing arrow on the top righthand side) and print (Pinter emoticon on top right hand side) the following Bioretention and Dry swale Inspection Field Data Form developed by TRCA, STEP and its partners for the Low Impact Development Stormwater Management Practice Inspection and Maintenance Guide[11].

The 8 page document prompts users to fill out details previously mentioned above on this page in other sections about various zones associated with Bioretention and Dry swale features (i.e. inlets, perimeter of the feature, filter bed, outlets, etc.) and describe why each area is a pass or fail, and if remediate action is required and under what timeframe it would be completed by. Furthermore, the forms prompt the reviewer to determine what type of inspection is being conducted for the feature in question: Construction (C), Routine Operation (RO), Maintenance Verification (MV), or Performance Verification (PV).

References[edit]

- ↑ TRCA. 2016. Fact Sheet - Inspection and Maintenance of Stormwater Best Management Practices: Bioretention. https://sustainabletechnologies.ca/app/uploads/2018/02/Bioretention-and-Dry-Swales-Fact-Sheet.pdf

- ↑ STEP. 2016. Low Impact Development Stormwater Management Practice Inspection and Maintenance Guide. https://sustainabletechnologies.ca/app/uploads/2016/08/LID-IM-Guide-2016-1.pdf

- ↑ STEP. 2016. Low Impact Development Stormwater Management Practice Inspection and Maintenance Guide. https://sustainabletechnologies.ca/app/uploads/2016/08/LID-IM-Guide-2016-1.pdf

- ↑ TRCA. 2019. Low Impact Development Stormwater Inspection and Maintenance Guide. https://sustainabletechnologies.ca/home/urban-runoff-green-infrastructure/low-impact-development/low-impact-development-stormwater-practice-inspection-and-maintenance-guide/

- ↑ TRCA. 2018. Inspection and Maintenance of Stormwater Best Management Practices - Bioretention. Fact Sheet. https://sustainabletechnologies.ca/app/uploads/2018/02/Bioretention-and-Dry-Swales-Fact-Sheet.pdf

- ↑ TRCA. 2018. Inspection and Maintenance of Stormwater Best Management Practices. Bioretention - Fact Sheet. https://sustainabletechnologies.ca/app/uploads/2018/02/Bioretention-and-Dry-Swales-Fact-Sheet.pdf

- ↑ TRCA. 2018. Inspection and Maintenance of Stormwater Best Management Practices. Bioretention - Fact Sheet. https://sustainabletechnologies.ca/app/uploads/2018/02/Bioretention-and-Dry-Swales-Fact-Sheet.pdf

- ↑ TRCA. 2018. Inspection and Maintenance of Stormwater Best Management Practices. Bioretention - Fact Sheet. https://sustainabletechnologies.ca/app/uploads/2018/02/Bioretention-and-Dry-Swales-Fact-Sheet.pdf

- ↑ CVC and TRCA. 2010. Low Impact Development Stormwater Management Planning and Design Guide. Version 1.0. https://cvc.ca/wp-content/uploads/2014/04/LID-SWM-Guide-v1.0_2010_1_no-appendices.pdf

- ↑ TRCA. 2018. Inspection and Maintenance of Stormwater Best Management Practices. Bioretention - Fact Sheet. https://sustainabletechnologies.ca/app/uploads/2018/02/Bioretention-and-Dry-Swales-Fact-Sheet.pdf

- ↑ STEP. 2016. Low Impact Development Stormwater Management Practice Inspection and Maintenance Guide. https://sustainabletechnologies.ca/app/uploads/2016/08/LID-IM-Guide-2016-1.pdf

- ↑ TRCA. 2018. Inspection and Maintenance of Stormwater Best Management Practices - Bioretention. Fact Sheet. https://sustainabletechnologies.ca/app/uploads/2018/02/Bioretention-and-Dry-Swales-Fact-Sheet.pdf