Infiltration Trench: Life Cycle Costs

Overview[edit]

Infiltration trenches (also referred to as ‘infiltration galleries’) are design variations that consist of linear, rectangular or trapezoidal shape, with a bottom generally between 0.6 and 2.4 m wide. Linear trench geometries will drain faster than round or square shapes due to their larger perimeters. These geotextile-lined excavation facilities should have a nearly level or gently sloping bottom grade to spread flow evenly. Similar to soakaways, they are also filled with stone or other void-forming structures. They are well suited to sites where available space for infiltration is limited to strips of land between buildings or properties, or along road right-of-ways. STEP has prepared life cycle costs estimates for each design configuration, based on a 2,000 m2 asphalt drainage area, runoff control target of 25 mm depth and 72 hour drainage period, for comparison which can be viewed below. To generate your own life cycle cost estimates customized to the development context, design criteria, and constraints applicable to your site, access the updated LID Life Cycle Costing Tool (LCCT) here.

Design Assumptions[edit]

Infiltration trenches are an ideal technology for installing below any type of landscape with requirements to infiltrate excess stormwater whilst conveying excess. Components include: layers of coarse aggregate (to bed the pipe, store and redistribute water), perforated pipe or udnerdrains and geotextile.

Design and operation and maintenance program assumptions used to generate cost estimates are based on tool default values and the following STEP recommendations:

- Native soil infiltration rates for Full, Partial and No Infiltration Design scenarios were assumed to be 20 mm/h, 10 mm/h and 2 mm/h, respectively, and a safety factor of 2.5 was applied to calculate the design infiltration rate.

- Operation and maintenance (O&M) cost estimates assume annual inspections, removal of trash and debris twice a year, removal of sediment from pretreatment structures annually, and removal of weeds twice a year (where applicable). Verification inspections are included every 5 years to confirm adequate maintenance, and every 15 years to confirm adequate drainage performance through in-situ surface infiltration rate testing (where applicable)

- Designed with an impervious drainage area to treatment facility area ratio of between 5:1 and a maximum of 20:1.

- Length to width ratio of infiltration trench area recommended from facilities receiving road or parking lot runoff is 10:1.

- Should be set back at least four (4) metres from building foundations.

- Overflow pipes should discharge to pervious areas located at least 2m from building foundations and slope away from building or to a storm sewer.

- Default filter media depth of 1.0 metres to accommodate trees in planting plan.

- Trench bottom width is generally between 0.60 and 2.4 metres.

- Default maximum depth of 3 - 4 metres, as there are cost implications with using trench boxes to retain the side walls.

- An underdrain (300 mm diameter perforated pipe) is included in Partial Infiltration & Full Infiltration design configurations.

Notes[edit]

- Designs include pretreatment through hydrodynamic separator (Oil and Grit Separator).

- Operation and maintenance cost estimates assume rehabilitation of the filter media bed surface is required after 25 years of operation.

- The tool calculates costs for new (greenfield) development contexts and includes costs for contractor overhead and profit, material, delivery, labour, equipment (rental, operating and operator costs), hauling and disposal.

- Land value and equipment mobilization and demobilization costs are not included, assuming BMP construction is part of overall development site construction.

- Design and Engineering cost estimates are not calculated by the tool and must be supplied by the user.

- The tool adds 10% contingency and additional overhead as default.

- All cost estimates are in Canadian dollars and represent the net present value (NPV) as the tool takes into account average annual interest and discount rates over the 25 and 50 year operating life cycle periods.

- Unit costs are based on 2018 RSMeans standard union pricing.

- Additional costs associated with retrofit or redevelopment contexts is assumed to be 16% of the cost estimate for new (greenfield) construction contexts.

- Retrofit construction cost estimates are included in the 'Costs Summary' section for comparison.

- Retrofit construction cost estimates are included in the 'Costs Summary' section for comparison.

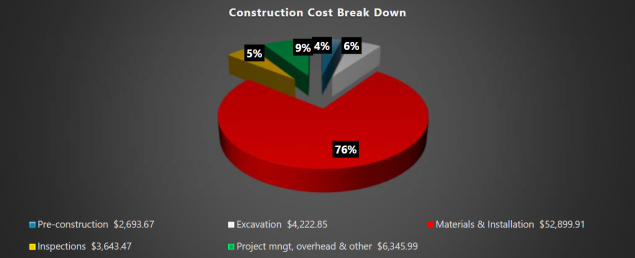

Construction Costs[edit]

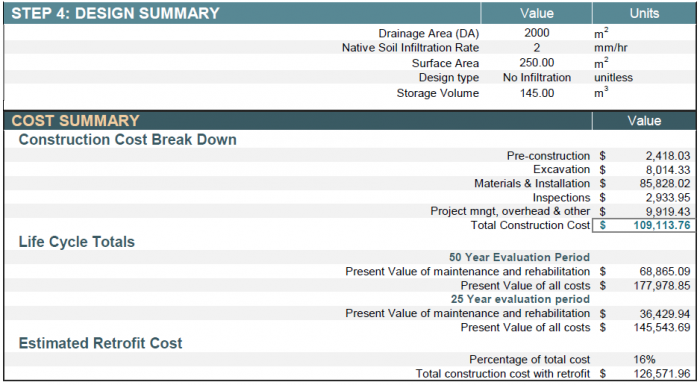

Note: Please click on each image to enlarge to view associated construction cost estimates.

Above you can find a cost breakdown of a 1000m2 in two different configurations:

As can be seen, regardless of design configuration, Material & Installation expenses represent the largest portion of total construction costs (75 to 76%).

Life Cycle Costs[edit]

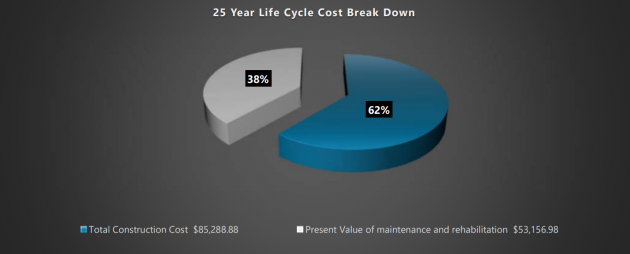

Below are capital and life cycle cost estimates for the two infiltration trench configurations over 25- and 50-year time periods. The estimates of maintenance and rehabilitation (life cycle) costs represent net present values. Operation and maintenance costs are predicted to represent 38% of total life cycle costs over the 25-year evaluation period, and increase to 51% of total life cycle costs over the 50-year period, due to increased levels of litter removal, replacement of filter cloth and disposal of collected sediment (every 4 - 8 years), cleaning out the catchbasin and the Oil and Grit Separator/Hydro Dynamic Separator, annually, as well as flushing the internal pipes every 10 years.

25-Year life cycle cost break down[edit]

Note: Click on each image to enlarge to view associated life cycle cost estimate.

50-Year life cycle cost break down[edit]

Note: Click on each image to enlarge to view associated life cycle cost estimate.

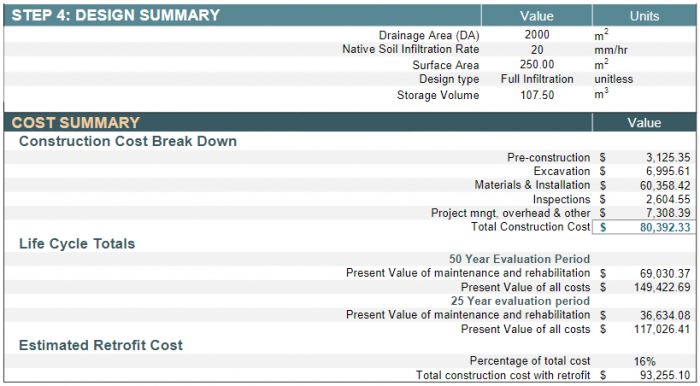

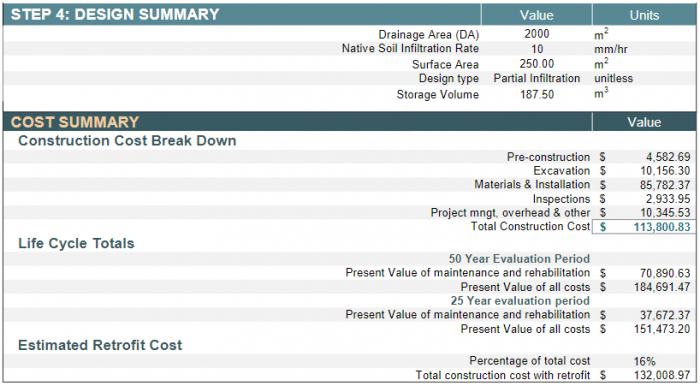

Cost Summary Tables[edit]

Total life cycle cost estimates for the three Bioretention configurations vary substantially with the Partial Infiltration design being highest ($113,800.83), followed closely by No Infiltration design ($109,113.76), and Full Infiltration design being the lowest ($80,392.33).

It is notable that a sensitivity analysis was conducted in 2019 to compare construction cost estimates generated by the tool to actual costs of implemented projects. The analysis found that tool estimates were typically within ±14% of actual construction costs[2]

Full Infiltration[edit]

Partial Infiltration[edit]

No Infiltration (Filtration Only)[edit]

References[edit]

- ↑ Hydrologic Assessment of LID Honda Campus, Markham, ON - TECHNICAL BRIEF. Accessed Dec 19 2022. https://sustainabletechnologies.ca/app/uploads/2015/07/Honda_TechBrief_July2015.pdf

- ↑ Credit Vally Conservation (CVC). 2019. Life-cycle costing tool 2019 update: sensitivity analysis. Credit Valley Conservation, Mississauga, Ontario. https://sustainabletechnologies.ca/app/uploads/2020/04/LCCT-Sensitivity-Analysis_March2020.pdf

- ↑ Performance Comparison of Surface and Underground Stormwater Infiltration Practices - TECHNICAL BRIEF. Low Impact Development Series. https://sustainabletechnologies.ca/app/uploads/2016/08/BioVSTrench_TechBrief__July2015.pdf