Inspection and Maintenance: Green Roofs

Overview[edit]

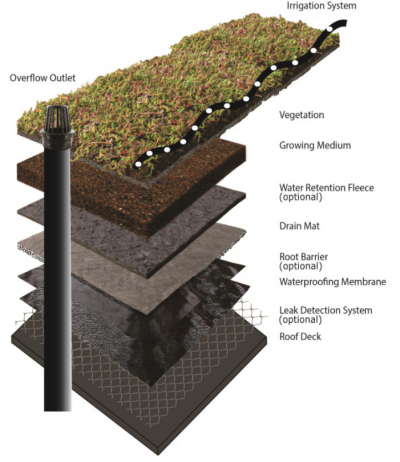

Green roofs are engineered rooftop design features that allow the growth of vegetation on rooftops and have numerous benefits. These LID BMPs can also be referred to as vegetated roofs, rooftop gardens or eco-roofs. A green roof acts like a lawn, meadow or garden by intercepting and absorbing a portion of the rainwater or snowmelt that falls on it. The typical layers of a green roof (in ascending order from the roof surface) include a water-proofing membrane, drainage layer, lightweight growing media layer and the vegetation. Excess water that is not absorbed by the growing media or vegetation is collected by the underlying drainage layer, directed to outlet structures and conveyed via the roof drainage system to another BMP or the municipal storm sewer system. A portion of the water absorbed by green roofs is returned to the atmosphere by evaporation and transpiration by plants. Green roofs are typically designed to retain precipitation from small to medium-sized (e.g., 5 to 25 mm rainfall depth) storm events. Overflow outlets are necessary to safely convey flows from major storm events.

Some of the benefits of green roofs include:

- The ability to reduce the quantity of pollutants and runoff being discharged to municipal storm sewers and receiving waters (i.e., rivers, lakes and wetlands);

- Growing media and plants retain pollutants deposited from the atmosphere and reduce metals and other pollutants from conventional roof materials transported by runoff;

- Improve the energy efficiency of the building due to their insulating properties;

- Reduce the urban heat island effect;

- Can provide food and shelter for pollinators;

- Can provide aesthetic value as attractive landscaped features.

Key components of Underground Infiltration Systems to pay close attention to are the:

Associated Practices[edit]

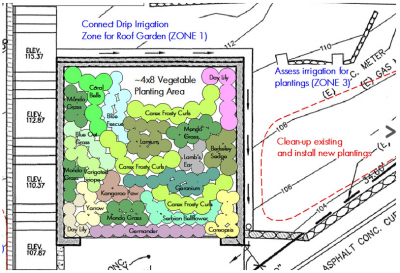

- Intensive green roofs contain greater than 15 cm depth of growing media, can be planted with deeply rooted plants (e.g., shrubs and trees) and can be designed to handle pedestrian traffic.

- Extensive green roofs consist of a thinner growing media layer (15 cm depth or less) and are typically planted with.

- Blue roofs are systems that temporarily capture rainwater using the roof as storage and allow it to evaporate and/or to be used for non-potable requirements (i.e. irrigation, toilet flushing, truck washing) and ultimately offset potable water demands.

Inspection and Testing Framework[edit]

Component |

Indicators |

Construction Inspection |

Assumption Inspection |

Routine Operation Inspection |

Verification Inspection |

|---|---|---|---|---|---|

| Perimeter | |||||

| BMP dimensions | x | x | x | ||

| Growing medium/filter bed | |||||

| Green roof structural integrity | x | x | x | ||

| Standing water | x | x | x | ||

| Filter bed erosion | x | x | |||

| Vegetation | |||||

| Vegetation cover | x | x | x | x | |

| Vegetation condition | x | x | |||

| Vegetation composition | x | x | x | ||

| Overflow outlets | |||||

| Overflow outlet obstruction | x | x | x | x |

Component |

Indicators |

Construction Inspection |

Assumption Inspection |

Routine Operation Inspection |

Verification Inspection | |

|---|---|---|---|---|---|---|

| Testing Indicators | ||||||

| Soil characterization testing | x | x | (x) | |||

| Green roof irrigation system testing | x | x | x | |||

| Green roof leak detection testing | x | x | ||||

| Note: (x) denotes indicators to be used for Performance Verification inspections only (i.e., not for Maintenance Verification inspections) | ||||||

Construction Inspection Tasks[edit]

Construction inspections take place during several points in the construction sequence, specific to the type of LID BMP, but at a minimum should be done weekly and include the following:

- During site preparation, prior to BMP installation to ensure the roof structure is ready for green roof construction work and confirm that BMP layout area matches approved design drawings and that construction materials meet design specifications

- After installation of leak detection system (if applicable) to ensure it was done properly

- At installation of water-proofing membrane, prior to installation of root barrier, drainage layer and overflow outlets to ensure it was done properly and to confirm that slopes are acceptable

- After installation of root barrier, drainage layer (including filter fabric/layer) and overflow outlets, prior to installation of growing medium and plants to ensure it was done properly and confirm that depth and slopes are acceptable

- After installation of growing medium layer and plants to ensure it was done properly and to confirm depth, slopes and elevations at overflow outlets are acceptable; After installation of irrigation system to confirm system is functioning

- Prior to hand-off points in the construction sequence when the contractor responsible for the work changes (i.e., hand-offs between the building and green roof installation contractors)

- After every large storm event (e.g., 15 mm rainfall depth or greater) to ensure roof drainage or flow diversion devices are functioning and adequately maintained. You can also download and print the table here

Construction Sequence Step & Timing |

Inspection Item |

Observations* |

|---|---|---|

| Site Preparation - During site preparation, prior to BMP installation | Ensure the roof structure is ready for green roof construction work | |

| BMP layout area and dimensions match approved design drawings | ||

| CDA is stabilized or runoff is diverted around BMP layout area | ||

| Construction materials have been confirmed to meet design specifications | ||

| Leak detection System - After installation of leak detection system (if applicable), prior to installation of water-proofing membrane | Quality control check leak detection system installation | |

| Water Proofing Membrane – After installation of waterproofing membrane, prior to installation of root barrier, drainage layer and overflow outlets | Quality control check membrane installation | |

| Confirm that slopes conform with approved design drawings | ||

| Root barrier / Drainage layer and Overflow outlets – After installation of root barrier, drainage layer (including filter fabric) and overflow outlets, prior to installation of growing medium layer and plants | Quality control check root barrier and drainage layer installations | |

| Installation of drainage layer (e.g., depth and slope) is acceptable | ||

| Installations of overflow outlets (e.g., elevation and slope) are acceptable | ||

| Filter bed – After installation of filter bed (growing medium layer and plants) | Quality control check installation of any structural components of growing medium layer (if applicable) | |

| Installation of growing medium (e.g., depth, elevations at overflow outlets) is acceptable | ||

| Growing medium is free of ruts, local depressions | ||

| Planting material meets approved planting plan specifications (plant types and quantities) | ||

| Quality control check installation of erosion matting/protection (if applicable) | ||

| Irrigation System - After installation of irrigation system | Confirm installation is acceptable and system is functioning (through testing) |

Routine Maintenance - Key Components and I&M Tasks[edit]

Regular inspections (twice annually, at a minimum) done as part of routine maintenance tasks over the operating phase of the BMP life cycle to determine if maintenance task frequencies are adequate and determine when rehabilitation or further investigations into BMP function are warranted.

The table below describes routine maintenance tasks for green roofs, organized by BMP component, along with recommended minimum frequencies. It also suggests higher frequencies for certain tasks that may be warranted for BMPs located in highly visible or high pedestrian traffic locations or intensive green roofs featuring shrubs, trees and a wider variety of vegetation types. Tasks involving removal of trash, debris and weeding/trimming or replacement of dead plants may need to be done more frequently in such contexts. For further guidance on maintenance of vegetation cover on green roofs, refer to ASTM D2400/E2400M-06 Standard Guide for Selection, Installation and Maintenance of Plants for Green Roof Systems (ASTM International, 2015)[4]

Individuals conducting vegetation maintenance and in particular, weeding (i.e., removal of undesirable vegetation), should be familiar with the species of plants specified in the planting plan and experienced in plant identification and methods of removing/controlling noxious weeds. Key resources on these topics are provided below at the links provided:

- Agriculture and Agri-food Canada’s Weed Info database

- Ontario Ministry of Agriculture, Food and Rural Affairs’ Ontario Weed Gallery

- Ontario Ministry of Agriculture, Food and Rural Affairs’ Noxious Weeds In Ontario list

- Ontario Invasive Plant Council’s Quick Reference Guide to Invasive Plant Species

- Oregon State University Stormwater Solutions, 2013, Field Guide: Maintaining Rain Gardens, Swales and Stormwater Planters, Corvallis, OR.

- Plants of Southern Ontario (book), 2014, by Richard Dickinson and France Royer, Lone Pine Publishing, 528 pgs.

- Weeds of North America (book), 2014, by Richard Dickinson and France Royer, University of Chicago Press, 656 pgs.

| Component | Description | Inspection & Maintenance Tasks | (Pass) Photo Example | (Fail) Photo Example |

|---|---|---|---|---|

| Perimeter |

Separates the green roof from the roof edges and other structures; kept clear of vegetation and natural debris as a fire prevention measure. Parapets or other wind break structures may also be present around the perimeter to help prevent wind scour of growing media. |

|

||

| Growing medium/filter bed |

Flat or gently sloping area covered by growing medium and a mixture of plants. Growing medium varies according to the green roof system or product but is generally designed to be porous and lightweight with adequate fertility and moisture retention to support plant growth while maintaining drainage of excess water within a few hours after a storm or snowmelt event. May be covered by matting/other erosion control product to prevent rain/wind scour while plantings are becoming established. |

|

Standing water is present on the green roof surface and in the underdrain/sub-drain system and bare soil areas are visible (Photo Source: J.V. Heidler) | |

| Vegetation |

Plants should be tolerant of the harsh conditions prevalent on rooftops. Use of a wide variety of plants may improve resilience but complicates maintenance and may require staff or contractors trained in horticulture |

|

||

| Overflow Outlet |

Flows exceeding the storage capacity of the BMP are conveyed to an adjacent drainage system via an overflow outlet structure and the roof drainage system. |

|

||

| Irrigation System |

Most green roofs will require watering over their operating life cycle, especially during the first 2 months. Systems can range from simple hose bibs, garden hoses and sprinklers to intelligent automated systems that schedule watering based on weather forecasts and cistern water levels. |

|

The green roof is well covered by dense, attractive vegetation which helps maintain its stormwater treatment function and aesthetic value (Photo Source: Earth Rangers Centre)[5] |

|

| Protective layers |

May be one or two layers; designed to protect the roof deck from water damage, including a waterproofing membrane, a root barrier that protects the water-proofing membrane from root penetration and degradation by microbial activity. |

|

Tips to Preserve Basic BMP Function[edit]

- To avoid over-compaction of the filter media, any maintenance tasks involving foot traffic on the filter bed should not be performed during wet weather.

- Pavers or walkways should be placed at roof access locations and along primary paths to facilitate access and avoid walking on planted portions during inspection and maintenance work.

- To perform installation, maintenance or repair work, do not use sharp tools, lawn staples and stakes which can damage the drainage layer, root barrier and water-proofing membrane. All sharp pieces of metal and fasteners should be removed from the media area with care.

- For green roofs with succulents (e.g., sedum) as vegetation cover, trim off top stems annually in the spring during the first two years of establishment and leave on the growing media surface to encourage colonization or purchase and spread fresh cuttings.

- Transplant vegetation that is established in the vegetation free perimeter areas to supplement plantings on the filter bed if species are appropriate (See appropriate Green Roof Plants here).

- Pruning of mature trees should be performed under the guidance of a Certified Arborist.

- Establish procedures and timing for irrigation system startup and winterization to avoid damage to system components from freezing.

- Routinely check that the automated irrigation systems is free of damage and delivering water evenly to vegetated areas.

- For green roofs with automated irrigation systems using municipal/drinking water, schedule watering to occur at night or early in the morning to minimize the loss of water to evaporation;

- For green roofs with automated irrigation systems using cistern water, irrigating during the day when evaporation rate is high will make greater use of stored rainwater, thereby freeing up more storage in the system for the next rain storm and helping to reduce site runoff volume.

Rehabilitation & Repair[edit]

Table below provides guidance on rehabilitation and repair work specific to green roofs organized according to BMP component.

| Component | Problem | Rehabilitation Tasks |

|---|---|---|

| Growing Media | Eroded growing media area ≥ 30 cm in length or other damage is present |

|

| Surface ponding remains for > 3 hours after the end of a storm event because water does not infiltrate through the growing media |

| |

| Surface ponding remains for > 3 hours after the end of a storm event because the drainage layer is clogged. |

| |

| Vegetation |

Plants are not thriving and [[Green roof media|Growing Media] is low in organic matter (< 3 %) or available phosphorus (< 2.2 mg/kg) |

|

| Overflow outlets |

Surface ponding remains for > 3 hours after the end of a storm event because overflow outlet is obstructed. |

|

| Irrigation system |

Distribution line, fitting or sprinkler nozzle is leaking, damaged or misaligned. |

|

| Protective Layers |

Water-proofing membrane has reached 40 years of age and is due for replacement. |

|

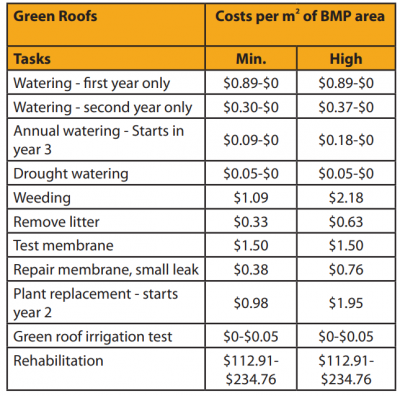

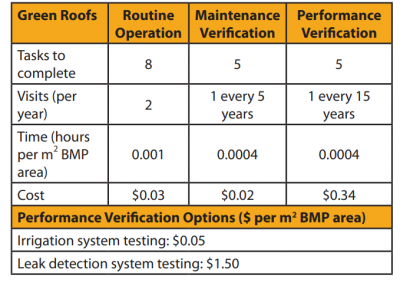

Inspection Time Commitments and Costs[edit]

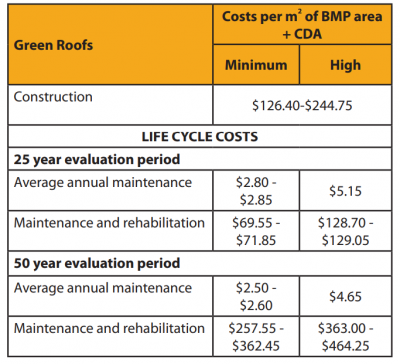

Estimates are based on an extensive green roof with 15 cm of growing medium, irrigation and water-proofing membrane with leak detection system; estimates for other combinations of these variables are described in the Low Impact Development (LID) Stormwater Management Practice Inspection and Maintenance Guide

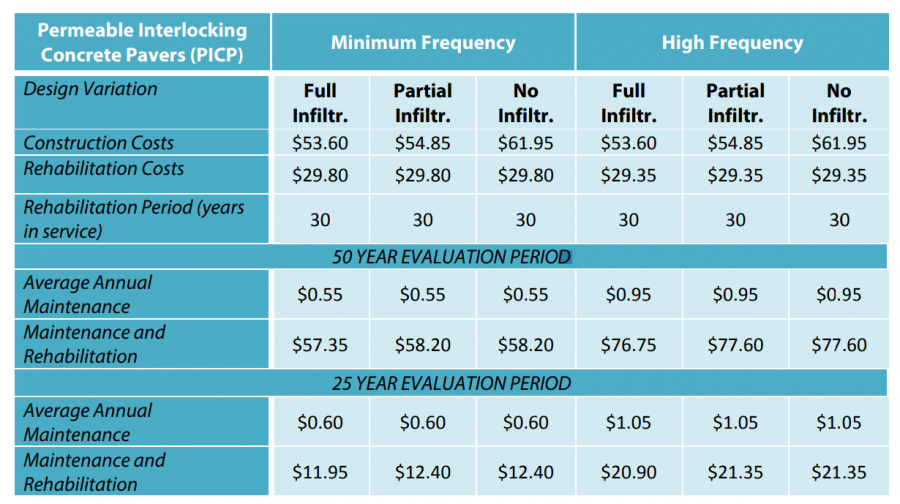

Estimates of the life cycle costs of inspection and maintenance have been produced using the latest version of the LID Life Cycle Costing Tool for three design variations (full infiltration, partial infiltration and no infiltration) to assist stormwater infrastructure planners, designers and asset managers with planning and preparing budgets for potential LID features.

Assumptions for the above costs and the following table below are based on the following:

- Design variations for permeable pavements can be broken down into three main categories:

- Full Infiltration design, where the pavement drains through infiltration into the underlying subsoil alone (i.e., no sub-drain);

- Partial Infiltration design, where drainage is through the combination of a subdrain and infiltration into the underlying subsoil (i.e., with a sub-drain); or,

- No Infiltration (i.e., filtration only design) that includes an impermeable liner between the base of the BMP and the underlying native sub-soil, where drainage is through a sub-drain alone (i.e., with a sub-drain and impermeable liner).

- For permeable pavements it is assumed that rehabilitation of the pavement surface will be needed once the BMP reaches 30 years of age in order to maintain surface drainage performance at an acceptable level. Included in the rehabilitation costs are (de)mobilization costs, as equipment would not have been present on site.

- Design costs were not included in the rehabilitation as it was assumed that the original LID practice design would be used to inform this work. The annual average maintenance cost does not include rehabilitation costs and therefore represents an average of routine maintenance tasks, as outlined in Table Permeable Pavements: Key Components, Descriptions and Routine I&M Requirements, above. All cost value estimates represent the NPV as the calculation takes into account average annual interest (2%) and discount (3%) rates over the evaluation time periods.

- The costing presented in this section is specific to permeable interlocking concrete pavers (PICP), as defined in the Tool. This product has been selected for costing due to its popularity and well understood maintenance needs.

- For all permeable pavement design variations, the CDA has been defined as 2,000 m2 of which 1,000 m2 is impermeable pavement draining to the pavers, and 1,000 m2 is permeable pavement. The impervious area to pervious area ratio (I:P ratio) used to size the BMP footprint is 1:1, which is in accordance with recommendations in the LID SWM Planning and Design Guide (CVC & TRCA, 2010).

- The Full Infiltration design does not include a sub-drain and assumes a native sub-soil infiltration rate of 20 mm/h. The base granular reservoir is 350 mm deep and is capable of storing runoff from a 61 mm rain event over the CDA. A monitoring well is included for inspection purposes.

- The Partial Infiltration design includes a sub-drain and assumes a native sub-soil infiltration rate of 10 mm/h. The base granular reservoir is 350 mm deep and is capable of storing runoff from a 9 mm rain event before the stored volume reaches the perforated underdrain pipe located 50 mm above the native sub-soil. Although a flow restrictor is recommended to maximize infiltration, the cost of this feature is not included due to its relatively low cost.

- The No Infiltration design includes a sub-drain pipe installed on the bottom of the sub-surface water storage reservoir and an impermeable liner. All other features are the same as the Partial Infiltration design variation.

- Estimates of the life cycle costs of PICP permeable pavements in Canadian dollars per unit CDA ($/m2) are presented in the table below. LID Life Cycle Costing Tool allows users to select what BMP type and design variation applies, and to use the default assumptions to generate planning level cost estimates.

- Users can also input their own values relating to a site or area, design, unit costs, and inspection and maintenance task frequencies to generate customized cost estimates, specific to a certain project, context or stormwater infrastructure program.

- For all BMP design variations and maintenance scenarios, it is assumed that rehabilitation of the pavement surface will be necessary when the BMP reaches 30 years of age to maintain acceptable surface drainage performance. Rehabilitation of PICP pavements is assumed to typically involve the following tasks and associated costs:

- Remove pavers, bedding and joint fill and top 5 cm (2”) of base aggregate and replace with new material that meets design specifications

- Construction and Assumption inspection and testing associated with rehabilitation work to confirm that materials meet design specifications and installation is acceptable, including compaction and surface infiltration rate testing.

Notes:

- Estimated life cycle costs represent NPV of associated costs in Canadian dollars per square metre of CDA ($/m2).

- Average annual maintenance cost estimates represent NPV of all costs incurred over the time period and do not include rehabilitation costs.

- Rehabilitation cost estimates represent NPV of all costs related to rehabilitative maintenance work assumed to be needed after 30 years in service, including those associated with inspection.

- Full Infiltration design life cycle costs are lower than Partial and No Infiltration designs due to the absence of a sub-drain to construct, inspect and routinely flush.

- Rehabilitation costs for Full Infiltration designs are estimated to be 54.8% to 55.6% of the original construction costs for High and Minimum Recommended Frequency maintenance program scenarios, respectively.

- Rehabilitation costs for Partial Infiltration designs are estimated to be 53.5% to 54.3% of the original construction costs for High and Minimum Recommended Frequency maintenance program scenarios, respectively.

- Rehabilitation costs for No Infiltration designs are estimated to be 47.4% to 48.1% of the original construction costs for High and Minimum Recommended Frequency maintenance program scenarios, respectively.

- Maintenance and rehabilitation costs over a 25 year time period for the Minimum Recommended maintenance scenario are estimated to be 22.3%, of the original construction costs for Full Infiltration design, 22.6% for Partial Infiltration design, and 20.0% for No Infiltration design.

- Maintenance and rehabilitation costs over a 25 year time period for the High Frequency maintenance scenario are estimated to be: 39.0% of the original construction costs for Full, 38.9% for Partial Infiltration designs, and 34.5% for No Infiltration designs.

- Maintenance and rehabilitation costs over a 50 year time period for the Minimum Recommended Frequency maintenance scenario are estimated to be approximately: 1.07 times the original construction cost for Full, 1.06 times the original construction costs for Partial Infiltration designs, and 93.9.% the original construction cost for No Infiltration designs.

- Maintenance and rehabilitation costs over a 50 year time period for the High Frequency maintenance scenario are estimated to be approximately: 1.43 times the original construction cost for Full, 1.41 times the original construction costs for Partial Infiltration designs, and 1.25 times the original construction cost for No Infiltration designs.

- ↑ 1.0 1.1 1.2 1.3 1.4 1.5 TRCA. 2018. Fact Sheet - Inspection and Maintenance of Stormwater Best Management Practices: Green Roofs. https://sustainabletechnologies.ca/app/uploads/2018/02/Green-Roofs-Fact-Sheet.pdf

- ↑ Construction Canada. 2012. Waterproofing considerations for green roofs. Photo source: Detec Systems. 1 March 2012. Accessed August 8 2022. https://www.constructioncanada.net/waterproofing-considerations-for-green-roofs/2/

- ↑ O’Connell Landscape. 2010. FROM THE DRAWING BOARD: MILL VALLEY & CORTE MADERA PLANTINGS. Authored 13 January 2010. Accessed 08 August 2022. https://oclandscape.com/ocblog/from-the-drawing-board-mill-valley-corte-madera-plantings/

- ↑ ASTM International. 2015. Standard Guide for Selection, Installation, and Maintenance of Plants for Green Roof Systems. Designation: E 2400 – 06. http://hydro.engr.scu.edu/files/green_roof/ASTM_E2400-06.pdf

- ↑ Earth Rangers. n.d. What is the Green Roof? Accessed 08 August 2022. http://www.ercshowcase.com/building-envelope/green-roof/

- ↑ Vegetal i.D. n.d. Green Roof Irrigation. Accessed May 10 2022: https://www.vegetalid.us/green-roof-technical-resources/extensive-green-roof-design-guide/270-green-roof-irrigation.html

- ↑ TRCA. 2016. Low Impact Development Stormwater Management Practice Inspection and Maintenance Guide. Prepared by the Sustainable Technologies Evaluation Program. Vaughan, Ontario. https://sustainabletechnologies.ca/app/uploads/2016/08/LID-IM-Guide-7.4-Permeable-Pavements.pdf