Difference between revisions of "Permeable pavements: Construction"

| (11 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

Add | Add your content here !! | ||

==Construction Tasks Table== | ==Construction Tasks Table== | ||

| Line 10: | Line 10: | ||

!style="background: white; color: darkcyan"|Porous<br> Concrete | !style="background: white; color: darkcyan"|Porous<br> Concrete | ||

|- | |- | ||

| rowspan=" | | rowspan="6" style="text-align: center; 1style="background:darkcyan; color:white"|Pre-Construction || Design Verification and Site Walk-through|| style="text-align: center;" | x || style="text-align: center;" | x || style="text-align: center;" | x | ||

|- | |- | ||

| | | LID Construction Notes|| style="text-align: center;" | x || style="text-align: center;" | x || style="text-align: center;" | x | ||

|- | |- | ||

| | | Tendering and Contract|| style="text-align: center;" | x || style="text-align: center;" | x || style="text-align: center;" | x | ||

|- | |- | ||

| | | Communication, Inspection Plan and Utilities Coordination||style="text-align: center;" | x || style="text-align: center;" | x || style="text-align: center;" | x | ||

|- | |||

| Erosion and Sediment Control Measures||style="text-align: center;" | x || style="text-align: center;" | x || style="text-align: center;" | x | |||

|- | |||

| Mobilization, Access, Staging, and Perimeter Controls||style="text-align: center;" | x || style="text-align: center;" | x || style="text-align: center;" | x | |||

|- | |- | ||

| rowspan="4" style="text-align: center;"| Excavation and <br> Mass Grading ||Clearing and Grubbing|| style="text-align: center;" | x || style="text-align: center;" | x || style="text-align: center;" | x | | rowspan="4" style="text-align: center;"| Excavation and <br> Mass Grading ||Clearing and Grubbing|| style="text-align: center;" | x || style="text-align: center;" | x || style="text-align: center;" | x | ||

| Line 44: | Line 49: | ||

| Bedding layer || style="text-align: center;" | x || || | | | Bedding layer || style="text-align: center;" | x || || | | ||

|- | |- | ||

| rowspan=" | | rowspan="7" style="text-align: center;"| Finishing Grades || Placement and Finishing || | || style="text-align: center;" | x || style="text-align: center;" | x | ||

|- | |- | ||

| Paver Installation|| style="text-align: center;" | x || | | Paver Installation|| style="text-align: center;" | x || | ||

| Line 56: | Line 61: | ||

| Curbing (if applicable) || style="text-align: center;" | x || style="text-align: center;" | x || style="text-align: center;" | x | | Curbing (if applicable) || style="text-align: center;" | x || style="text-align: center;" | x || style="text-align: center;" | x | ||

|- | |- | ||

| Stabilizing Contributing Drainage Area || style="text-align: center;" | x || style="text-align: center;" | x || | | | Stabilizing Contributing Drainage Area || style="text-align: center;" | x || style="text-align: center;" | x || style="text-align: center;" | x | ||

|- | |- | ||

| As-built | | rowspan="3" style="text-align: center;"| Post-Construction || As-built Surveys || style="text-align: center;" | x || style="text-align: center;" | x || style="text-align: center;" | x | ||

|- | |- | ||

| | |Address Deficiencies || style="text-align: center;" | x || style="text-align: center;" | x || style="text-align: center;" | x | ||

|- | |- | ||

| | | Final Certification || style="text-align: center;" | x || style="text-align: center;" | x || style="text-align: center;" | x | ||

|} | |||

==Pre-Construction== | |||

{{:Design verification and site walk-through}} | |||

{{:LID construction notes}} | |||

{{:Construction: tendering and contract}} | |||

{{:Construction: communication, inspection plan, and utilities coordination}} | |||

{{:Construction: erosion and sediment control measures}} | |||

'''ESC Inspection and Maintenance'''<br> | |||

{{:Construction: mobilization, access, staging, and perimeter controls}} | |||

==Excavation and mass grading== | |||

===Excavation and mass grading: clearing and grubbing=== | |||

{{:Construction: clearing and grubbing}} | |||

===Excavation and mass grading: excavation=== | |||

{{:Construction: excavation and rough grade}} | |||

===Excavation and mass grading: subgrade=== | |||

{{:Construction: subgrade}} | |||

===Excavation and mass grading: verification of grading/survey=== | |||

{{:Construction: final excavated grade and verification}} | |||

==Backfill Granular, Utilities and Pipes== | |||

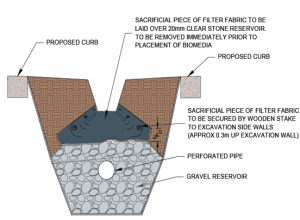

===Backfill granular, utilities and pipes: geotextiles=== | |||

{{:Geotextiles: Installation}} | |||

===Backfill granular, utilities and pipes: impermeable liner=== | |||

{{:Impermeable liners: Installation}} | |||

===Backfill granular, utilities and pipes: underdrains=== | |||

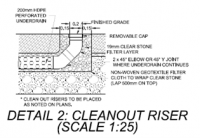

{{:Underdrains: Installation}} | |||

===Backfill granular, utilities and pipes: overflows=== | |||

{{:Overflow: Installation}} | |||

===Backfill granular, utilities and pipes: monitoring wells=== | |||

{{:Monitoring wells: Installation}} | |||

===Backfill granular, utilities and pipes: sub-base reservoir=== | |||

{{:Construction: sub-base reservoir}} | |||

===Backfill granular, utilities and pipes: base course=== | |||

{{:Construction: base course}} | |||

===Backfill granular, utilities and pipes: filter layer=== | |||

{{:Construction: filter layer}} | |||

===Backfill granular, utilities and pipes: bedding layer=== | |||

{{:Construction: bedding layer}} | |||

==Finishing Grades== | |||

===Finishing grades: placement and finishing=== | |||

{{:Construction: }} | |||

===Finishing grades: paver installation=== | |||

{{:Construction: }} | |||

===Finishing grades: tamping=== | |||

{{:Construction: tamping}} | |||

===Finishing grades: joint cutting=== | |||

{{:Construction: joint cutting}} | |||

===Finishing grades: joint aggregate=== | |||

{{:Construction: joint aggregate }} | |||

===Finishing grades: curbing=== | |||

{{:Construction: curbing}} | |||

===Finishing grades: pre-treatment and inlet=== | |||

{{:Construction: pretreatment and inlet}} | |||

===Finishing grades: stabilizing contributing drainage area=== | |||

{{:Construction: stabilizing contributing drainage area}} | |||

==Post-construction== | |||

===Post-construction: as-built surveys=== | |||

{{:As-built surveys}} | |||

===Post-construction: address deficiencies=== | |||

{{:Addressing deficiencies}} | |||

===Post-construction: final certification=== | |||

{{:Final Certification}} | |||

Latest revision as of 13:18, 27 July 2022

Add your content here !!

Construction Tasks Table[edit]

| Construction Stage | Construction Task | Permeable Interlocking Concrete Pavers |

Porous Asphalt |

Porous Concrete |

|---|---|---|---|---|

| Pre-Construction | Design Verification and Site Walk-through | x | x | x |

| LID Construction Notes | x | x | x | |

| Tendering and Contract | x | x | x | |

| Communication, Inspection Plan and Utilities Coordination | x | x | x | |

| Erosion and Sediment Control Measures | x | x | x | |

| Mobilization, Access, Staging, and Perimeter Controls | x | x | x | |

| Excavation and Mass Grading |

Clearing and Grubbing | x | x | x |

| Excavation | x | x | x | |

| Subgrade | x | x | x | |

| Verification of Grading/Survey* | x | x | x | |

| Backfill Granular, Utilities and Pipes |

Geotextile (if applicable) | x | x | x |

| Impermeable Liner (if applicable) | x | x | x | |

| Underdrain (if applicable) | x | x | x | |

| Overflow or Overflow Drain (if applicable) | x | x | x | |

| Monitoring Well (if applicable) | x | x | x | |

| Sub-base Reservoir (if applicable) | x | x | x | |

| Base Course | x | x | x | |

| Filter Layer (if applicable) | x | x | x | |

| Bedding layer | x | |||

| Finishing Grades | Placement and Finishing | x | x | |

| Paver Installation | x | |||

| Tamping | x | x | x | |

| Joint Cutting | x | |||

| Joint Aggregate | x | |||

| Curbing (if applicable) | x | x | x | |

| Stabilizing Contributing Drainage Area | x | x | x | |

| Post-Construction | As-built Surveys | x | x | x |

| Address Deficiencies | x | x | x | |

| Final Certification | x | x | x |

Pre-Construction[edit]

When the design is 90% complete, the project manager (PM) should conduct a walk-through of the site to verify that the designs match site conditions. This site walk-through is a critical step in the transition from design to construction and helps the project manager plan for future pre-bid or pre-construction meetings. Think carefully about how a contractor will be able to build the LID practice. At this stage, determine if the design drawings and construction notes address specific LID construction requirements, and determine whether they contain inaccuracies or are missing detail. The table below identifies details key points and considerations for the walk-through.

| Verification point | Key considerations |

|---|---|

| Adjacent land uses |

|

| Contributing and receiving drainage areas |

|

| Seasonal maintenance operations | |

| Location of LID features |

|

| Existing and planned infrastructure/utilities |

|

| Property boundaries and building foundations |

|

| Natural heritage features and existing vegetation |

|

| Access, sequencing, staging, and constructability |

|

LID construction notes[edit]

LID design drawings need detailed construction notes within the design drawings. These notes should include:

- sequencing and staging areas

- material specifications

- testing requirements

- installation procedures

- elevations and invert details for inlet, outlet, and overflow features

- grading details for conveyance features

- erosion and sediment control requirements

- inspection and maintenance responsibilities during construction and prior to assumption

The last two bullets require further comment. LID facilities are most vulnerable to sedimentation and clogging during their own construction and construction of adjacent and connected lands. LID construction contracts should specify a sufficient combination of ESC measures and inspection and maintenance of the LID facility during the construction and assumption phases to ensure that it will function without remediation. Contracts for larger-scale projects, e.g., where the LID facility in question is part of a road reconstruction project or subdivision development, should contain clear terms covering responsibilities for keeping sediment from entering newly constructed LID features and removing it if necessary.

The project contract and tendered drawings, including details, notes, ESC requirements, material specifications, and testing requirements should align. Given that most standard contract templates do not include wording specific to LID construction, considerations for LID can be placed under special provisions within the contract.

Details within the drawings and contract should also be accurately reflected in the tender bid form. A detailed bid form that reflects the entirety of the work allows contractors to deliver accurate bids, lessens the likelihood of project shortcuts, and helps to ensure transparency amongst bids. Ultimately, clear bid pricing reduces the potential for misunderstandings and conflicts and attracts experienced contractors.

Minimum contractor requirements[edit]

Many contractors are unfamiliar with building LID practices, so project managers should consider minimum contractor requirements. Consider mandating contractor training, attendance at pre-bid meetings, LID project references, and bid bond insurance as prerequisites.

After securing a contractor, a pre-construction meeting between the project manager, project engineer, and contractor will facilitate an efficient job site and reduce the potential for miscommunication. These meetings should cover:

- LID design details and construction notes

- material specifications, inspections, and chain-of-custody

- access routes and storage areas

- protection of LID practices: phasing, ESC, and perimeter fencing

- equipment requirements and recommendations

- verification of field changes

- plant establishment and warranty-period maintenance

- ownership and assumption protocols

- project inspection plan

- verification processes for field changes to the design and material substitutions

The table below expands upon the bullets above and provides helpful guidance on communication topics at the pre-construction meeting. Given the lead-up time needed for testing requirements of specified materials, these discussions should occur soon after the contract is awarded, ideally 2 months prior to project construction.

| Communication topic | Guidance |

|---|---|

| LID design details and construction notes |

|

| Material specifications, inspections, and chain-of-custody |

|

| Access routes and storage areas |

|

| Protection of LID practices during construction: phasing, ESC, and perimeter controls |

|

| Equipment requirements and recommendations |

|

| Verification of field changes |

|

| Plant establishment and warranty-period maintenance |

|

| Ownership and assumption protocols |

|

| Project inspection plan |

|

Inspection plan[edit]

The inspection and maintenance page gives detailed guidance on how to conduct construction inspections for LID practices. Generally, construction inspections should be continuous as the work progresses. If this isn’t possible, critical inspection points are:

- site preparation

- excavation

- installation of pipes, granular, and biomedia

- finishing grades

- surface treatment installation: pavers, plants, porous concrete, etc.

- after rain events (see ESC inspection and maintenance)

- whenever sub-contractors or utilities begin work (hand-off points)

The last element—inspection of sub-contractors—requires further comment. For example, if a sub-contractor is installing the curbing, they need to understand the purpose of the curbing and curb cuts, i.e., that they are meant to direct water into the LID facility, not to the closest catch basin. Without this knowledge, the sub-contractor may mistakenly build the curbs as they usually do: to direct water into a catchbasin.

Utilities coordination[edit]

Similarly, if the LID practice is in close proximity to sub-surface utilities, the utility owner may use their own contractors to perform related work. If this is the case, these sub-contractors must also be made aware of the LID practice’s purpose, how compaction affects performance, keeping the LID practice clear of excavated dirt and generally how their work could impede the construction and performance of the LID practice. In general, communication between the contractors, project managers, and project engineers should be frequent and open.

STEP’s Erosion and Sediment Control Guide contains detailed guidance on the design, installation, inspection, maintenance, and decommissioning of ESC measures. This section gives practical advice on structural and non-structural ESC for contractors, inspectors, and those who are new to construction and ESC practices.

Establish required perimeter controls, including erosion and sediment control (ESC) measures, prior to construction and adjust accordingly during construction. ESC measures come in two basic types: structural ESC, which slows and holds runoff from the disturbed area, dissipating erosive forces, promoting ponding, and allowing suspended particles to settle out; and non-structural ESC, which primarily minimizes the exposure time of stripped soils.

For non-structural ESC measures, be sure to:

- Stage clearing and grubbing to minimize exposure of stripped soils.

- Watch the weather and adjust plans accordingly.

- Manage and demarcate heavy equipment routes away from LID practices.

- Use simple, common-sense methods, such as scarifying exposed soils perpendicular to the grade to prevent the development of rills.

- Create and use a pollution prevention plan for fuels or solvents.

Generally, all exposed soils that are not being actively worked on must have temporary erosion protection or permanent cover within 7 days for slopes 3:1 or greater and 14 days for slopes 3:1 or lesser. This should apply to all exposed soil areas year-round and until the site is stabilized.

The table below gives guidance on common mistakes made when installing structural ESC measures.

| Structural ESC measure | Do | Don't | (Pass) Photo Example | (Fail) Photo Example |

|---|---|---|---|---|

| Sediment fencing |

|

|

||

| Inlet controls |

|

|

||

| Stockpiles |

|

|

||

| Protecting features during construction, including using sacrificial filter fabric |

|

|

ESC Inspection and Maintenance

In tandem with installation of ESC measures, setting up access and staging areas is one of the first steps in any construction project. Perimeter controls such as construction fencing are often combined with silt fencing. Safety fencing may be needed to restrict public access to the site, especially if the site sees lots of pedestrian traffic. Together, construction fencing and structural ESC measures should demarcate:

- the limits of construction

- heavy equipment routes

- equipment and material storage areas

- LID practice footprints

- natural heritage features

- access areas

Construction steps

- Install perimeter fencing/silt fence in alignment with design drawings and ESC plan.

- Demarcate staging and access points with fencing or surface markings in alignment with design drawings.

Key inspection points

- Ensure perimeter fencing and access/staging areas are in alignment with design drawings.

Mistakes to avoid

- Departing from the plan to stage and limit access points, material storage areas, and equipment storage areas

- Installing inadequate perimeter controls, e.g. inadequate sediment fencing or construction fencing

Excavation and mass grading[edit]

Excavation and mass grading: clearing and grubbing[edit]

Clearing and grubbing is the stripping of vegetation and topsoil prior to excavation and rough grading within designated areas.

Construction steps

- Clear trees, large shrubs, stumps, etc. (grubbing).

- Use appropriately sized machinery (e.g. a mini-excavator) to strip sod and ground-level vegetation (clearing).

- Stockpile materials within designated areas if necessary. If the materials are being hauled offsite, stripped materials ideally would go straight into the back of a dump truck.

- Secure stockpiles with appropriate erosion and sediment control (ESC) measures if the material must be stored before hauling offsite or will be reused.

Key inspection points

- Structural ESC measures are in place before clearing and grubbing begin.

- Natural heritage features, including trees, and construction limits are clearly marked and respected by the contractor.

- Contractor cleared and grubbed only within designated areas and according to the phasing plan.

Mistakes to avoid

- clearing more area than is needed

- insufficient marking of areas to be protected

- stockpiling materials without ESC controls or for extended periods of time

- leaving heavy equipment in the facility’s footprint

- making excessive passes with heavy equipment in the LID practice’s footprint without scouring soil afterward

Excavation and mass grading: excavation[edit]

Excavation to the specified depths in the drawings is critical to the LID feature’s future performance. It also requires heavy machinery which, if used incorrectly, can compact soils and lower their native infiltration rates.

Construction steps

- Mark out the limit of excavation.

- Use predefined access routes to move heavy equipment.

- Cut and stabilize access and staging areas.

- Cut and stabilize channels and slopes.

- Excavate the LID feature from the outside-in whenever possible. A standard excavator (10-45 tons) has a longer reach than mini (<6 tons) or midi excavators (6-10 tons) and can be the best choice despite its weight, since it may not need to enter into the facility’s footprint to complete the job. However, a mini excavator would be the best choice if entry into the LID feature’s footprint is necessary.

- Excavate to within 100 mm of the final grade.

- Check grades with appropriate equipment (transit levels, etc.).

- Stockpile materials in a designated area if it must be stored before hauling.

Key inspection points:

- Confirm the limit of excavation.

- Use of excavation equipment specified in the contract, in the required manner (from the outside in, with a mini excavator, etc.).

- Confirm excavated rough grade and final grade prior to backfilling using survey equipment

- Use of toothed bucket and scouring the bottom of practice if applicable

- If appropriate, measure compaction using a cone penetration test or a cone penetrometer

- If appropriate, field verify infiltration rates at excavated bottom of practice using Guelph permeameter or double ring infiltrometer

Mistakes to avoid:

- making too many passes with heavy machinery within the LID footprint.

- leaving heavy machinery within the LID’s footprint (for breaks, lunch, overnight, etc.)

- using the wrong equipment

- over excavating

- smearing the bottom of the practice with the bucket, which can compact native soils

Excavation and mass grading: subgrade[edit]

Excavation and mass grading: verification of grading/survey[edit]

LID designs typically have specific grading requirements. Verifying depths and slopes is critical for the optimal performance of the facility. For example, if the design calls for a channel with a 1% slope, the channel may not function as designed if it has a 2% slope instead.

Excavation to the sub-grade will differ depending on whether the design is for a full infiltration, partial infiltration, or no infiltration LID system. If it’s a full infiltration or partial infiltration practice, the sub-grade should be as level as possible to promote even infiltration across the facility’s footprint. For no infiltration designs, excavate sub-grade slopes to the design grade in the direction of the underdrain, typically 1 to 2%.

As with all infiltrating LID practices, avoid compaction of sub-grade soils whenever possible. However, depending on the design and the local municipality, compaction of the sub-grade may be required for permeable pavement LIDs.

Construction steps

- Excavate the final 100 mm, to the final design grade, using appropriate equipment. This is often done with hand tools.

- Confirm excavation depths and slopes using appropriate equipment (transit levels, global navigation satellite systems, etc.)

Key inspection points

- Confirm final excavated depths and slopes.

Mistakes to avoid

- “eye-balling” depths and slopes

Backfill Granular, Utilities and Pipes[edit]

Backfill granular, utilities and pipes: geotextiles[edit]

Geotextiles are filter fabrics that can be installed to separate dissimilar soils and prevent the migration of materials. Geotextiles are recommended for installation at the bottom and side limits of the LID feature and should be implemented at the discretion of the engineer.

Construction Steps:

- Roll out fabric on the flattened sub-grade surface.

- Provide a minimum overlap of 300 mm between adjacent lengths of geotextile. If the manufacturer specifies a greater overlap, follow the manufacturer’s specification.

- Secure fabric in place with stakes along the edge of the sub-grade surface and where lengths of fabric overlap.

- Provide 500 mm of excess at the ends of each length of fabric. Fold excess materiel on top of the infiltration medium/choker course once installed.

- Provide cuts for trees and shrubs where appropriate.

- Assess on-site conditions to ensure that the tensile, tear, and puncture strength ratings of the geotextile are suitable for expected structural loads (e.g. traffic). If not properly considered, geotextiles can be adversely impacted by loading from adjacent infrastructure uses.

Key Inspection Points:

- Geotextile is clean and free of damage.

- Geotextile delivered to the site matches the design specifications and is approved by the engineer prior to installation.

- Sufficient overlap is provided between lengths of fabric.

- Geotextiles have been applied as per the manufacturer’s guidelines.

- Structural considerations for geotextiles have been made when applied adjacent to infrastructure and the geotextile can handle expected structural loads.

- Class II geotextiles conform to OPSS 1860.

Mistakes to Avoid:

- Wrinkles in the fabric: Follow the manufacturer’s procedure for installation to ensure geotextiles lie smooth on sub-grade.

- Unnecessary application of geotextile: Mixing of media is negligible where structural loads are not expected, so geotextile does not need to be applied. Also, geotextiles should not be used where root growth is encouraged to penetrate different layers of media.

Backfill granular, utilities and pipes: impermeable liner[edit]

Impermeable liners can be applied when LID features are not intended to infiltrate runoff into the underlying soil. They protect building foundations or other subsurface infrastructure. They also prevent infiltration through contaminated soils. Where building foundations next to the LID feature are not waterproofed, liners can be used to protect adjacent infrastructure.

Construction Steps:

- Compact 30 – 50 mm of sand over the soil onto which the membrane will be installed to protect against punctures. Alternatively, a geotextile can be used in the place of sand.

- Place lengths of liner on the bed of the facility as per the manufacturer’s specifications.

- Provide 150 mm of overlap between adjacent lengths of liner.

- Secure liner in-place and bond together the overlapping portions of liner as specified by the manufacturer.

- Seal a flange to the pipe and liner when pipes provide drainage from the practice.

- Compact sand or apply cushion fabric on top of the liner to protect against punctures.

Key Inspection Points:

- Liner matches design specifications.

- Liner installation procedures conform to manufacturer’s specifications.

- Minimum overlap between lengths of liner is achieved.

- Need for protection of building footprints and adjacent infrastructure confirmed through field verification of setbacks.

- Sand and/or geotextile are applied on both sides of the liner to protect against punctures.

- Lengths of liner are bonded together to ensure protection against groundwater penetration and contamination.

Backfill granular, utilities and pipes: underdrains[edit]

Underdrains are perforated pipes that collect subsurface water and convey water out of an LID facility once it reaches capacity. Their design is determined by the drainage requirements of the feature.

Construction Steps:

- Install the underdrain to grade with a consistent slope of 0.5% to 1.0%.

- Connect overflow risers with single-elbowed ‘y’ connections or 45° elbows.

- Situate maintenance risers where siltation is expected in drain lines (such as at junctions or where grade and direction changes occur), in accordance with the design drawings.

- Mark the locations of risers.

- Use video inspections to confirm that the interior of the underdrain remains free of debris after construction.

Key Inspection Points:

- Size, type, and material of the underdrain conforms to the design specifications.

- Underdrain is perforated prior to arrival on-site.

- Drain material is resistant to UV radiation and any chemicals in the soil and groundwater.

- Clean-outs are positioned correctly and spaced appropriately for the size of the underdrain.

- Any manual perforations are approved by the design or field engineer.

- Pipe grade matches design specifications.

- Tie-in locations to municipal sewers meet municipal specifications.

Mistakes to Avoid:

- Incorrect overflow risers – ensure single-elbowed ‘y’ connections or 45° elbows are used for overflow risers instead of ‘T’ connections.

- Incorrect drain size – confirm underdrain has an internal diameter greater than or equal to 200 mm to reduce freezing and allow cleaning and camera inspections.

- Potential for clogging – Remove sock from underdrain prior to installation or geofabric wrap. A choker course is recommended, instead, as field change.

For more information on the design of underdrains, such as materials and connections, see the page on underdrains linked above.

Backfill granular, utilities and pipes: overflows[edit]

Overflows are features of inline facilities and convey larger storm events out of the LID feature.

Construction Steps:

- Connect the overflow drain to the underdrain.

- Fit a metal, domed grate to the overflow.

- Install overflow pit to grade at the location specified in the contract documents.

Key Inspection Points:

- Overflow drain matches design specifications.

- Overflow pit is positioned at the maximum water surface elevation of the practice, as per the contract documents.

- Sufficient freeboard is provided between the overflow and inlet such that the inlet is not inundated by design storm flows.

- Overflow grate matches design specifications.

- Overflow grates located in high-traffic areas are screwed on or equipped with locks.

Mistakes to Avoid:

- Backflows: Ensure that backflows are avoided by confirming that inlet and overflow elevations match design specifications with surveys.

- Incorrect sequencing: Install overflow drain prior to backfilling with granular material and engineered soil.

- Incorrect grate material: Avoid using plastic overflow grates due to breakages and UV degradation.

Backfill granular, utilities and pipes: monitoring wells[edit]

Monitoring wells allow for measurement of water levels in the sub-surface components of LID practices. They are important for sampling procedures and ensuring that the LID feature are performing as intended.

Construction Steps:

- Install a cap stand at the required elevation to anchor the monitoring well.

- Wrap the perforated pipe with a geotextile sock (to prevent migration of soil into the well).

- Anchor the perforated pipe to the bottom of the LID feature.

- Install a lockable cap to the top of the standpipe to protect against vandalism.

- Install monitoring equipment (e.g., a level logger) if required.

Key Inspection Points:

- Pipe is perforated, rigid, and matches design specifications.

- Well is installed according to contract documents.

- Geotextile sock is wrapped around the perforated portion of the well.

Mistakes to Avoid:

- Incorrect sequencing: Ensure that standpipe is installed prior to backfilling with granular material.

Backfill granular, utilities and pipes: sub-base reservoir[edit]

Construction: sub-base reservoir

Backfill granular, utilities and pipes: base course[edit]

Backfill granular, utilities and pipes: filter layer[edit]

Backfill granular, utilities and pipes: bedding layer[edit]

Finishing Grades[edit]

Finishing grades: placement and finishing[edit]

Finishing grades: paver installation[edit]

Finishing grades: tamping[edit]

Finishing grades: joint cutting[edit]

Finishing grades: joint aggregate[edit]

Finishing grades: curbing[edit]

"'INSERT VIDEO FROM HAGGERT AVE: \\Hqcvcfs01\cvc2\Watershed Management\Integrated Water Management Implementation\Fletchers Creek SNAP\Haggert Ave Road Retrofit\3 - Photos\Construction Photos\Site Visit_20201120\Riverstone Construction Haggert Ave Inlet_F.mp4

It is very important to make sure that the contractor responsible for curb construction understands curb cut designs and elevations. This is often a new technique for contractors, and they may not understand the overall concept of water in the gutter line being directed behind the gutter.

Construction Steps:

- Place the right forms (rolled curve vs standard) in the inlet location.

- Pour concrete.

- Shape the inlet

- Add the river stone on top of the fresh concrete (if applicable)

- Provide sufficient curing time, according to (CSA, 2009)[1]

Key Inspection Points:

- Use of proper curb form by sub-contractor.

- Curb type aligns with design.

- Curb cut location, type and dimension aligns with design.

- Designated concrete wash out is in place and away from LID facility.

Mistakes to Avoid:

- Elevated curb cuts and reverse slopes (sloping from back of curb towards instead of depressing from gutter line towards the back).

- Wrong curb cut width size.

- Use of wrong curb form.

- Concrete wash out within or upstream of LID facility.

- Ensure curb granular base (granular A) does not spill over into LID infiltration area. If material spills over, remove as best as possible while still maintaining the 2:1 slope for curbing

- Lack of communication to concrete contractor or ready-mix driver explaining the function and importance of protecting the LID feature.

For more information on curb cuts, see these pages: Curb cuts, Curb cuts: Gallery and Bioretention: Streetscapes

Finishing grades: pre-treatment and inlet[edit]

Pre-treatment structures are most cost effective when they slow down incoming flows, collect sediment for easy clean out, and slowly release water to the bioretention facility mitigating erosion. Pretreatment structures/strategies can include curb cuts, Aggregates, proprietary devices like filters or hydrodynamic separators, vegetation, concrete sumps, membrane filters, overland flow sumps, etc.

Construction Steps:

- Installation of pretreatment features will vary based upon type. Similarly, installation timeline will range with type and could occur at excavation and mass grading, curb work or at finishing grade. Given pre-treatment features are typically integrated with the LID inlet coordination amongst multiple sub-contractors is sometime needed. The following details steps for various pre-treatment types:

- Vegetation: Follow the guidance shown below in the section “Plant Material Verification and Installation”

- Curbing: Follow the guidance shown above in the section “Curbing”.

- Aggregate: Follow the guidance shown above in the section “Stone reservoir”.

Proprietary pre-treatment device[edit]

- Excavate and prepare base for proprietary pre-treatment device according to design.

- Install proprietary pre-treatment device according manufacturer directions.

- Manufacturer representative may need to confirm proper installation and functioning through approved testing and inspection.

Key Inspection Points:

- Verify that the correct pre-treatment device (jellyfish filter, vegetation, curbing, etc.) is being installed.

- Verify that all components of the pre-treatment device are installed

- Verify correct size and location of pre-treatment device.

- Verify correct elevation, slope, and footing according to design

- Is it tied into the curb, downspout, or other inlet? Or could happen before the curbing?

- Wet weather performance check:

- Does it work?

- Is water entering the LID facility properly?

- Is sediment and debris accumulating?

- Is it dissipating erosive forces?

Mistakes to Avoid:

- Pre-treatment component parts are missing

- Grading/elevation errors that deviates from design

- Incorrect pipe inverts causing short circuiting

- Insufficient grade drop or slope into pre-treatment to ensure positive flow of water

- Improper grading from pre-treatment to LID feature inhibiting positive flow

- Insufficient sump depth to account for sediment and debris accumulation

- Using wrong concrete forms if concrete curbs are part of pre-treatment.

For more information about pre-treatment strategies and their design, visit these page(s): Pretreatment and Pretreatment features.

Finishing grades: stabilizing contributing drainage area[edit]

Similar to the plant material verification and installation task shown in Construction: plant material verification and installation page, any planting required to stabilize the contributing drainage area will need to meet the specifications and considerations shown in such page.

Additionally, if turf/grasses is required to stabilize the contributing drainage area, installation should be done as per the grower/nursery’s specifications and standards.

Post-construction[edit]

Post-construction: as-built surveys[edit]

Throughout the construction process, it is sometimes necessary to deviate from the intended design of LID features and adapt the design to on-site conditions. The completion of a post-construction as-built survey is a standard operating procedure for engineering projects that captures any changes made to the feature’s design during construction. For an example of municipal standards for as-built surveys, refer to the City of Toronto's Engineering Survey Standards for Consultants[2]

Survey Steps:

- Use the same datum as the pre-engineering survey.

- If a pre-engineering survey is not available, use a reference feature as the datum.

- Identify the type, diameter, and material of exposed utilities.

- Include data on critical feature elevations and existing utilities, such as:

- Inverts of newly installed pipe

- Vertical and horizontal bends in pipes

- Existing public utilities

- Existing private utilities

- New and existing structures (e.g., catchbasins, manholes, chambers, etc.)

Inspection Points:

- Datum matches the pre-engineering survey or selected reference feature.

- Data provided in as-built survey matches the as-built standards of the local municipality.

Post-construction: address deficiencies[edit]

Prior to passing responsibility to the landowner, contractors must ensure that any deficiencies in the LID feature’s construction are addressed. Keep in-mind what mistakes must be avoided during each construction task.

Post-construction: final certification[edit]

Final inspection requirements are in-place to ensure that a final site-wide inspection is performed and that mitigation can occur before the contractor is relieved of responsibility. Final certifications are performed by knowledgeable personnel, such as the design engineer, who are qualified to ensure that LID features are operating as intended. This stage is critically important, as it is the last opportunity for issues to be resolved before the property owner assumes responsibility of the practice. Four (4) levels of inspection exist for final inspections of LID infiltration and filtration practices. The level of inspection, or combination of tests, that is selected is dependent on the goals of the assessment and feasibility of each inspection. A substantial amount of guidance is available in Low Impact Development Certification Protocols: Bioretention Practices.[3]

Visual Inspection (Level 1)

This qualitative method is low cost and requires minimal effort to conduct. Visual inspection should be used as an initial step to determine if the LID practice is operating properly. Visual inspections can be performed during dry weather and wet weather to examine various aspects of LID performance, such as the following:

- draw-down time

- ponded water

- soil properties

- plant cover and plant health

- sedimentation

Surface Infiltration Capacity Testing (Level 2)

Level 2 includes the employment of quantitive methods of testing and data collection. These tasks are also cost-effective and can establish if the LID feature was built in conformance with the design specifications. Some level 2 tests include the following:

- soil sampling and testing

- elevation surveys

- infiltration testing

- synthetic runoff testing

Continuous Water Level Monitoring (Level 3)

Site infiltration rates can be measured with greater accuracy through continuous water level monitoring. This monitoring approach evaluates seasonal infiltration performance through the monitoring of temperature and groundwater levels. The following conditions and equipment are necessary for continuous water level monitoring:

- A perforated observation well

- A water level logger

- A rain gauge within 5 km of the site

Using rainfall and water level data can provide an understanding of drawdown times after variously sized storms.

Long-term Monitoring (Level 4)

High-intensity monitoring is a comprehensive but expensive approach to assessing peak flow reduction and water volume reduction during natural runoff events. These reductions can be quantified by completing a water budget during natural storm events, specifically through the measurement of inflow and outflow. Pollutant load reductions can also be quantified with the appropriate technology. Long-term monitoring is especially recommended if the LID feature that is the subject of the test is the first of its kind in its given jurisdiction, if geologic conditions pose a concern, or if the feature is being implemented to protect sensitive and significant natural features.

- ↑ CSA. 2009. A23.1-09/A23.2-09 (R2014). Concrete materials and methods of concrete construction/Test methods and standard practices for concrete. standard A23.1-09. https://www.csagroup.org/store/product/2420232/#:~:text=and%20specialty%20concretes.-,A23.,A%20sister%20standard%20%E2%80%93%20CSA%20A23

- ↑ City of Toronto. 2021. Engineering Survey Standards for Consultants. https://www.toronto.ca/wp-content/uploads/2017/11/98c7-ecs-specs-surveys-engsrv_survey_standards_for_consultant.pdf

- ↑ CVC. 2015. Low Impact Development Certification Protocols: Bioretention Practices. Version 1.0 . https://cvc.ca/wp-content/uploads//2021/07/2016-04-21-web-version-CVCbioretentionCertificationProtocols.pdf

- ↑ CVC. 2012. Low Impact Development Construction Guide. Version 1.0. Photo. https://cvc.ca/wp-content/uploads/2013/03/CVC-LID-Construction-Guide-Book.pdf