Porous Asphalt: Life Cycle Costs

Overview[edit]

Porous Asphalt is an alternative to traditional impervious pavements that allow stormwater to drain through them and into a storage reservoir below. Porous asphalt's performance and integrity is similar to that of other standard asphalt pavements. Similar to permeable pavers, porous asphalt has an underlying stone aggregate bed that provides drainage of incoming runoff and pluvial water. The benefit of porous asphalt in comparison to some other permeable pavements is that it doesn't require third party, proprietary components, nor specialized paving equipment for installation. [1]

Depending on the native soil properties and site constraints, the system may be designed for full infiltration, partial infiltration, or as a non-infiltrating detention and filtration only practice. They can be used for low traffic roads, parking, driveways, and walk ways, and are ideal where space for other surface BMPs is limited. Permeable pavement types include: • permeable interlocking pavers (concrete or composite materials) • grid systems (concrete or composite materials) • pervious concrete (poured-in-place or pre-cast) • porous asphalt • permeable articulating block/mat systems

For the sake of this page and associated costs/figures below the information found here relate to Porous Asphalt, for costs and information associated with Permeable pavements click here. STEP conducted life cycle costs estimates for each of permeable pavements 3 design configurations which can be viewed below. To design your own life cycle cost estimates that can be adapted to fit your project budget and unique development needs access the updated LCCT Tool here.

Design Guidance[edit]

Permeable pavers are ideal for sites with limited space and projects such as low traffic roads, parking lots, driveways and walkways. Components include: interlocking pavers, precast pervious slabs, cast in place surface, bedding course, and underground storage layer. Additional components include an underdrain to remove excess water and soil additives to enhance pollutant removal.

STEP recommendations:[edit]

- Bedding layer and joint filler should consist of clear stone and gravel rather than sand to prevent clogging.

- Granular materials should not be applied as anti-skid agents during winter because they can quickly clog the system.

- Winter maintenance practices should be limited to plowing, with de-icing salts applied sparingly.

- The slope of the permeable pavement surface should be at least 1% and no greater than 5%.

- The impervious land surrounding and draining onto the pavement should not exceed the area of the permeable pavement (1:1 / I:P ratio).

- Pervious surfaces should not drain onto the pavement.

- The storage layer must be sized to accommodate runoff from the pavement and any impermeable areas draining to it.

Tool defaults based on STEP recommendations:[edit]

- Maximum drainage area to surface area ratio of 1:1 (or 4:1 for roofs that contribute clean runoff to the practice)

- Default Bedding depth of 50 millimeters.

- Default Base depth of 100 millimeters.

- An underdrain (minimum 150 mm perforated pipe) is only needed when native soil infiltration is less than 15 mm/hr or infiltration is precluded.

Design Notes[edit]

- The tool calculates costs for new designs and includes costs for contractor overhead and profit, material, delivery, labour, equipment (rental, operating and operator costs), hauling and disposal. Mobilization and demobilization costs not included. The tool adds 10% contingency and additional overhead.

- Design and Engineering cost estimates are not calculated by the tool and must be supplied by the user.

- Unit costs are based on 2018 pricing; the tool automatically adds inflation. See the Assumptions sheet in the tool for further details.

- The cost of retrofitting is ~16% higher than the cost of new construction.

- Retrofit costs are included in the 'Costs Summary' section and can be added to the Total Construction Cost for increased accuracy.

- Retrofit costs are included in the 'Costs Summary' section and can be added to the Total Construction Cost for increased accuracy.

Note: Permeable Pavements (all 3 design scenarios): Assumes that replacement of pavers occurs at 8 years, and a full rehabilitation of the practice is performed at 30 years.

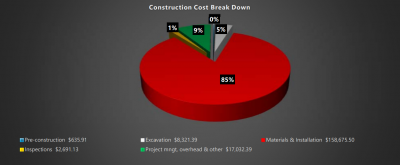

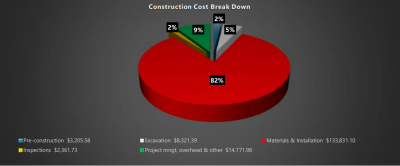

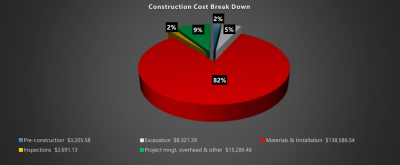

Construction Costs[edit]

Note: Please click on each image to enlarge to view associated construction cost results.

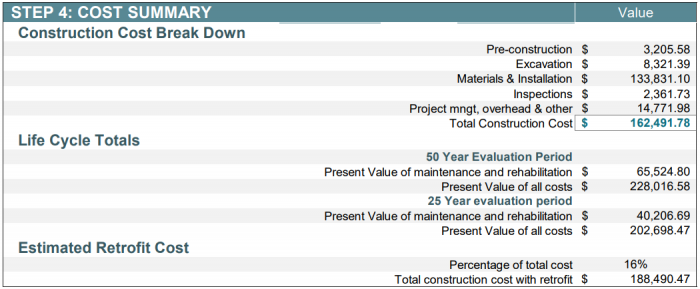

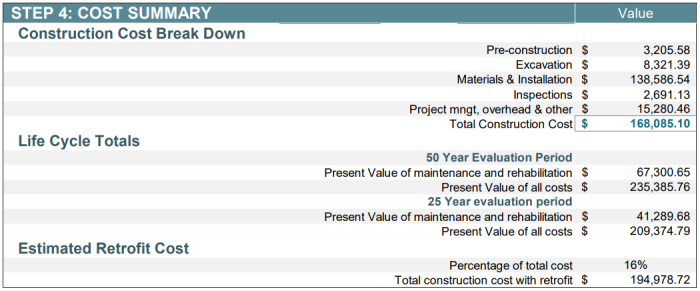

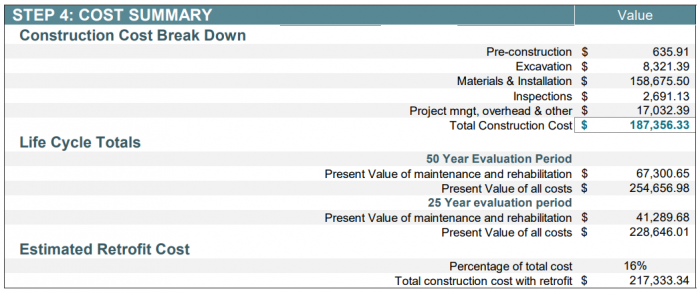

Above you can find a cost breakdown of a 1000m2 in three different configurations:

- Non-infiltrating/filtration only Permeable Pavement,

- Partial infiltration Permeable Pavement

- Full infiltration Permeable Pavement

As can be seen the greatest cost for this practice (regardless of configuration type) will be Material & Installation, which include costly components such as the, impermeable membrane/liner, the underdrain, the sub-base of 50mm clear stone, base of 19mm clear stone and the bedding pavers themselves.

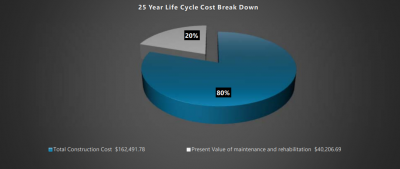

Life Cycle Costs[edit]

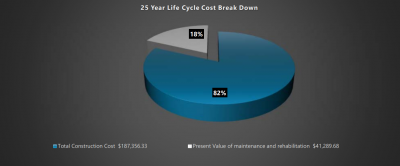

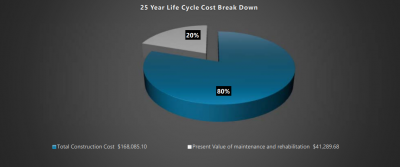

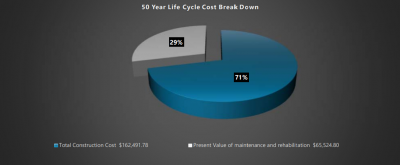

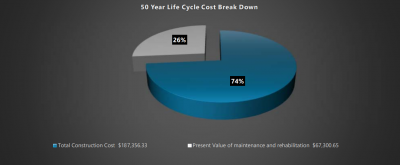

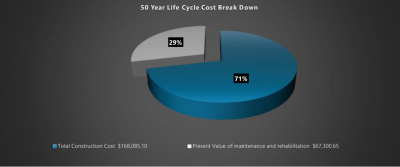

Below are both the capital and life cycle costs of the three bioretention configuration practices over a 25 and 50-year time horizon based on a detailed assessment of local input costs, maintenance requirements, rehabilitation costs and design scenarios relevant to Canadian climates. The costs of maintenance and rehabilitation (Life cycle costs) are set at "Present Value" of these activities in 2022.

Looking at the pie charts below for each configuration we can see that they are all relatively close to being the same cost with a variation of a few hundred dollars between each over both a 25 and 50-year time horizon. The percentage of the Full Infitlration configuration is greater than the other two due to the lesser cost of the overall installation for material and Installation, (no underdrains, no gravel storage layer or impermeable membrane, etc.).

25-Year life cycle cost break down[edit]

Note: Please click on each image to enlarge to view associated life cycle cost results.

50-Year life cycle cost break down[edit]

Note: Please click on each image to enlarge to view associated life cycle cost results.

Total Cost & Design Summary[edit]

As previously discussed the three Permeable pavement configurations total cost summary vary greatly dependent on whether you want your feature to possess full infiltration, no infiltration, or partial infiltration. In short the most expensive of these options is the Permeable Pavement: No infiltration option ($187,356.33 vs. $168,085.10 - partial infiltration and $162,491.78 - full infiltration). The same can be said for construction + associated retrofit costs with each configuration design ($217,333.34 vs. $194,978.72 - partial infiltration and $188,490.47 - full infiltration). This configuration costs more than the other two predominantly due to the addition of an over 1,100m2 Impermeable membrane (0.762 mm High Density Polyethylene-HDPE), which costs $24,181.47. This difference in price accounts for all three configurations possessing the exact same surface area footprint of 1,000m2. As a reminder, it is important to understand your site's surrounding native soil infiltration rate to ensure you are selecting the appropriate design and if your site is located within a WHPA or Pollution hotspot, thus requiring a non-infiltration practice such as the aforementioned configuration of a permeable pavement feature.

A final note regarding the accuracy of the LCCT. A follow up sensitivity analysis study was conducted by CVC & STEP back in 2019 to test the tool's accuracy. The analysis took designs from 6 completed projects (4 bioretention, 1 permeable pavement, and 1 infiltration trench), and ran them through the tool comparing construction costing results from the LCCT to actual construction costs for the projects. The accuracy target set for the tool was plus-or-minus 30% of actual construction costs.

The analysis found that the tool was on average (±14%) to actual construction costs[2]

Full Infiltration[edit]

Partial Infiltration[edit]

Non-Infiltrating/filtration only[edit]

References[edit]

- ↑ Speight, J.G., 2016. Asphalt materials science and technology (pp. 437-474). Butterworth-Heinemann is. https://link.springer.com/article/10.1557/mrs.2016.267#article-info

- ↑ Credit Vally Conservation (CVC). 2019. Life-cycle costing tool 2019 update: sensitivity analysis. Credit Valley Conservation, Mississauga, Ontario. https://sustainabletechnologies.ca/app/uploads/2020/04/LCCT-Sensitivity-Analysis_March2020.pdf