Salt

Overview[edit]

Between 5 and 7 million tonnes of salt is applied every year in Canada for winter maintenance of roads and other paved surfaces, making it one of the most ubiquitous contaminants in urban environments. Canadians spend over $1 billion in winter maintenance costs to clear snow/ice on public and private roads, parking lots and sidewalks, this includes the use and application of greater than 5 million tonnes of rock salt for both deicing and anti-icing operations (Hossain et al., 2015)[2]. While the use of salt is essential to ensure public safety, there is a growing concern regarding the large quantities of salt (mainly chloride ions), being released to the environment.

NaCl- is the most common de-icer applied for winter maintenance, comprised of 40% sodium and 60% chloride. Sodium chloride rock salt is often treated with liquid MgCl2 and CaCl2 to reduce the effective temperature range of salts. Liquid brines comprised of NaCl- , MgCl2 and CaCl2 or a combination of these products are increasingly being used on roads for anti-icing to help reduce the amount of rock salt used and lower overall operations costs.

Impacts on the Environment, Human Health and Built Infrastructure[edit]

While salt is needed to keep roads safe in the winter, it is highly corrosive and toxic to freshwater wildlife at relatively low concentrations. Some of the impacts of salt on infrastructure, human health and the environment include the following:

Freshwater wildlife[edit]

Just as we depend on air with the right makeup of oxygen, freshwater species – like fish, frogs, mussels, salamanders and zooplankton – need water with the right balance of chloride to survive. Having adapted to low levels of chloride in their habitats, increased levels begin to disrupt their basic functions – such as regulating their water content (osmoregulation) and breathing. Studies have shown widespread effects of salt on ecosystems at all trophic levels from biofilms to fish species. Specific effects vary based on exposure concentrations, and may include reductions in fecundity, size, shape, growth and abundance (Hintz and Relyea, 2019)[3]

Vegetation[edit]

Salt affects vegetation in various ways. Salt in soil water generally makes it more difficult for roots to take up water. This phenomenon mimics drought conditions for the plant and underlies the recommendation for salt tolerant plants in LID practices. If passing traffic sprays salty water onto plants it can reduce cold hardiness in buds and new twigs. These then become more susceptible to freezing, mortality or deformation. In high enough concentrations, sodium and chloride can also be directly toxic to plants. In some species the ions are absorbed by the plant and build up in the leaves causing them to die.

Soils[edit]

Dissolved sodium ions may replace calcium and magnesium ions in soil minerals, with negative effects on soil structure, hydraulic properties and fertility. Salt can also cause trace metals to be leached from the soil and into groundwater (e.g. Norrström and Bergstedt, 2001[5]; Norrström, 2005[6]). Excess salt (chloride) in soils can also result in decreased hydraulic conductivity, which can lead to increased occurrences of surface runoff, erosion and ultimately anaerobic soils, where plants would have a hard time establishing themselves (Shannon et al. 2020[7]).

Human Health[edit]

Salt has an unpleasant taste in drinking water at chloride concentrations above 250 mg/L. It also poses risks to people with hypertension or to those who have experienced congestive heart failure. Sodium from winter salts can also be dangerous for people on sodium restricted diets. These aesthetic and human health impacts of salt, combined with its high mobility in soils, has led to recommendations to limit implementation of infiltration-based LID in source water protection areas. This is of particular relevance for communities that utilize groundwater as their primary source of drinking water.

Terrestrial Wildlife[edit]

Ingestion of road salts has been associated with mammalian and avian behavioral and toxicological effects. Indirect effects of plant cover reductions or shifts in plant communicates can also negatively impact wildlife habitat (Fay and Shi, 2012)[8]. Deer, moose and other mammals attracted by salt on highways can increase the risk of vehicle collisions. Furthermore, various bird species can be be sensitive to even small amount of rock salt ingestion. These birds may be attracted to roads dude to salt deficient diets and foraging for "grit" (which aids in the birds digestion by grinding up hard to breakdown items). A 2005 study conducted by Bollinger, et al.[9] discovered that salt grain amounts similar in size foraged as grit by birds could contain lethal amounts of sodium for these birds. Ingestion of even a small number of road salt granules by some bird species (songbirds, etc.) could be a lethal dose as a result of sodium (Na) toxicity.

Built Infrastructure[edit]

Chloride based deicers are highly corrosive and can cause significant damage to vehicles, steel bridges, railings and other metal infrastructure. They can also cause damage to concrete structures by accelerating corrosion of re-bar within the concrete, which poses a problem for bridges, parking lots above underground garages or other contexts where the concrete contains metals. The salts may also react with the cement paste causing deterioration of the cement matrix in poured and pre-cast concrete pavers. Magnesium chloride (MgCl2) is particularly reactive in this regard, resulting in a decrease in concrete compressive strength (e.g. Shi 2009[10], Shi et al, 2009)[11].

Guidelines[edit]

Code of Practice[edit]

A comprehensive scientific assessment by Environment Canada and Health Canada determined that in sufficient concentrations, road salts containing inorganic chloride salts pose a risk to plants, animals and the aquatic environment (Environment Canada and Health Canada, 2001)[13] and are toxic substances as defined by the Canadian Environmental Protection Act, 1999 (CEPA 1999).[14]).

Following the designation of chloride as a toxic substance, the Government of Canada established a Code of Practice for the Environmental Management of Road Salts under CEPA to help municipalities and other road authorities to better manage road salt use and reduce the adverse impacts of chloride, which maintaining road safety (Environment Canada, 2004)[15].

The Code recommended, on a voluntary basis, that road authorities and municipalities applying more than 500 tonnes of road salt per develop salt management plans and implement best management practices for salt application, salt storage and snow disposal as described in the Transportation Association of Canada’s (TAC) Synthesis of Salt Management Best Practices (TAC, 2015)[16]. The Code does not address the use of road salt on parking lots and private property or its use as a dust suppressant but a Best Practice document specifically for these areas was developed by TAC in 2013.

Canadian Water Quality Guidelines for the Protection of Aquatic Life[edit]

The Canadian Water Quality Guidelines for the Protection of Aquatic Life[17] document from the Canadian Council of Ministers of the Environment (CCME) is another valuable paper that discusses the direct toxic effects of chloride, based on studies using NaCl and CaCl2 salts. The guideline can be used as a screening and management tool to ensure that chloride does not lead to the degradation of the aquatic environment. Further guidance on the application of these guidelines is provided in the scientific criteria document (CCME 2011), which can be found here - Scientific Criteria Document - Cl Ion. Both documents developed chloride toxicity thresholds for protection of aquatic in 2011 based on a comprehensive scientific review.

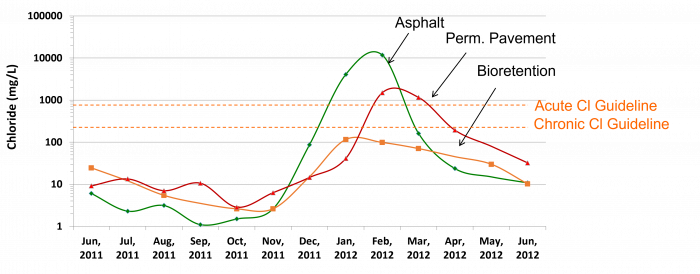

- Chronic toxicity (long duration exposure): 120 mg/L

- Acute toxicity (short duration exposure): 640 mg/L

Canadian Drinking Water Guidelines[edit]

The Canadian Drinking Water Guidelines (CDMG) are published by Health Canada. Health Canada updates its summary table for known irritants/pollutants and publishes it online every spring on their website here: (Health Canada's, Drinking Water Quality Table) (Health Canada, 2020)[18]. Below are the drinking water guidelines for both Chloride and Sodium found within rock salt:

- An aesthetic objective for Chloride of 250 mg/L was developed for drinking water supplies based on taste and potential for corrosion in the distribution system.

- Sodium also has an aesthetic objective of 200 mg/L based on taste, as well as a guideline of 20 mg/L for people on sodium restricted diets

Observed Stream Concentrations[edit]

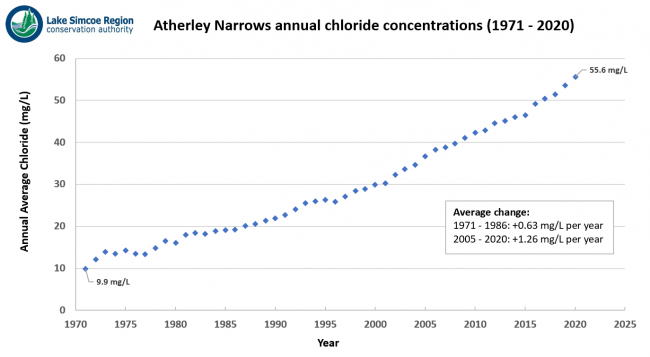

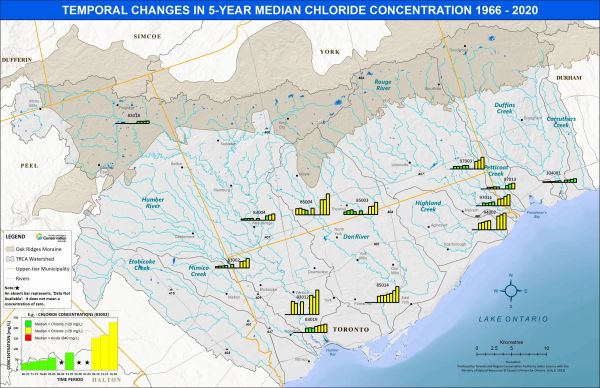

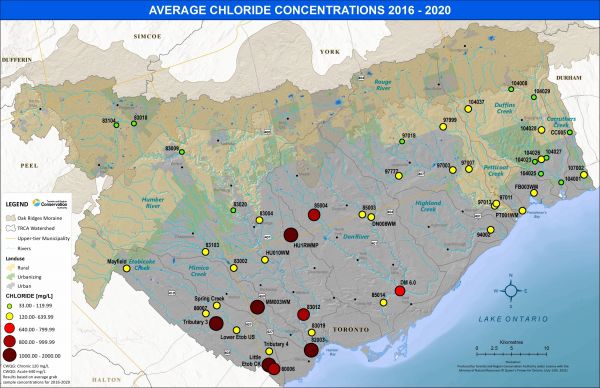

Monitoring data show that our freshwater resources are become increasingly salinized, particularly in urban areas. As the graphic shows, several urban streams in the GTA have average chloride concentrations exceeding the chronic toxicity threshold, and at some monitoring stations, even the acute toxicity threshold is exceeded. This is not just a winter problem; it can take months for water to move through the soils and into the rivers, resulting in high concentrations even in the spring and summer during sensitive life stages for many aquatic species.

In 2022, on-line sensors were installed to measure chloride concentrations at the mouth of several GTA watersheds. The monitoring results included: (Wallace, et al. 2022.)[19]

- Highland Creek: (Peak concentration of 8,400 mg/L) - 70 times the CWQG limit for chronic effects & 13 times the CWQG limit for acute effects of aquatic organisms.

- Duffins Creek: (Peak concentration of ~3,000 mg/L) - 25 times the CWQG limit for chronic effects & ~5 times the CWQG limit for acute effects of aquatic organisms.

These high concentrations pose a considerable threat to fish, aquatic organisms, and ecosystem health overall - especially considering the frequency and duration of these values in major watercourses in urbanized areas of the province. The findings highlight the need for increased water monitoring efforts and requirements for new sensor technology to capture an accurate representation of the current state of our rivers and streams.

In previous years, chloride concentrations greater than sea level concentrations (19,000 mg/L) have been observed in tributaries of the Credit River.

Salt & LID[edit]

Since salt has deleterious effects on many plant species, there is often concern that plants in LID receiving salt laden road runoff will not fare well over time. Several design features are meant to address these risks, including:

- Selection of plants tolerant to elevated soil concentrations of salt (Salt tolerance in plants)

- Inclusion of sumps or forebays without plants that reduce loads through infiltration

- High permeability soils that allow more rapid flushing of salt from soils during rain events (Specialized High permeable soils)

- Perforated distribution pipes that are offset from root balls to reduce exposure during early tree establishment (Stormwater Tree Trenches)

In drinking water protection areas, bypasses may be used to limit exposure to road salts during winter months where aquifers are vulnerable and ensures that any heavily-laden stormwater will "bypass" the practice and flow to the downstream street inlet to the Municipality's storm sewer system.

LID typically delays the release of salt to receiving waters through temporary storage of elevated chloride levels in soils and then slowly releases it over time. This can help to reduce peak concentrations in discharges and push discharges into the spring when streams have greater dilution capacity. Runoff infiltration in LID practices also helps reduce salt loading to streams that can harm riparian, aquatic and semi-aquatic fauna and flora species.

Permeable pavements can improve drainage and prevent melt water from ponding and refreezing. Some permeable pavements also have higher friction coefficients that may reduce the amount of salt needed to create slip-free surfaces.

Salt Reduction Best Practices[edit]

Since salt is not removed by traditional best practices, reducing application rates to only what is needed to achieve pavement safety requirements is the best means of managing impacts of salt on the environment and infrastructure. Pavement friction testing has shown that salting beyond the required amount does not translate into improved safety: LSRCA's Technical Bulletin: Alternatives to Salt.[20]

A review of salt management best practices for parking lots, private drives and walkways is provided by STEP (2022)[21]. The Transportation Association of Canada's (TAC), Synthesis of Salt Management Best Practices[22] and Clear Roads research[23]and provides best practice resources more relevant to municipalities and road authorities. The following sections outline what property owners/managers and winter maintenance professionals can do to avoid excess salting.

Property Owners and Managers[edit]

Property owners and managers play a critical role in creating safe winter conditions and managing the environmental impacts of winter salt on their sites. Some key activities property managers and owners can do to limit salt use without compromising safety include:

Site Assessment and Planning[edit]

This activity is often done with contractors to identify appropriate snow storage areas, vehicle impact hazards, problem areas such as grading that directs melt water or precipitation to walkways, roof downspouts directed to paved areas, or infrastructure that could be damaged by snowplows. A winter maintenance policy stipulating the expected weather-based level of service, areas requiring winter maintenance and other guiding elements should also be developed as part of a winter risk management strategy. Certification of the property(ies) through the Smart about Salt Council can help property managers through the process of developing a plan and policy, while also demonstrating how the organization has endeavored to provide a reasonable level of care in the event of lawsuits.

On-Site Equipment[edit]

Salt storage and spreading equipment, such as salt boxes, liquid storage containers, and walkway spreading devices can be used by building management staff for periodic or spot treatments, which may reduce requests for contractors to return to the site to apply more salt. On-site mobile or in-pavement temperature and salt residue sensors, along with weather forecasting tools are also useful to inform salting decisions and provide building managers with tools to verify that the salting approaches applied to the site and discussed with contractors as part of the winter maintenance plan are appropriately tailored to site conditions.

Record Keeping[edit]

Responsibilities for tracking winter conditions and maintenance activities should be shared by contractors and property management staff. On-site cameras can be particularly useful in this regard, particularly if the feeds' from these cameras are also shared remotely with contractors. Tracking equipment can help resolve potential conflicts between property management and contractors, contribute to learning through trial and error, ensure the winter maintenance plan is being followed and provide due diligence evidence in the event of slip and fall lawsuits. Liability for "slip and fall" claims associated with winter maintenance are outlined under "Bill 118 - Ontario’s Occupiers’ Liability Act". The Act was recently amended in January of 2021 and effectively disallows "any action for personal injury damages caused by snow or ice conditions against an occupier or independent contractor employed to remove snow or ice from the premises when the injury occurred unless a written notice of the claim is personally served on or sent by registered mail to such the occupier or independent contractor within 60 days" - Robert Kennaley, 2021[25] (some exceptions apply if the injury results in death, along with other more extreme cases). These recent changes will result in a reduction in associated claims and insurance payouts, thus leading to likely lower insurance premiums for contractors that historically have been high since the 1990s (Kennaley, 2021)[25].

Responsible Procurement[edit]

It is important that winter maintenance contracts be structured not only to ensure that salting and plowing activities promote safe conditions throughout the winter, but also to ensure that contracts are oriented towards minimizing the harmful effects of salt on freshwater ecosystems, drinking water, soils, vegetation and wildlife. Property owners, businesses and contractors have control over how much salt is applied through their snow and ice management contracts, and the diligence with which they manage and oversee these contracts. Some clauses and conditions that can be included in contracts to promote responsible use of winter salts include:

- Requirements that snow and ice professionals be Smart about Salt certified;

- Specification that various best management practices be used;

- Clearly articulated expectations for level of service and salt application rates based on weather and site conditions;

- Requirements for record keeping on salt use, time of applications and location;

- Avoiding excessive use of hold harmless clauses that place undue legal liability burdens on contractors;

- Structuring contract pricing structure based on number of events or season to avoid incentivizing salt use.

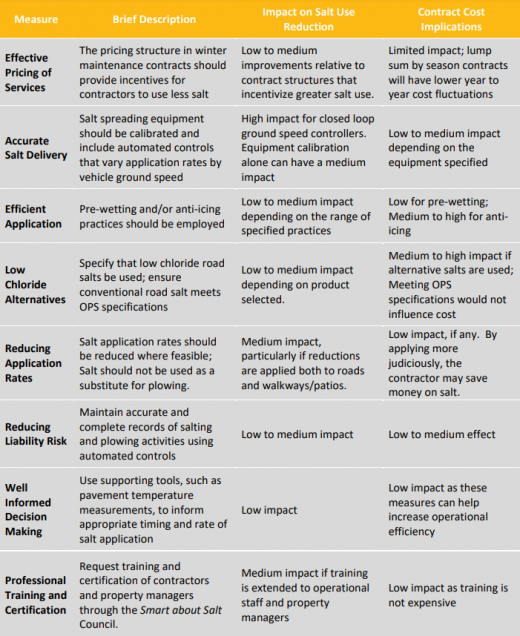

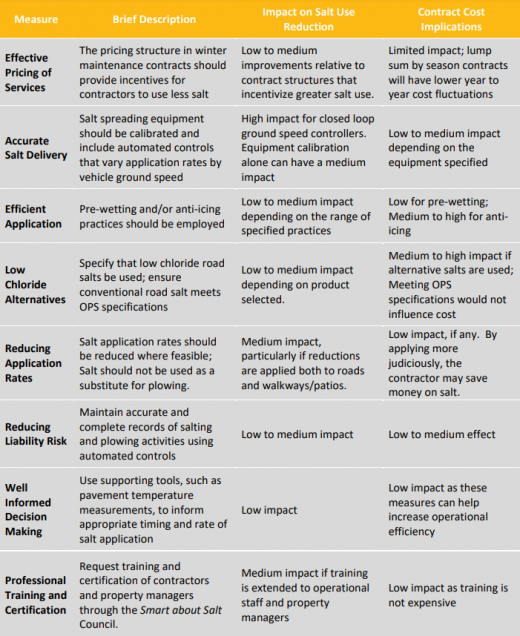

Examples of the types of best management practices that may be considered when preparing contracts are also provided in the STEP's Procurement Guidance for Parking Lot Snow and Ice Management report (STEP, 2019)[24], along with estimates of the impact on salt use, and the potential influence these may have on contract costs.

Minimizing the Area requiring Winter Maintenance[edit]

Properties with large parking lots often present owners with opportunities to close portions of parking lots and entranceways to public and employee use during the winter, either on a seasonal basis or during certain low use periods. Appropriate signage may need to be installed to inform staff and visitors that these areas are not to be used. This measure can generate significant savings through reduced material use and labour, while also reducing the potential area where snow and ice may contribute to safety and liability concerns.

Improved Parking Lot and Walkway Design[edit]

In new developments or when pavements are repaired or upgraded there are often opportunities to improve drainage, grading or pavement features to reduce the amount of salt needed during winter maintenance. Design changes may include, but is not limited to grading to keep meltwater away from trafficked areas, directing downspouts away from paved areas, installing windbreaks, avoiding flat grades that will eventually form depressions where water can puddle, creating designated snow storage areas that drain away from pavements and installing covers, heated pavements or pavement overlays that can be maintained with less salt (LSRCA, 2018)[26]. See below for more details.

Good Ontario resources on winter maintenance strategies for private businesses and property owners/managers include:

Winter Maintenance Professionals[edit]

Selected best management practices for winter maintenance professionals include the following (Van Seters, 2022)[21]

Best Practice |

General Description |

Key Benefits |

|---|---|---|

| Contract pricing by season or event (contractor and property owner/manager) |

Snow and Ice professionals are paid a fixed priced per season or event. | Reduces salt use by not incentivizing the use of salt through the pricing structure in contracts. |

| Site condition assessments and plans (contractor and property owner/manager) |

Site assessments and plans identify and document site conditions, problem areas to be rectified, service areas and levels, snow storage areas, and expectations. | Improves operational efficiencies; supports due diligence defense; prevents potential client contractor conflicts; reduces the need for repeat salt applications on problem areas. |

| Flexible level of service requirements (depending on conditions) |

Since salt needs time to work, there is invariably a delay between when it is applied and when the specified bare pavement service level is met. This delay can be lengthened under circumstances when bare pavement is needed only during daytime business hours and the snowstorm ends several hours before the day starts. If applicable, flexible LOS requirements should be described in the site winter maintenance plan. | Significantly reduces salt use because research has shown that the quantity of de-icer applied is strongly influenced by the bare pavement level of service target. |

| Materials | Rock salt pretreated with liquid MgCl2 or CaCl2 lowers the effective temperature range of salt and reduces losses to wind and scatter. Low chloride alternatives can also significantly reduce the harmful effects of chloride-based salts. | Reduces salt release to the environment and lowers corrosion effects on infrastructure. May also lead to improved level of service. For more information see STEP, 2020. Abrasives such as sand dot not melt snow and ice but may be appropriate in some circumstances and LSRCA, 2018. |

| Salt Specifications | In Ontario, NaCl rock salts and brines used for snow and ice control should meet Ontario Provincial Standard Specifications (OPSS 2502, OPSS Mun 2502) for moisture content, texture, and chemistry to ensure optimal performance. | Rock salt texture and moisture helps regulate dilution rates, bounce, blow off and other factors that can negatively influence overall effectiveness. |

| Direct Liquid Application | Involves applying brine before, during or after snow events to prevent ice formation on pavement and walkways. Anti-icing is the application of a brine or treated rock salt before snow events. | Less salt is required to prevent ice -pavement bonding than to break the bond after it has formed. Salt savings of 39 to 46% are common. Can improve overall level of service and support due diligence defense. |

| Pre-Wetting | Applying a concentrated liquid anti-icing rock salt at the spinner or chute increases moisture content, which in turn promotes quicker activation and better adherence of salt to pavements. | Reduces salt use by approximately 20% (STEP, 2022). Similar benefits may be accomplished by pre-treating salt stockpiles with liquid or using proprietary pre-treated salt products. |

| Ground Speed Controllers | Salt spreaders are equipped with controllers that automatically dispense salt based on truck speed. | Research shows salt reductions up to 49% compared to manually controlled spreaders. Particularly relevant for parking lots where salt trucks are frequently required to vary speeds and stop/start. |

| Vehicle Tracking Equipment | Use of Global Positioning System (GPS) and Advanced Vehicle Location (AVL) technologies that track the location of vehicles. Often implemented with controllers to provide operational data along with location data. | When combine with operational data collection systems, GPS and AVL can improve operational efficiencies and increase operator accountability. The data are extremely helpful in supporting due diligence defense. |

| Decision Support Tools (basic) |

May include use of RWIS, pavement temperature and residual salt monitoring, on-site cameras and decision support software/systems. Example RWIS: Wood Weather Information System | Helps optimize event-based winter maintenance strategy (timing, material selection, etc.); supports due diligence defense. |

| Equipment Calibration (once a year and after repair) |

Salt spreading equipment (solid and liquid) is calibrated to ensure it is functioning and applying salt at the calibrated rates. Both vehicle spreaders and walk behind drop spreaders should be calibrated. | Ensures accurate and efficient delivery of material to pavements and walkways; avoids use of malfunctioning equipment; supports due diligence defense. |

| Plowing before Salting | Plow at snow depth accumulations > 2 to 3 cm. Spreading salt on top of snow dilutes its effectiveness thereby requiring more salt to achieve desired level of service. | Avoids dilution of salt and improves effectiveness, which significantly reduces salt use; more frequent plowing can support due diligence defense. |

| Segmented or Live Edge Snowplow Blades | Segmented or Live Edge snowplow blades remove more snow than traditional blades by conforming better to the surface contours of the pavement. | Reduces salt use because the salt applied is not diluted by residual snow on the surface; may provide higher level of service while also offering some support to due diligence defense. |

| Setting Application Rates based on conditions |

Establishing target liquid and solid de-icing material rates for a range of conditions based on temperature, residual salt on pavements, snowfall depth and duration and other key parameters. Rates suited to different conditions are ranges to allow for some decision-making flexibility | Adjusting salt application rates according to conditions helps ensure that only the amount needed to promote safe conditions is used. Documentation supporting the selection of rates can help support due diligence defense. |

| Record Keeping | Records and logs should be kept of equipment calibration and maintenance, weather, salt use by load, maintenance schedules, site conditions, staff training, site contracts, trouble spots and other parameters relevant to winter maintenance operations. See also site condition assessments and planning section above. | Documentation supports due diligence defense and provides critical information for assessing overall performance and identifying where improvements may be needed. Often leads to significant salt reduction. |

| Material Storage and Handling | De-icing materials should be covered and isolated from other site drainage. Spilled salt in handling areas should be collected and returned to the storage facility. Storage and handling areas should be impervious to prevent contamination of soils and groundwater. Vehicle wash water should be properly managed. | Avoids unnecessary release of salt into the environment; reduces costs associated with material loss. |

| Snow Storage | Snow should be stored in low sections of site to prevent melt water and re-freeze on pavements. Snow transported off site should go to proper snow disposal facility. | Avoids release of salt into the environment; Reduces salt by eliminating re-freeze conditions that can cause repeat applications; supports due diligence defense. |

| Training | Training of all winter maintenance staff through Smart about Salt Council and/or other equivalent certification programs. | Training is widely recognized as a critical component to responsible use of salt; supports due diligence defense. |

For more information on the practices and research supporting the suggested benefits, see [STEP, 2022][21] and [TAC, 2013], and associated reference materials.

Salt Alternatives[edit]

Due to rock salt's numerous impacts on both infrastructure and the environment numerous studies have been conducted to determine if there are adequate alternatives to the practice of salt application to parking lots and roads. These include sand, organic de-icing materials (agricultural by-products), and salt water brine to name a few.

Below find a summary table of common de-icers and alternatives in comparison to rock salt regarding lowest working temperature, cost estimations and average application rates.

| Deicer | Cost Estimate (low $ - high $$$$) | Typical Application Rates (average range) | Lowest Practical Working Temperature (°C) |

|---|---|---|---|

| NaCl (Rock Salt) | $ | ~130 kg/2 lane km, depending on conditions (range 70-220 kg/2-lane km in Lake Simcoe watershed) | -9 |

| MgCl2 (Liquid Brine) | $$ | Liquid anti-icing: 35-59 L/2-lane km | -15 |

| CaCl2 (Liquid Brine) | $$$ | Liquid anti-icing: 35-59 L/2-lane km | -29 |

| Treated Rock Salt | $$ | 72-130 kg/2-lane km | -17 |

| Calcium Magnesium Acetate | $$$$ | 219-292 kg/2-lane km (for first application, lower for subsequent due to residual effect) | -7 |

| Agricultural By-Products | Varied Cost ($$ - $$$$) | Varies; often used to pre-wet rock salt – less salt is required, lowest effective temperature is reduced | -17 to -23 |

Agricultural By-Products & Brine[edit]

Many municipalities have found treated rock salt to be worth the extra investment, due to its increased effectiveness at lower temperatures and lower application rate when compared to standard rock salt application practices. The process of pre-wetting rock salt with brine or an agricultural by-product (beet juice for example) as it is applied can help the mixture better adhere to road and pavement surfaces better and reduce excess waste and can enhance the effectiveness of rock salt application below -12°C. To note, the effectiveness of agricultural by-products is still under some evaluation, as some major cities, including Toronto, use it under certain conditions, several Lake Simcoe watershed municipalities have tested it and found it not to be as effective as rock salt. Furthermore, agricultural by-products have to be applied before a snowfall event to melt the fallen snow in a relatively short period of time, which generally is not possible or practical (if applied after a snowfall event it takes a long time to begin the melting process). Read more about these alternative applications in STEP's Technical Brief: Alternatives to Salt[27].

Detailed analysis of the performance of varying de-icer agents and liquid brine can be found in STEP's earlier technical brief entitled, Evaluation of Organic Anti-icing Materials for Winter Maintenance.[29]. The document describes the practice of "anti-icing", (applying liquid brine solutions to paved surfaces before a winter storm) to help prevent ice and snow from bonding to the roadway surface, which in turn helps to reduce the amount of rock salt required to remove salt and ice.

Sand[edit]

Property managers often turn to sand as an alternative to salt, as it is thought to be a less harmful option. Sand has been used, either on its own or mixed with salt, as a core part of many municipalities’ or individual property managers’ winter maintenance practices. It is used similarly to rock salt as it is applied to increase friction between snowy or icy pavement and the vehicles/pedestrians passing over it. Of those municipalities that use sand, rural ones with a higher proportion of gravel roads use almost exclusively sand (with a small percentage of salt mixed in to prevent freezing and caking), while other municipalities often use a sand-salt mix at various ratios

The general issues with sand are that:

- Most sand applied blows off the road within relatively few (e.g. 8-12) vehicle passes at speeds over 40 km/hr (general speed limits of most municipal subdivision streets); rendering any improvement in friction temporary, at best.

- Pre-wetting can help sand adhere to the road, but there is little to no increase in its friction coefficient even with this pretreatment approach.

- When sand mixes with melting snow it doesn't embed itself in the snow but rather becomes more of a slushy mixture that accumulates on the side of roads, or worse within SWM features (catch basins, stormwater ponds, etc.).

- The associated cost municipalities incur as a result of sand accumulation along roadways, curbsides and in SWM features are due to the additional effort required (more frequent catchbasin cleanouts, etc.) and the cost of sweeping up this material at the end of each winter season to reduce ongoing environmental impacts.

- Due to contamination of sand, disposal is becoming a more complicated, and therefore costly process causing a number of municipalities to re-evaluate their winter maintenance programs, when it comes to using sand.

Read LSRCA's Technical Bulletin: Sand versus Salt[30] document to learn more about exploring the efficacy of the use of sand for winter maintenance, its associated environmental issues, and where its use is most appropriate.

Design Strategies for Salt Reduction[edit]

In their 2001 assessment under the Canadian Environmental Protection Act, it was found that high releases of road salts from winter maintenance activities were having an adverse effect on freshwater ecosystems, soil, vegetation, and wildlife (Environment Canada, 2001)[31]. Based on this conclusion, Environment Canada developed its “Code of Practice the Environmental Management of Road Salts,” which focuses mainly on municipal and provincial road maintenance. This code, which requires the development of Salt Management Plans for those organizations using more than 500 tonnes of road salt annually, was released by Environment Canada in 2004 (Environment Canada, 2004)[32]. While the uptake of this code of practice has been successful for municipalities, there is not a similar recognized guideline for parking lot contractors. That said, there are studies and training programs that address this issue, which aims to educate private contractors about best practices, and how these can improve their level of service, protect the environment, and reduce associated costs. However, uptake of these programs has been low. To address this gap, LSRCA and its partner agencies identified a need for a guideline document that could be used by designers, regulatory agencies, owners, contractors, and others to consider design elements in the design and layout of parking lots and related infrastructure that can help to reduce the requirement for salt application. This effort culminated in the development of LSRCA's Parking Lot Design Guidelines[33]

- LSRCA has created a landing page with their partners, which include three key documents:

- Fact Sheet - Parking Lot Guidelines: Highlights the impacts of elevated chloride levels in freshwater systems in the Lake Simcoe watershed and detailed, bullet-point descriptions of how to design parking lots to limit over application of rock salt.

- Parking Lot design Guidelines - Full Report: Written in partnership with GHD the Parking Lot Design Guidelines to Promote Salt reduction is the primary document LSRCA uses to provide background on the issue of over salting roads and parking lots, primary design features for owners and contractors to consider, case study and site examples where the guidelines have been followed and Drawings of these sites that can be found on the main Parking Lot Guideline landing page.

- Municipal Policy Template: This template document aids municipalities in the drafting of their own parking lot design and salt reduction policy document based on the findings and design guidance from LSRCA's Parking Lot design Guidelines - Full Report, 2017.

The LSRCA's commissioned study with GHD describes preferred salt management design strategies for parking lots, which can be read here: LSRCA salt guide. The report identified four key design strategies. They can be seen summarized below:

Effective Grading[edit]

- Proper grading can minimize the freezing of wet pavement surfaces and prevent melt water from ponding and re-freezing, reducing the need for re-application of salt.

- Areas for vehicular and pedestrian traffic should be graded between 2 - 4 % to reduce the chances of depressions forming over time (maximum permitted 5% for AODA). Small depressions can result in ponded water icing over in the winter.

- Subbase should be well compacted for the same reason.

- In winter months efficient salt application should be made along the top of slopes; melting snow will carry the salt solution down-gradient.

- Effective grading can also direct melt water towards strategically placed stormwater collection infrastructure (i.e. catch basins, vegetated swales, bioretention features, landscaped areas), preventing salt application in heavy traffic areas that are also pathways for runoff.

- The key to effective stormwater collection during winter is to ensure that melt water from high traffic areas or snow piles does not have to travel great distances to a collection point.[34].

Snow Pile Location[edit]

- Snow piles should be strategically located to minimize the risk of melt water draining across high traffic areas and refreezing.

- Storage locations for snow piles should be around the outer edges of parking lots and downgradient from high traffic areas, in sunny areas where possible to accelerate melting.

- Consider grading the storage location to distribute the melt-water as sheet flow over a grass filter strip into an adjacent BMP, such as a bioretention cell or infiltration trench. In some cases, with careful vegetation selection and adequate drainage, the BMP itself can serve as a snow storage location. Designing specific drainage collection features for snow piles can ensure that melt water is quickly collected in the vicinity of the pile to reduce the opportunity for refreezing.

- Snow storage areas should be clearly marked for seasonal maintenance staff.[35].

Sidewalk Design and Pedestrian Flow[edit]

- The design process should consider that pedestrians typically follow the path of shortest distance and do not necessarily use designed walkways. Walkways from adjacent residential areas and transit stops should be prioritized, and unnecessary walkways should be avoided.

- Sidewalks that receive infrequent use could be closed for the winter season.

- Maintained sidewalks should be ≥ 1.5 m wide to accommodate plowing and minimize the salting required.

- Using textured pavers can improve grip for pedestrians, again reducing the salt required.

- In busy areas around building entrances, covered walkways and heated mats also reduce salt requirements.[36].

Landscaping Features[edit]

Trees[edit]

- Landscaping features (i.e. vegetated swales or landscaped islands) can lead to a reduced requirement of salt application by reducing the amount of paved surface.

- Specifying deciduous trees along walkways and near snow piles will maximize winter sunlight penetration. This will naturally enhance the melting of frozen surfaces, limiting the need for winter maintenance.

- Coniferous trees can be used to create treed wind breaks along the site perimeter to avoid snow drifts.[37].

Other vegetation[edit]

Vegetation varies in its reaction to soils with high salinity:

- Salt in soil water generally makes it more difficult for roots to take up water. This phenomenon mimics drought conditions for the plant.

- If passing traffic sprays salty water onto plants it can reduce cold hardiness in buds and new twigs. These then become more susceptible to freezing, mortality or deformation.

- In high enough concentrations, sodium and chloride can also be directly toxic to plants. In some species the ions are absorbed by the plant and build up in the leaves causing them to die.

Generally, the vegetation growing closest to the source will be most strongly affected by salt. Plants actively growing in late winter (when salt levels are highest) are also more significantly affected. So, warm season grasses offer an advantage over cool season grasses, because they emerge later in the spring when excess salt has been flushed away. Resilient turf grasses are particularly useful in the design of vegetated filter strips, dry ponds and enhanced grass swales. The Ministry of Transportation have standardized a number of grass mixes[38]. The 'Salt Tolerant Mix' is of particular value for low impact development applications alongside asphalt roadways and paved walkways.

| Common name | Scientific name | Proportion |

|---|---|---|

| Tall Fescue | Festuca arundinacea | 25 % |

| Fults Alkali Grass | Puccinellia distans | 20 % |

| Creeping Red Fescue | Festuca rubra | 25 % |

| Perennial ryegrass | Lolium perrenne | 20 % |

| Hard Fescue | Festuca trachyphylla | 10 % |

Other Design Features[edit]

Other options that can be considered to reduce the amount of salt that needs to be applied in a parking lot include:

- The use of permeable pavers: these improve drainage and prevent melt water from ponding and refreezing.

- Seasonally closing parking areas: many parking lots have areas that are infrequently used outside of the holiday shopping period. These areas can be closed and not maintained through much of the winter season, reducing both the effort and amount of salt required.

- Shaded Canopies: With roof canopies over major pedestrian walkways and entrances from parking lots to building enclosures, little to no snow or ice will fall in these high-traffic areas, resulting in reduced salt application. Consideration should be taken for the runoff generated from the canopy stormwater or snowmelt when weather begins to warm to limit the potential for of ponding/refreezing on the walkway.

- Conductive Pavement on Walkways/Entrances: Conductive pavements consist of electrically and thermally conductive materials mixed with the dielectric aggregates typically found in standard asphalt and concrete pavements. Once connected to a power or heat source, these pavements conduct electricity and emit heat to pavement surfaces, melting ice and snow with constant and uniform heat.

- Brine holding tanks: Collection of first flush (high chloride concentration) melt water runoff from a salt induced snowmelt (as opposed to rain and temperature induced snowmelt) has the potential to be beneficial if captured and reused as an anti-icing or pre wetting solution. In order to collect the first flush runoff, an electronically actuated valve controlled by an electrical conductivity sensor would be installed at the desired conveyance point to divert and collect the high chloride concentration runoff into a brine holding tank. The brine holding tank would be placed below ground and a pump could be connected to pump the brine solution into an anti-icing tank or directly used to pre-wet rock salt. [40]

Procurement Guidance[edit]

Contracts for snow and ice management on private parking lots are typically oriented towards ensuring that plowing and salting promotes safe conditions throughout the winter, and that interruptions to regular business operations are kept to a minimum. The first thought of many people may be that applying more salt is safer for their patrons and workers but, applying more than is necessary not only harms the environment, as previously mentioned but also shortens the life of parking lot surfaces and can accelerate the process of corrosion of nearby buildings or transportation infrastructure on site, not to mention the extra cost of unnecessary road salt application. Property owners, businesses and contractors have control over how much salt is applied through their snow and ice management contracts, and the diligence with which they manage and oversee these contracts. The Procurement Guidance for Parking Lot Snow and Ice Management by STEP [42] describes various clauses and conditions that can be considered by these groups to be included in contracts to promote the responsible use of road salts. A summary of the measures are provided in with estimates of the impact on salt use, and the potential influence these may have on contract costs.

Procurement Best Practices[edit]

Businesses can help reduce over-salting by ensuring that rock salt during the winter months is applied responsibly on parking lots and walkways. An easy way to do this is by ensuring that your snow and ice maintenance contract includes provisions requesting that industry best practices be employed and that associated operators are adequately trained.

Some BMP for procurement for rock salt application services include:

- Effective Pricing of Services: Contract pricing by a lump sum by season or a fixed sum per event (with extra costs associated with standby time) are common, but a combination of both payment options in the contract may create a financial incentive for both the parking-lot owner and salt operator to require less salt.

- Accurate Salt Delivery: Updated and well-maintained salt application devices (i.e. salt spreaders) that can be calibrated to function and apply salt automatically based on the speed of the vehicle can greatly reduce the amount of rock salt applied and can better digitally track the amount used as well.

- Reducing Liability Risk: Ensuring records and evidence of when, where and how plowing and salting practices were performed on site better protect the owner of the parking lot and contractor who applied the practices from potential slip and fall lawsuits.

- Efficient Application: Consideration of pre-wetting or anti-icing with liquid salt brine before events will help accelerate the melting process during and after an event and help salt better adhere to the road/parking lot surface.

- Consideration of Chloride Alternatives: Alternatives previously mentioned on this page such as acetates, formates, agricultural by-products (beet juice) can be used instead of rock salt (where feasible) or can be used as an anti-icing / pre-wetting agent.

- Well Informed Decision Making Processes: Use of local weather forecasts, up-to-the-minute road information systems, internet based radar tracking and infrared thermometers to determine pavement temperatures can better decision making options that save time on salt, contractor crew capacity and money.

- Trained Professionals: Requesting evidence of experience and requiring training and certification through the Ontario Smart about Salt Program will help to ensure that the contractor selected and property management staff have the skills necessary to implement best practices for road salt application.

To learn more about STEP's Salt Application Best Practices document for Winter Maintenance Contracts[43] click on the hyperlink.

Parking Lot Friction Testing[edit]

LSRCA's Technical Bulletin: Alternatives to Salt[44] is a valuable technical brief which covers BMPs that have been developed specifically for winter maintenance in parking lots. Along with recommendations around the proper use and calibration of equipment, many of these practices relate to plowing the lot and walkways before applying salt, and applying the recommended amount of salt for the conditions. Several studies have been conducted, by industry and academia, to determine what the “right” amount of salt is, and, while “proper” application can vary depending on temperature and conditions 58 g/m2 (or 13 lb/1000 ft2) has been suggested as a reasonable rate to use for “moderate” winter events (Hossain, K. and Fu, L., 2015), while in recent studies of commercial parking lots by LSRCA, the typical real-world application rates tended to be closer to 90 g/m2 (or 18 lb/1000 ft2), and can often be much higher.

This report talks about main considerations contractors face in maintaining parking lots in winter:

- What application rate should be used?

- What is the level of service expected by the client, for which the bare pavement return time is a common measure?

- (This is the amount of time it takes after treatment to achieve a bare surface)

In order to better understand these questions; in 2017 the LSRCA obtained a friction tester, with a goal of quantifying the effectiveness of various practices and salt application rates. LSRCA’s friction testing showed that bare pavement is safest, as it has the highest friction value, and that the over-application of salt does not translate to safer conditions. To read more about the friction tester results continue on below, through the rest of this section.

As can be seen in the inset table, the unit for measuring friction is ‘µ’, and the closer to 1.00 the µ value, the safer the surface. A high µ, however, is not the only measure of safety – many smooth indoor floors will have low µ values, in the range of 0.3 to 0.4, and they are generally not considered unsafe. Through this study, friction of several different surfaces, which received varying treatments was measured by LSRCA staff.

| Measured Friction Value (µ) | Road Surface Condition |

|---|---|

| 0.8 - 1.00 | Dry, New Asphalt |

| 0.50 - 0.80 | Wet Asphalt |

| 0.30 - 0.50 | Wet Sand on Ice |

| 0.25 - 0.30 | Dry Sand on Ice |

| 0.25 - 0.25 | Dry Ice |

| 0.05 - 0.15 | Wet Ice |

High volumes of salt are often applied because contractors, property managers, and parking lot users feel that the more salt there is, the safer the surface is to walk or drive on. However, a surface that has been treated at an appropriate rate, (which is slightly wet with a small amount of salt residue) has a much higher friction value (μ); with the level of service achieved far more efficiently, than when compared to the same surface where rock salt has been heavily applied (over salted).

Through this work, as referenced above - LSRCA staff documented higher friction values on untreated surfaces than on surfaces with large volumes of product; the µ value of a surface may remain low if it has only been shoveled or plowed. While shoveling is an important part of the winter maintenance process, practitioners need to consider the site and predicted conditions on a day-to-day basis to determine how to attain the safest surface for vehicle and foot traffic. In many cases the sun or traffic may melt the residual snow on a shoveled or plowed surface without any further treatment being necessary (saving both time and money); while in other cases, some salt, applied at an appropriate rate, may be necessary.

Higher Costs, Little Benefit[edit]

Friction testing has demonstrated that bare pavement is safest, as it has the highest friction value, and that the over-application of salt does not always translate to safer conditions. Simply put, applying salt at the prescribed rate for the conditions and shoveling or plowing where appropriate will attain a higher friction rate than an overapplication of salt.

What is a reasonable amount of time to achieve the desired level of service?:

- Depending on the operating hours of the property being maintained, it may be possible to reduce the salt application rate without sacrificing the desired level of service.

- For example, many commercial properties keep hours between 9:00 am and 9:00 pm, which would mean that the lot does not need to be clear until shortly before 9:00 am. The table below demonstrates the time it would take to reach bare pavement at typical industry-recommended application rates, in a situation where the temperature is between -7 and -9 °C, with between 0.5 and 1.5 cm of snow on the ground. The rate may need to be increased or decreased slightly to achieve the desired level of service depending on varying factors related to traffic, sunlight, type of snow, and/or pavement type.

| Difference Among Scenarios | Time to bare pavement (hrs) | Application Rate (g/m2) | Volume of salt used for each application (kg)* | Total salt applied/season (tonnes)** | Material costs/season (assuming $100/tonne) |

|---|---|---|---|---|---|

| Scenario 1

|

2 | 87 | 13,050 | 913 | $91,300 |

| Scenario 2

|

3 | 58 | 8,700 | 609 | $60,900 |

| Difference

|

1 | 29 | 4,350 | 304 | $30,400 |

As the "Time to Reach Bare Pavement Scenario Comparison" above demonstrates, significant salt and cost savings could be seen in a typical big box store, commercial business or institutional building's parking lot by simply reducing the application rate of rock salt and extending the time to bare pavement by one hour. To note, this is only the material cost of the salt (which varies, but has been higher than $100/tonne in recent years (Tumilty, 2018)[45]. Over-application of salt has been noted to cause significant damage to parking lot infrastructure, including issues with concrete, corrosion of railings, damage to landscaping materials, and damage to interior buildings' flooring. Reducing the application rate would decrease the rate at which this damage occurs, as a result helping to minimize the amount needed to repair or replace at a given property each year. All of this without sacrificing the safety of parking lot users.

External links[edit]

- Smart about Salt[47]

- The website of the Smart About Salt Council (SASC) that offers training, recommendations, research and up to date news articles about the importance of proper management and use of rock salt on Ontario roadways, parking lots, private and residential properties. Training is offered in both English and French.

- Salt Application Verified Equipment (SAVE) Program: Managing Risk While Saving Money[48]

- The Salt Application Verified Equipment (SAVE) Program was developed to make the process of applying salt less subjective and encourage contractors providing snow and ice management services for parking lots and sidewalks to apply salt more efficiently. Through the program, salt spreading equipment is calibrated according to a standard test procedure, and contractors undertake in-field training to ensure familiarity with how to operate their equipment in a manner that achieves pre-determined target salt application rates. Equipment operators obtain annually renewable license and plate stickers to confirm that their equipment has been verified. The list of contractors with calibrated equipment is made available on-line for facility managers, property owners and property management companies to use in the procurement of snow and ice maintenance contracts for their properties. To learn more about the program click Here. And for further updates to the program's verification process visit SASC's page here.

- Good Practices for Winter Maintenance in Salt Vulnerable Areas. [49].

- This guidance is a living document to help address the impacts of road salt, within specific vulnerable areas, and will be reviewed every two years to remain current with technological and legislative changes. There are several types of ‘salt vulnerable areas’, with various environment and human health goals including drinking water quality, wetland health, and fisheries that are identified within the document. This guidance currently prioritizes certain areas where municipal drinking water sources are known to be impacted by road salt, know as, ‘Issue Contributing Areas’ (ICAs) delineated under the Clean Water Act (2006).

- Winter Parking Lot and Sidewalk Maintenance Manual[50]

- The purpose of this manual By the Minnesota Pollution Control Agency (MPCA) is to deliver practical advice to those managing parking lots and sidewalks and help make proactive, cost-effective, environmentally conscious choices in winter parking lot and sidewalk management in the State of Minnesota. This knowledge will provide the opportunity to become a leader in the industry by operating more efficiently and reducing environmental impacts. The manual is based on the Minnesota Snow and Ice Control Field Handbook for Snowplow Operators, produced by the Minnesota Local Technical Assistance Program Center, and on the training materials for the MPCA's Winter Maintenance of Parking Lots and Sidewalks training class.

- A review of the species, community, and ecosystem impacts of road salt salinisation in fresh waters. [51].

- This study of the impacts of road salt on local ecosystems by Hintz and Relyea (2019), found that road salts negatively affect species at all trophic levels, from biofilms to fish species but the concentration of road salt where adverse effects were observed varied and the effects themselves ranged from reductions in fecundity, size and shape to alterations to nutrient and energy flow at an ecosystem level and increased greenhouse gas emissions from contaminated wetlands and altered hydrology and oxygen, nitrogen and carbon level dynamics in lakes and streams. Concentrations at which road salt triggered an effect varied considerably. To read more about their findings, click the link above.

- Hamilton Salt Management Plan[52].

- The City of Hamilton's 2021 Salt Management Plan is intended to set out a policy and procedural framework for ensuring that the City continuously improves the management of road salt used in its winter maintenance operations. The plan is dynamic and allows the City to phase in new approaches and technologies in a way that is responsive to fiscal demands and the need to ensure that roadway safety is not compromised. To read more about the City's finalized plan that compares it's current practices to BMPs, opportunities for improvement, and achievement metrics which can be replicated for other Ontario municipalities, click the link above.

Proprietary Systems[edit]

In our effort to make this guide as functional as possible, we have decided to include proprietary systems and links to manufacturers websites. Inclusion of such links does not constitute endorsement by the Sustainable Technologies Evaluation Program.

- Camion™ - Salt brine holding tank systems for liquid salt brine storage.

References[edit]

- ↑ LSRCA. 2018. Parking Lot Design Guidelines: Municipal Policy Templates to Promote Salt Reduction in Parking Lots. https://www.lsrca.on.ca/Shared%20Documents/Parking-Lot-Design-Guidelines/Parking%20Lot%20Design%20Guidelines.pdf.

- ↑ Hossain, S.K., Fu, L. and Lake, R., 2015. Field evaluation of the performance of alternative deicers for winter maintenance of transportation facilities. Canadian Journal of Civil Engineering, 42(7), pp.437-448. https://cdnsciencepub.com/doi/abs/10.1139/cjce-2014-0423

- ↑ Hintz, W.D. and Relyea, R.A. 2019. A review of the species, community, and ecosystem impacts of road salt salinisation in fresh waters. Freshwater biology, 64(6), pp.1081-1097. https://www.researchgate.net/publication/331991752_A_review_of_the_species_community_and_ecosystem_impacts_of_road_salt_salinisation_in_fresh_waters

- ↑ Lambert, M.R., Stoler, A.B., Smylie, M.S., Relyea, R.A. and Skelly, D.K. 2017. Interactive effects of road salt and leaf litter on wood frog sex ratios and sexual size dimorphism. Canadian Journal of Fisheries and Aquatic Sciences, 74(2), pp.141-146. https://tspace.library.utoronto.ca/bitstream/1807/74970/1/cjfas-2016-0324.pdf

- ↑ Norrström, A.C., Bergstedt, E. 2001. The impact of sodium from de-icing salts on colloid dispersion and base cation pools in roadside soils. Water Air and Soil Pollution. Vol. 127. pp. 281-299. https://www.researchgate.net/publication/226123793_The_Impact_of_Road_De-Icing_Salts_NaCl_on_Colloid_Dispersion_and_Base_Cation_Pools_in_Roadside_Soils

- ↑ Norrström, A.C. 2005. Metal mobility by de-icing salt from an infiltration trench for highway runoff. Applied Geochemistry. Vol. 20, pp. 1907-1919. https://www.researchgate.net/publication/248337128_Norrstrom_A_C_Metal_mobility_by_de-icing_salt_from_an_infiltration_trench_for_highway_runoff_Applied_Geochemistry_20_1907-1919

- ↑ Shannon, T.P., Ahler, S.J., Mathers, A., Ziter, C.D. and Dugan, H.A., 2020. Road salt impact on soil electrical conductivity across an urban landscape. Journal of Urban Ecology, 6(1), p.juaa006. https://academic.oup.com/jue/article/6/1/juaa006/5741239?login=true

- ↑ Fay., L. and Shi., X. (2012). Environmental Impacts of Chemicals for Snow and Ice Control: State of the Knowledge. Water Air Soil Pollut 223:2751–2770. http://www.dot.state.mn.us/research/RFP/Lit/LS526a.pdf

- ↑ Bollinger, T.K., Mineau, P. and Wickstrom, M.L., 2005. Toxicity of sodium chloride to house sparrows (Passer domesticus). Journal of wildlife diseases, 41(2), pp.363-370. https://bioone.org/journals/Journal-of-Wildlife-Diseases/volume-41/issue-2/0090-3558-41.2.363/TOXICITY-OF-SODIUM-CHLORIDE-TO-HOUSE-SPARROWS-PASSER-DOMESTICUS/10.7589/0090-3558-41.2.363.pdf

- ↑ Shi, X., M. Akin, T. Pan, L. Fay, Y. Liu and Z. Yang (2009). Deicer Impacts on Pavement Materials: Introduction and Recent Developments. Open Civil Engineering Journal 3. https://opencivilengineeringjournal.com/VOLUME/3/PAGE/16/FULLTEXT/

- ↑ Shi, X., L. Fay, Z. X. Yang, T. A. Nguyen and Y. J. Liu (2009). Corrosion of Deicers to Metals in Transportation Infrastructure: Introduction and Recent Developments. Corrosion Reviews 27(1-2): 23-52. https://westerntransportationinstitute.org/wp-content/uploads/2016/08/4W1095_Intro_Developments.pdf

- ↑ 12.0 12.1 TRCA. 2021. Spatial Patterns (2016-2020) and Temporal Trends (1966-2020) in Stream Water Quality across TRCA’s Jurisdiction. Prepared by Watershed Planning and Ecosystem Science. October, 2021. https://trcaca.s3.ca-central 1.amazonaws.com/app/uploads/2021/10/29113334/2016-2020-SWQ-Report-v11_FINAL_AODA-FA.pdf

- ↑ Environment Canada and Health Canada. 2001. PRIORITY SUBSTANCES LIST ASSESSMENT REPORT. Road Salts. Canadian Environmental Protection Act, 1999. Environment Canada and Health Canada. https://www.canada.ca/content/dam/hc-sc/migration/hc-sc/ewh-semt/alt_formats/hecs-sesc/pdf/pubs/contaminants/psl2-lsp2/road_salt_sels_voirie/road_salt_sels_voirie-eng.pdf

- ↑ Canadian Environmental Protection Act. 1999. Environment Canada and Health Canada, Ottawa, Ontario. https://laws-lois.justice.gc.ca/eng/acts/c-15.31/FullText.html

- ↑ Environment Canada. 2004. Code of Practice for the Environmental Management of Road Salts. Canadian Environmental Protection Act, 1999 (CEPA 1999). April 2004. EPS 1/CC/5. https://publications.gc.ca/collections/collection_2012/ec/En49-31-1-5-eng.pdf

- ↑ Transportation Association Canada (TAC). 2013. Syntheses of Best Practices Road Salt Management - Salt Management Plans. April 2013. https://sustainabletechnologies.ca/app/uploads/2022/02/roadsalt-tac-full-doc.pdf

- ↑ Canadian Council of Ministers of the Environment. 2011. Canadian water quality guidelines for the protection of aquatic life: Chloride. In: Canadian environmental quality guidelines, 1999, Canadian Council of Ministers of the Environment, Winnipeg. https://sustainabletechnologies.ca/app/uploads/2014/05/CWQG_chlorides.pdf

- ↑ Health Canada. 2020. Guidelines for Canadian Drinking Water Quality Summary Table. In collaboration with the Federal-Provincial-Territorial Committee on Drinking Water of the Federal-Provincial-Territorial Committee on Health and the Environment. September 2020. https://www.canada.ca/content/dam/hc-sc/migration/hc-sc/ewh-semt/alt_formats/pdf/pubs/water-eau/sum_guide-res_recom/summary-table-EN-2020-02-11.pdf

- ↑ Wallace, A., Hitch, C., Ruppert, J., Chomicki, K., Cartwright, L., and VanSeters, T. 2022. Freshwater Salinization. Water Canada. January/February 2022. WC122. Digital. https://cdn.watercanada.net/wp-content/uploads/2022/01/17161341/WC122_JanFeb2022_DIGITAL.pdf

- ↑ LSRCA. 2020. Friction and Parking Lots. Technical Bulletin, Volume 3 September 2020. https://sustainabletechnologies.ca/app/uploads/2021/05/Friction-and-Parking-Lots.pdf

- ↑ 21.0 21.1 21.2 Van Seters, T. 2022. Review of Snow and Ice Control Practices on Parking Lots and Walkways. Toronto and Region Conservation Authority, Sustainable Technologies Evaluation Program. Ontario. https://sustainabletechnologies.ca/app/uploads/2022/04/Snow-and-Ice-Control-BMPs-for-Parking-lots-and-Sidewalks.pdf

- ↑ Transportation Association of Canada (TAC). 2013. Syntheses of Best Practices Road Salt Management. April 2013. https://www.tac-atc.ca/sites/tac-atc.ca/files/site/doc/resources/roadsalt-1.pdf

- ↑ Clear Roads. 2022. Research by Topic. Accessed - May 16 2022: https://clearroads.org/research-by-topic/

- ↑ 24.0 24.1 STEP. 2019. Procurement Guidance for Parking Lot Snow and Ice Management. Version 2.0 https://sustainabletechnologies.ca/app/uploads/2019/06/Procurement-Guidance-Parking-Lot-Snow-and-Ice-Mgmt.pdf

- ↑ 25.0 25.1 Kennaley, R. 2021. Legislative solutions to slip and fall liability - Ontario’s Bill 118 marks huge step in the right direction. Landscape Ontario. Accessed - May 8 2022: https://landscapeontario.com/legislative-solutions-to-slip-and-fall-liability

- ↑ LSRCA. 2018. Parking Lot Design Guidelines - Municipal Policy Templates to Promote Salt Reduction in Parking Lots. https://www.lsrca.on.ca/Shared%20Documents/Parking-Lot-Design-Guidelines/Parking%20Lot%20Design%20Guidelines.pdf

- ↑ STEP. 2020. Alternatives to Salt: What else melts snow and ice? Technical Brief. https://sustainabletechnologies.ca/app/uploads/2020/03/Alternatives-to-salt-technical-brief.pdf

- ↑ LSRCA. 2018. Sand versus Salt: Should sand be used for winter maintenance? Technical Bulletin, Volume 1 October 2018. https://sustainabletechnologies.ca/app/uploads/2020/03/Sand-vs-Salt-tech-brief.pdf

- ↑ STEP. 2015. Evaluation of Organic Anti-icing Materials for Winter Maintenance. Technical Brief. Salt Management. https://sustainabletechnologies.ca/app/uploads/2015/11/AlternativeSalt_TechBrief_Nov2015.pdf

- ↑ LSRCA. 2018. Sand versus Salt: Should sand be used for winter maintenance? Technical Bulletin, Volume 1 October 2018. https://sustainabletechnologies.ca/app/uploads/2020/03/Sand-vs-Salt-tech-brief.pdf

- ↑ Environment Canada. 2001. PRIORITY SUBSTANCES LIST ASSESSMENT REPORT. Road Salts. Canadian Environmental Protection Act, 1999. Environment Canada and Health Canada. https://www.canada.ca/content/dam/hc-sc/migration/hc-sc/ewh-semt/alt_formats/hecs-sesc/pdf/pubs/contaminants/psl2-lsp2/road_salt_sels_voirie/road_salt_sels_voirie-eng.pdf

- ↑ Environment Canada. 2004. Code of practice for the Environmental Management of Road Salts. Canadian Environmental Protection Act, 1999 (CEPA 1999). April 2004. EPS 1/CC/5. https://publications.gc.ca/collections/collection_2012/ec/En49-31-1-5-eng.pdf

- ↑ LSRCA. n.d. Parking Lot Design Guidelines. Webpage. Accessed 25, Mar. 25. 2022. https://www.lsrca.on.ca/parking-lot-guidelines

- ↑ LSRCA. 2015.Parking Lot Design Guidelines to Promote Salt Reduction. GHD. 11115623 (2). https://www.lsrca.on.ca/Shared%20Documents/Parking-Lot-Design-Guidelines/Parking-Lot-Guidelines-Salt-Reduction.pdf

- ↑ LSRCA. 2015.Parking Lot Design Guidelines to Promote Salt Reduction. GHD. 11115623 (2). https://www.lsrca.on.ca/Shared%20Documents/Parking-Lot-Design-Guidelines/Parking-Lot-Guidelines-Salt-Reduction.pdf

- ↑ LSRCA. 2015.Parking Lot Design Guidelines to Promote Salt Reduction. GHD. 11115623 (2). https://www.lsrca.on.ca/Shared%20Documents/Parking-Lot-Design-Guidelines/Parking-Lot-Guidelines-Salt-Reduction.pdf

- ↑ LSRCA. 2015.Parking Lot Design Guidelines to Promote Salt Reduction. GHD. 11115623 (2). https://www.lsrca.on.ca/Shared%20Documents/Parking-Lot-Design-Guidelines/Parking-Lot-Guidelines-Salt-Reduction.pdf

- ↑ Ontario Provincial Standard Specification. (2014). Construction Specification and for Seed and Cover OPSS.PROV 804. Retrieved from http://www.raqsb.mto.gov.on.ca/techpubs/ops.nsf/0/3a785d2f480f9349852580820062910a/$FILE/OPSS.PROV 804 Nov2014.pdf

- ↑ Camion™. 2022. Brine Storage Tank. Accessed 28 Mar. 2022. https://www.camionsystems.com/product/brine-storage-tank/

- ↑ LSRCA. 2015.Parking Lot Design Guidelines to Promote Salt Reduction. GHD. 11115623 (2). https://www.lsrca.on.ca/Shared%20Documents/Parking-Lot-Design-Guidelines/Parking-Lot-Guidelines-Salt-Reduction.pdf

- ↑ STEP. 2019. Procurement Guidance for Parking Lot Snow and Ice Management. Version 2.0 https://sustainabletechnologies.ca/app/uploads/2019/06/Procurement-Guidance-Parking-Lot-Snow-and-Ice-Mgmt.pdf

- ↑ STEP. 2019. Procurement Guidance for Parking Lot Snow and Ice Management. Version 2.0 https://sustainabletechnologies.ca/app/uploads/2019/06/Procurement-Guidance-Parking-Lot-Snow-and-Ice-Mgmt.pdf

- ↑ STEP. 2019. Salt Application Best Practices for Winter Maintenance Contracts. Technical Brief. https://sustainabletechnologies.ca/app/uploads/2019/06/Salt-application-best-practices-for-winter-maintenance-contracts-brochure.pdf

- ↑ LSRCA. 2020. Friction and Parking Lots. Technical Bulletin, Volume 3 September 2020. https://sustainabletechnologies.ca/app/uploads/2021/05/Friction-and-Parking-Lots.pdf

- ↑ Tumilty, R. 2018. Rise in road salt prices hits local contractors. Available at: https://www.cbc.ca/news/canada/ottawa/ottawa-contractors-road-salt-price-hike-1.4934369 (Accessed: 24 Mar., 2022)

- ↑ Smart About Salt Council (SASC). n.d. Smart About Salt: Winter Salt Management Program. http://www.smartaboutsalt.com/

- ↑ Smart About Salt Council (SASC). n.d. Smart About Salt: Winter Salt Management Program. http://www.smartaboutsalt.com/

- ↑ STEP. 2016. Salt Application Verified Equipment Program: Managing Risk While Saving Money. Brief. https://sustainabletechnologies.ca/app/uploads/2016/01/Salt-brochures-v11.pdf

- ↑ Conservation Ontario and Ontario Good Roads Assn. 2018. Good Practices for Winter Maintenance in Salt Vulnerable Areas. June, 2018. https://conservationontario.ca/fileadmin/pdf/conservation_authorities_section/SWP_Combined_SVA_Document.pdf

- ↑ Minnesota Pollution Control Agency. 2015. Winter Parking Lot and Sidewalk Maintenance Manual: Reducing Environmental Impacts of Chloride. Third Revision. p-tr1-10. https://www.pca.state.mn.us/sites/default/files/p-tr1-10.pdf.

- ↑ Hintz, W.D. and Relyea, R.A. 2019. A review of the species, community, and ecosystem impacts of road salt salinisation in fresh waters. Freshwater biology, 64(6), pp.1081-1097. https://www.researchgate.net/publication/331991752_A_review_of_the_species_community_and_ecosystem_impacts_of_road_salt_salinisation_in_fresh_waters

- ↑ City of Hamilton. 2021. 2021 Salt Management Plan. https://www.hamilton.ca/sites/default/files/media/browser/2022-01-17/coh-salt-management-plan2021.pdf