Difference between revisions of "Construction"

Kyle menken (talk | contribs) |

Kyle menken (talk | contribs) m |

||

| Line 9: | Line 9: | ||

*'''Lack of planning and communication.''' Poor communication protocols and the pace and extent of construction may preclude proper inspections and certifications. | *'''Lack of planning and communication.''' Poor communication protocols and the pace and extent of construction may preclude proper inspections and certifications. | ||

Regular inspections throughout the construction process of LID practices prevent end products that are not built to the design specifications. Specifically, they ensure that: | |||

*the LID practice has a proper layout, location, footprint, and volume; | |||

*materials meet design specifications; | |||

*the contributing drainage area is stabilized before the LID practice becomes operational; | |||

*environmentally sensitive areas and the LID practices themselves are protected during construction; and | |||

*inlet, outlet, pretreatment, and piped elements have the correct elevations and inverts. | |||

Furthermore, keeping records of these inspections helps to certify the works after construction and makes for a smooth assumption process. | |||

==Construction stages and LID types== | ==Construction stages and LID types== | ||

Revision as of 17:27, 11 August 2022

LID techniques and technologies are new to many municipalities, consulting engineers, and contractors. STEP's construction guidance aims to give practical advice, specific to LID construction, to enable practitioners to successfully construct LID practices.

Common reasons project failure at the construction stage are:

- Lack of detail in designs and construction documents. Contractors can struggle to build LID facilities properly without enough detail in the contract drawings and without guidance and inspection throughout the construction process.

- Lack of knowledge. Designers often do not understand the complexities of the construction process, and contractors often don't understand the purpose of LID practices or the technologies they employ.

- Lack of effective erosion and sediment control during construction. LID practices are most vulnerable to sedimentation and clogging during their own construction or construction of adjacent lands.

- Lack of planning and communication. Poor communication protocols and the pace and extent of construction may preclude proper inspections and certifications.

Regular inspections throughout the construction process of LID practices prevent end products that are not built to the design specifications. Specifically, they ensure that:

- the LID practice has a proper layout, location, footprint, and volume;

- materials meet design specifications;

- the contributing drainage area is stabilized before the LID practice becomes operational;

- environmentally sensitive areas and the LID practices themselves are protected during construction; and

- inlet, outlet, pretreatment, and piped elements have the correct elevations and inverts.

Furthermore, keeping records of these inspections helps to certify the works after construction and makes for a smooth assumption process.

Construction stages and LID types[edit]

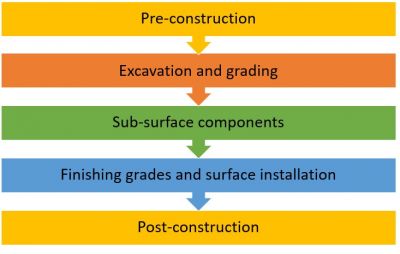

STEP divides the construction process for LID practices into five over-arching stages:

- Pre-construction

- Excavation and grading

- Sub-surface components

- Finishing grades and surface layer installation: vegetated LIDs and finishing grades and surface layer installation: permeable pavements, and

- Post-construction

Most LID practices work at the sub-surface and ground-level by routing stormwater flows from impervious surfaces into excavated or natural depressions or by allowing stormwater to pass through a pervious surface, as is the case with permeable pavements. These depressions are designed and constructed to the meet goals of the LID practice, which may be quality control, quantity control, or water balance restoration. Bioretention gardens, bioswales, rain gardens, enhanced swales, exfiltration trenches, permeable pavements, and infiltration systems (chambers, trenches, and soakaways) all fall into this category.

For this reason, Stages 1-2 and 5 of the LID construction process are fundamentally similar for all sub-surface and ground-level LID types. To illustrate, STEP's recommended processes for excavation do not differ between LID practice types. Excavation procedures are the same, whether for a bioretention garden or a permeable pavement parking lot. On the other hand, stage 4 sub-tasks will vary depending on whether the LID practice's surface is vegetated or permeable pavement. Some sub-tasks in stage 3 will also vary depending on the LID type. For example, permeable pavements often require compaction of sub-surface storage layers. The following sections give a brief description of each over-arching stage, a list of sub-tasks for each stage, and links to the page dedicated to each main LID construction stage.

Green roofs, blue roofs, stormwater planters, and rainwater harvesting systems have specific construction sequences that differ from the main sequence described above. One day we will write guidance for these LID practices as well.

Pre-construction[edit]

Pre-construction activities set the stage for the successful construction of an LID practice. The pre-construction page gives guidance on:

- design verification and site walk-through

- LID construction notes

- tendering and contract

- communication, inspection plan, and utilities coordination

- erosion and sediment control measures

- mobilization, access, staging, and perimeter controls

Excavation and grading[edit]

Excavation and grading are necessary for installing LID practices with sub-surface components, re-grading land to hold more water, and re-routing overland flow routes into an LID practice. The excavation and grading page gives guidance on:

- clearing and grubbing

- excavation and rough grade

- sub-grade

- final excavated grade and verification

Sub-surface components[edit]

Most LID practices use a combination of sub-surface features such as gravel storage reservoirs, liners, underdrains, monitoring wells, and other components to meet their design objectives. The construction process for sub-surface components works from the ground up. While some LID practices include all the sub-surface components listed below, most designs will not include one or more of these layers. Permeable pavements can have different construction requirements at this stage, mostly regarding compaction of sub-surface layers. Installing infiltration chambers also requires guidance specific to that LID type.

The sub-surface components page gives guidance on:

- geotextile

- underdrain

- impermeable liners

- overflow

- monitoring wells

- storage reservoir

- sub-base reservoir (permeable pavements)

- base course (permeable pavements)

- infiltration chamber installation

- stone choker layer

- curbing

- pre-treatment and inlet

Finishing grades and surface layer installation[edit]

This construction stage differs between LID practice type. The finishing grades and surface layer installation: vegetated LIDs page has guidance for vegetated LIDs, and the finishing grades and surface layer installation: permeable pavements page has guidance for and non-vegetated LIDs. In many cases the surface of infiltration systems will be traditional asphalt, concrete, or pavers; STEP does not provide guidance on installing non-permeable surfaces.

| LID practices with vegetated surfaces | Permeable pavements |

|---|---|

| soil media installation and soil amendments | bedding layer |

| finish grading | placement and finishing |

| large stone and riprap | paver installation |

| plant verification and installation | tamping |

| mulch placement | joint cutting |

| stabilizing contributing drainage area and planting adjacent vegetation | joint aggregate |

| -- | curbing |

| -- | stabilizing contributing drainage area |

Post-construction[edit]

Post-construction tasks ensure that the LID practice was built to specs and that any outstanding issues with it are resolved before assumption. The post-construction page give guidance on:

- Addressing deficiencies

- Final certification